MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

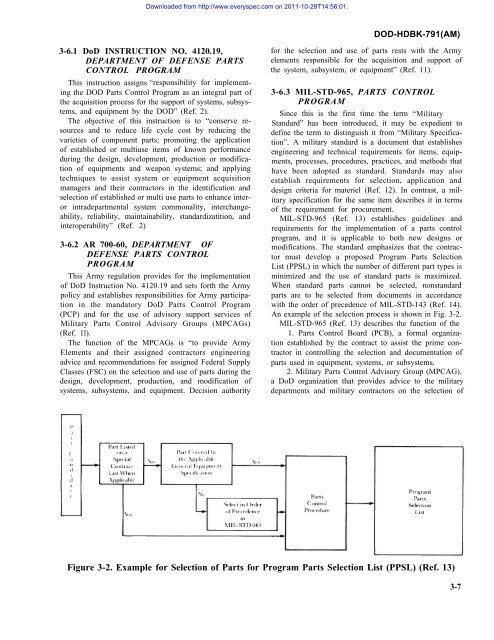

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)3-6.1 DoD INSTRUCTION NO. 4120.19,DEPARTMENT OF DEFENSE PARTSCONTROL PROGRAMThis instruction assigns “responsibility for implementingthe DOD Parts Control Program as an integral part ofthe acquisition process for the support of systems, subsystems,and equipment by the DOD” (Ref. 2).The objective of this instruction is to “conserve resourcesand to reduce life cycle cost by reducing thevarieties of <strong>com</strong>ponent parts; promoting the applicationof established or multiuse items of known performanceduring the design, development, production or modificationof equipments and weapon systems; and applyingtechniques to assist system or equipment acquisitionmanagers and their contractors in the identification andselection of established or multi use parts to enhance interorintradepartmental system <strong>com</strong>monality, interchangeability,reliability, maintainability, standardizatition, andinteroperability” (Ref. 2)3-6.2 AR 700-60, DEPARTMENT OFDEFENSE PARTS CONTROLPROGRAMThis Army regulation provides for the implementationof DoD Instruction No. 4120.19 and sets forth the Armypolicy and establishes responsibilities for Army participationin the mandatory DoD Parts Control Program(PCP) and for the use of advisory support services ofMilitary Parts Control Advisory Groups (MPCAGs)(Ref. 1l).The function of the MPCAGs is “to provide ArmyElements and their assigned contractors engineeringadvice and re<strong>com</strong>mendations for assigned Federal SupplyClasses (FSC) on the selection and use of parts during thedesign, development, production, and modification ofsystems, subsystems, and equipment. Decision authorityfor the selection and use of parts rests with the Armyelements responsible for the acquisition and support ofthe system, subsystem, or equipment” (Ref. 11).3-6.3 MIL-STD-965, PARTS CONTROLPROGRAMSince this is the first time the term “MilitaryStandard” has been introduced, it may be expedient todefine the term to distinguish it from “Military Specification”.A military standard is a document that establishesengineering and technical requirements for items, equipments,processes, procedures, practices, and methods thathave been adopted as standard. Standards may alsoestablish requirements for selection, application anddesign criteria for materiel (Ref. 12). In contrast, a militaryspecification for the same item describes it in termsof the requirement for procurement.MIL-STD-965 (Ref. 13) establishes guidelines andrequirements for the implementation of a parts controlprogram, and it is applicable to both new designs ormodifications. The standard emphasizes that the contractormust develop a proposed Program Parts SelectionList (PPSL) in which the number of different part types isminimized and the use of standard parts is maximized.When standard parts cannot be selected, nonstandardparts are to be selected from documents in accordancewith the order of precedence of MIL-STD-143 (Ref. 14).An example of the selection process is shown in Fig. 3-2.MIL-STD-965 (Ref. 13) describes the function of the1. Parts Control Board (PCB), a formal organizationestablished by the contract to assist the prime contractorin controlling the selection and documentation ofparts used in equipment, systems, or subsystems.2. Military Parts Control Advisory Group (MPCAG),a DoD organization that provides advice to the militarydepartments and military contractors on the selection ofFigure 3-2. Example for Selection of Parts for Program Parts Selection List (PPSL) (Ref. 13)3-7