SERVICE MANUAL - Alarko Carrier

SERVICE MANUAL - Alarko Carrier

SERVICE MANUAL - Alarko Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

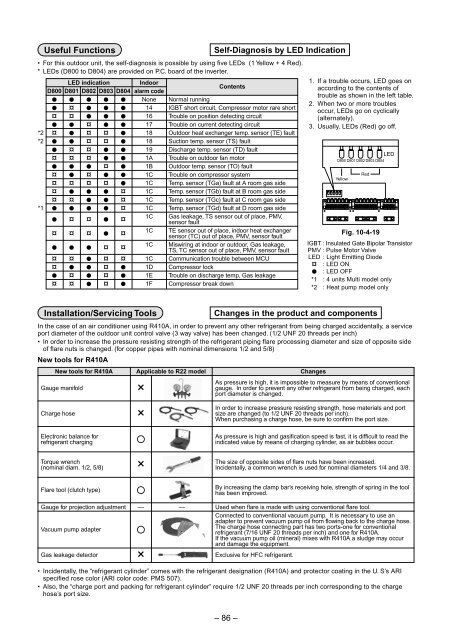

Useful Functions<br />

Self-Diagnosis by LED Indication<br />

• For this outdoor unit, the self-diagnosis is possible by using five LEDs (1 Yellow + 4 Red).<br />

* LEDs (D800 to D804) are provided on P.C. board of the inverter.<br />

*2<br />

*2<br />

*1<br />

LED indication<br />

D800 D801 D802 D803 D804<br />

l l l l l<br />

l ¤ l l l<br />

¤ ¤ l l l<br />

l l ¤ l l<br />

¤ l ¤ ¤ l<br />

l l ¤ ¤ l<br />

l ¤ ¤ l l<br />

¤ ¤ ¤ l l<br />

l l l ¤ l<br />

¤ l ¤ l l<br />

¤ ¤ ¤ ¤ l<br />

¤ l l l ¤<br />

¤ ¤ l l ¤<br />

l l l l ¤<br />

l ¤ ¤ l ¤<br />

¤ ¤ ¤ l ¤<br />

l l l ¤ ¤<br />

¤ ¤ l ¤ ¤<br />

¤ l l ¤ l<br />

l ¤ l ¤ l<br />

¤ ¤ l ¤ l<br />

Indoor<br />

alarm code<br />

None<br />

14<br />

16<br />

17<br />

18<br />

18<br />

19<br />

1A<br />

1B<br />

1C<br />

1C<br />

1C<br />

1C<br />

1C<br />

1C<br />

1C<br />

1C<br />

1C<br />

1D<br />

1E<br />

1F<br />

Contents<br />

Normal running<br />

IGBT short circuit, Compressor motor rare short<br />

Trouble on position detecting circuit<br />

Trouble on current detecting circuit<br />

Outdoor heat exchanger temp. sensor (TE) fault<br />

Suction temp. sensor (TS) fault<br />

Discharge temp. sensor (TD) fault<br />

Trouble on outdoor fan motor<br />

Outdoor temp. sensor (TO) fault<br />

Trouble on compressor system<br />

Temp. sensor (TGa) fault at A room gas side<br />

Temp. sensor (TGb) fault at B room gas side<br />

Temp. sensor (TGc) fault at C room gas side<br />

Temp. sensor (TGd) fault at D room gas side<br />

Gas leakage, TS sensor out of place, PMV,<br />

sensor fault<br />

TE sensor out of place, indoor heat exchanger<br />

sensor (TC) out of place, PMV, sensor fault<br />

Miswiring at indoor or outdoor, Gas leakage,<br />

TS, TC sensor out of place, PMV, sensor fault<br />

Communication trouble between MCU<br />

Compressor lock<br />

Trouble on discharge temp, Gas leakage<br />

Compressor break down<br />

1. If a trouble occurs, LED goes on<br />

according to the contents of<br />

trouble as shown in the left table.<br />

2. When two or more troubles<br />

occur, LEDs go on cyclically<br />

(alternately).<br />

3. Usually, LEDs (Red) go off.<br />

LED<br />

D800 D801 D802 D803 D804<br />

Yellow<br />

Red<br />

Fig. 10-4-19<br />

IGBT : Insulated Gate Bipolar Transistor<br />

PMV : Pulse Motor Valve<br />

LED : Light Emitting Diode<br />

¤ : LED ON<br />

l : LED OFF<br />

*1 : 4 units Multi model only<br />

*2 : Heat pump model only<br />

Installation/Servicing Tools<br />

Changes in the product and components<br />

In the case of an air conditioner using R410A, in order to prevent any other refrigerant from being charged accidentally, a service<br />

port diameter of the outdoor unit control valve (3 way valve) has been changed. (1/2 UNF 20 threads per inch)<br />

• In order to increase the pressure resisting strength of the refrigerant piping flare processing diameter and size of opposite side<br />

of flare nuts is changed. (for copper pipes with nominal dimensions 1/2 and 5/8)<br />

New tools for R410A<br />

New tools for R410A<br />

Gauge manifold<br />

Charge hose<br />

Applicable to R22 model<br />

×<br />

×<br />

Changes<br />

As pressure is high, it is impossible to measure by means of conventional<br />

gauge. In order to prevent any other refrigerant from being charged, each<br />

port diameter is changed.<br />

In order to increase pressure resisting strength, hose materials and port<br />

size are changed (to 1/2 UNF 20 threads per inch).<br />

When purchasing a charge hose, be sure to confirm the port size.<br />

Electronic balance for<br />

refrigerant charging<br />

Torque wrench<br />

(nominal diam. 1/2, 5/8)<br />

Flare tool (clutch type)<br />

¡<br />

×<br />

¡<br />

As pressure is high and gasification speed is fast, it is difficult to read the<br />

indicated value by means of charging cylinder, as air bubbles occur.<br />

The size of opposite sides of flare nuts have been increased.<br />

Incidentally, a common wrench is used for nominal diameters 1/4 and 3/8.<br />

By increasing the clamp bar’s receiving hole, strength of spring in the tool<br />

has been improved.<br />

Gauge for projection adjustment<br />

Vacuum pump adapter<br />

Gas leakage detector<br />

— —<br />

¡<br />

×<br />

Used when flare is made with using conventional flare tool.<br />

Connected to conventional vacuum pump. It is necessary to use an<br />

adapter to prevent vacuum pump oil from flowing back to the charge hose.<br />

The charge hose connecting part has two ports-one for conventional<br />

refrigerant (7/16 UNF 20 threads per inch) and one for R410A.<br />

If the vacuum pump oil (mineral) mixes with R410A a sludge may occur<br />

and damage the equipment.<br />

Exclusive for HFC refrigerant.<br />

• Incidentally, the “refrigerant cylinder” comes with the refrigerant designation (R410A) and protector coating in the U. S’s ARI<br />

specified rose color (ARI color code: PMS 507).<br />

• Also, the “charge port and packing for refrigerant cylinder” require 1/2 UNF 20 threads per inch corresponding to the charge<br />

hose’s port size.<br />

– 86 –