MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

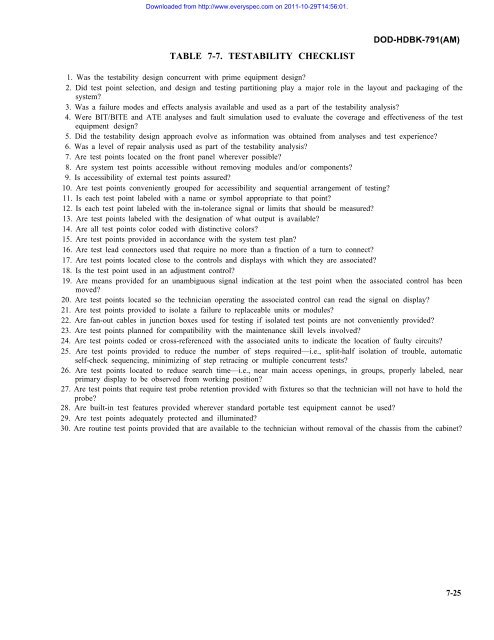

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.TABLE 7-7. TESTABILITY CHECKLISTDOD-HDBK-791(AM)1. Was the testability design concurrent with prime equipment design?2. Did test point selection, and design and testing partitioning play a major role in the layout and packaging of thesystem?3. Was a failure modes and effects analysis available and used as a part of the testability analysis?4. Were BIT/BITE and ATE analyses and fault simulation used to evaluate the coverage and effectiveness of the testequipment design?5. Did the testability design approach evolve as information was obtained from analyses and test experience?6. Was a level of repair analysis used as part of the testability analysis?7. Are test points located on the front panel wherever possible?8. Are system test points accessible without removing modules and/or <strong>com</strong>ponents?9. Is accessibility of external test points assured?10. Are test points conveniently grouped for accessibility and sequential arrangement of testing?11. Is each test point labeled with a name or symbol appropriate to that point?12. Is each test point labeled with the in-tolerance signal or limits that should be measured?13. Are test points labeled with the designation of what output is available?14. Are all test points color coded with distinctive colors?15. Are test points provided in accordance with the system test plan?16. Are test lead connectors used that require no more than a fraction of a turn to connect?17. Are test points located close to the controls and displays with which they are associated?18. Is the test point used in an adjustment control?19. Are means provided for an unambiguous signal indication at the test point when the associated control has beenmoved?20. Are test points located so the technician operating the associated control can read the signal on display?21. Are test points provided to isolate a failure to replaceable units or modules?22. Are fan-out cables in junction boxes used for testing if isolated test points are not conveniently provided?23. Are test points planned for <strong>com</strong>patibility with the maintenance skill levels involved?24. Are test points coded or cross-referenced with the associated units to indicate the location of faulty circuits?25. Are test points provided to reduce the number of steps required—i.e., split-half isolation of trouble, automaticself-check sequencing, minimizing of step retracing or multiple concurrent tests?26. Are test points located to reduce search time—i.e., near main access openings, in groups, properly labeled, nearprimary display to be observed from working position?27. Are test points that require test probe retention provided with fixtures so that the technician will not have to hold theprobe?28. Are built-in test features provided wherever standard portable test equipment cannot be used?29. Are test points adequately protected and illuminated?30. Are routine test points provided that are available to the technician without removal of the chassis from the cabinet?7-25