Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)TABLE 4-7 (cont’d)B. ACCESS DOORS AND COVERS:1. Are clearance holes for mounting screws in cover plates oversize to obviate the need for perfect alignment?2. Are the cases designed to be lifted off units rather than for the units to be lifted out of the cases?3. Are the cases made larger than the units they cover to preclude damage to wires and <strong>com</strong>ponents?4. Are guides or tracks provided to prevent the cocking of the case to one side?5. If the method of opening a cover is not obvious, are instructions provided on the outside of the cover?6. When covers are not in place and secure, are means provided to make this error obvious?7. Are no more than four fasteners used to secure the case?8. Is the same type of fastener used for all covers and cases on given equipment?9. Are ventilation holes with screening of small enough mesh provided to prevent entry of probes or conductors thatcould inadvertently contact high voltages?10. Are access doors made in whatever shape is necessary to permit passage of the <strong>com</strong>ponents and implements thatmust pass through?11. On hinged access doors, is the hinge placed on the bottom or is a prop provided so that the door will remain openwithout being hand-held?12. If maintenance instructions are placed on the door, are letters oriented to be read when door is open?13. Because military equipment must be maintained on ground covered deep in mud or snow, in extreme temperature,and tactical blackout at night, do access doors permit equipment to be maintained from above rather thanbelow and from inside rather than outside?C. HANDLES:1. Are handles used on units weighing over 45 N (10 lb)?2. Are handles provided on smaller units that are difficult to grasp, remove, or hold without using <strong>com</strong>ponents orcontrols as handholds?3. Are handles provided on transit cases to facilitate the handling and carrying of the unit?4. Are handles placed above the center of gravity and positioned for balanced loads?5. For handles requiring a firm grip, are bale openings at least 115 mm (4.5 in.) wide and 50 mm (2.0 in.) deep?6. Do handles have a <strong>com</strong>fortable grip while the unit is being removed or replaced?7. Are handles placed where they will not catch on other units, wiring, or structural members?8. Are recessed handles located near the back of heavy equipment to facilitate handling?9. Are handles located to prevent accidental activation of controls?10. Are handles placed to serve as maintenance stands for equipment?11. For heavy equipment that requires two people for lifting, are four standard size grips or two large size gripsprovided?12. Are handles or other suitable means for grasping, handling, or carrying provided on all units designated to beremoved or replaced?D. WIRE AND CABLE:1. Are electrical cables of sufficient length so that each functioning unit can be checked in a convenient place?2. Is it possible to move units that are difficult to connect, when installed, to convenient positions for connectingand disconnecting?3. Are cables and lines directly accessible to the technician wherever possible, i.e., not under panels or floorboards,which are difficult to remove?4. Are cables routed so they need not be sharply bent or unbent when being connected or disconnected?5. Are cables and wire bundles routed so they cannot be pinched by doors or lids, or so they will not be stepped on orused as handholds by maintenance personnel?6. Are means provided for pulling out drawers and slide-out racks without breaking electrical connections wheninternal, in-service adjustments are required; for reeling cabling when drawers and racks are returned to theirpositions?7. Are parts mounted on one side of a surface with associated wires on the other side?4-30(cont’d on next page)

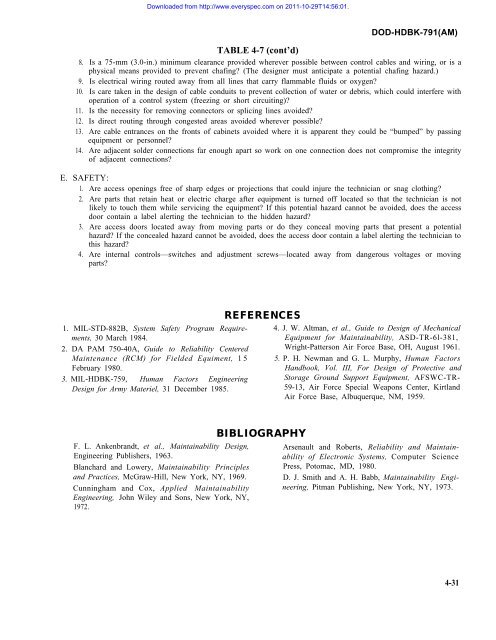

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.8.9.10.11.12.13.14.DOD-HDBK-791(AM)TABLE 4-7 (cont’d)Is a 75-mm (3.0-in.) minimum clearance provided wherever possible between control cables and wiring, or is aphysical means provided to prevent chafing? (The designer must anticipate a potential chafing hazard.)Is electrical wiring routed away from all lines that carry flammable fluids or oxygen?Is care taken in the design of cable conduits to prevent collection of water or debris, which could interfere withoperation of a control system (freezing or short circuiting)?Is the necessity for removing connectors or splicing lines avoided?Is direct routing through congested areas avoided wherever possible?Are cable entrances on the fronts of cabinets avoided where it is apparent they could be “bumped” by passingequipment or personnel?Are adjacent solder connections far enough apart so work on one connection does not <strong>com</strong>promise the integrityof adjacent connections?E. SAFETY:1. Are access openings free of sharp edges or projections that could injure the technician or snag clothing?2. Are parts that retain heat or electric charge after equipment is turned off located so that the technician is notlikely to touch them while servicing the equipment? If this potential hazard cannot be avoided, does the accessdoor contain a label alerting the technician to the hidden hazard?3. Are access doors located away from moving parts or do they conceal moving parts that present a potentialhazard? If the concealed hazard cannot be avoided, does the access door contain a label alerting the technician tothis hazard?4. Are internal controls—switches and adjustment screws—located away from dangerous voltages or movingparts?REFERENCES1. MIL-STD-882B, System Safety Program Require- 4. J. W. Altman, et al., Guide to Design of Mechanicalments, 30 March 1984.Equipment for Maintainability, ASD-TR-6l-381,2. DA PAM 750-40A, Guide to Reliability Centered Wright-Patterson Air Force Base, OH, August 1961.Maintenance (RCM) for Fielded Equiment, 15 5. P. H. Newman and G. L. Murphy, Human FactorsFebruary 1980.Handbook, Vol. III, For Design of Protective and3. MIL-HDBK-759, Human Factors Engineering Storage Ground Support Equipment, AFSWC-TR-Design for Army Materiel, 31 December 1985.59-13, Air Force Special Weapons Center, KirtlandAir Force Base, Albuquerque, NM, 1959.BIBLIOGRAPHYF. L. Ankenbrandt, et al., Maintainability Design, Arsenault and Roberts, Reliability and Maintain-Engineering Publishers, 1963.ability of Electronic Systems, Computer ScienceBlanchard and Lowery, Maintainability Principles Press, Potomac, MD, 1980.and Practices, McGraw-Hill, New York, NY, 1969. D. J. Smith and A. H. Babb, Maintainability Engi-Cunningham and Cox, Applied Maintainability neering, Pitman Publishing, New York, NY, 1973.Engineering, John Wiley and Sons, New York, NY,1972.4-31