MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

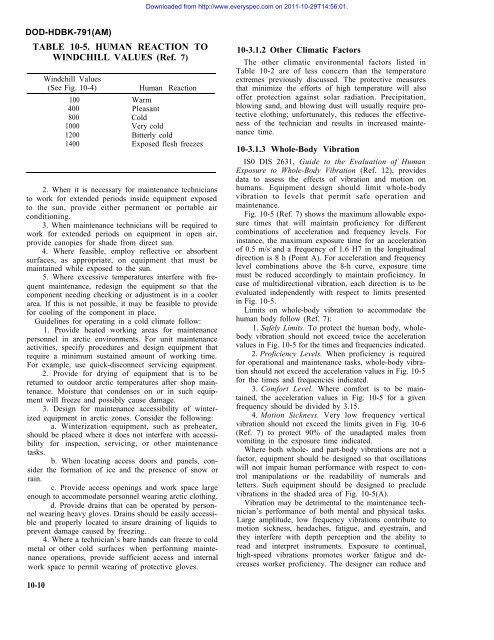

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)TABLE 10-5. HUMAN REACTION TOWINDCHILL VALUES (Ref. 7)Windchill Values(See Fig. 10-4)Human Reaction100 Warm400 Pleasant800 Cold1000 Very cold1200 Bitterly cold1400 Exposed flesh freezes2. When it is necessary for maintenance techniciansto work for extended periods inside equipment exposedto the sun, provide either permanent or portable airconditioning.3. When maintenance technicians will be required towork for extended periods on equipment in open air,provide canopies for shade from direct sun.4. Where feasible, employ reflective or absorbentsurfaces, as appropriate, on equipment that must bemaintained while exposed to the sun.5. Where excessive temperatures interfere with frequentmaintenance, redesign the equipment so that the<strong>com</strong>ponent needing checking or adjustment is in a coolerarea. If this is not possible, it may be feasible to providefor cooling of the <strong>com</strong>ponent in place.Guidelines for operating in a cold climate follow:1. Provide heated working areas for maintenancepersonnel in arctic environments. For unit maintenanceactivities, specify procedures and design equipment thatrequire a minimum sustained amount of working time.For example, use quick-disconnect servicing equipment.2. Provide for drying of equipment that is to bereturned to outdoor arctic temperatures after shop maintenance.Moisture that condenses on or in such equipmentwill freeze and possibly cause damage.3. Design for maintenance accessibility of winterizedequipment in arctic zones. Consider the following:a. Winterization equipment, such as preheater,should be placed where it does not interfere with accessibilityfor inspection, servicing, or other maintenancetasks.b. When locating access doors and panels, considerthe formation of ice and the presence of snow orrain.c. Provide access openings and work space largeenough to ac<strong>com</strong>modate personnel wearing arctic clothing.d. Provide drains that can be operated by personnelwearing heavy gloves. Drains should be easily accessibleand properly located to insure draining of liquids toprevent damage caused by freezing.4. Where a technician’s bare hands can freeze to coldmetal or other cold surfaces when performing maintenanceoperations, provide sufficient access and internalwork space to permit wearing of protective gloves.10-3.1.2 Other Climatic FactorsThe other climatic environmental factors listed inTable 10-2 are of less concern than the temperatureextremes previously discussed. The protective measuresthat minimize the efforts of high temperature will alsooffer protection against solar radiation. Precipitation,blowing sand, and blowing dust will usually require protectiveclothing; unfortunately, this reduces the effectivenessof the technician and results in increased maintenancetime.10-3.1.3 Whole-Body VibrationIS0 DIS 2631, Guide to the Evaluation of HumanExposure to Whole-Body Vibration (Ref. 12), providesdata to assess the effects of vibration and motion onhumans. Equipment design should limit whole-bodyvibration to levels that permit safe operation andmaintenance.Fig. 10-5 (Ref. 7) shows the maximum allowable exposuretimes that will maintain proficiency for different<strong>com</strong>binations of acceleration and frequency levels. Forinstance, the maximum exposure time for an accelerationof 0.5 m/s 2 and a frequency of 1.6 H7 in the longitudinaldirection is 8 h (Point A). For acceleration and frequencylevel <strong>com</strong>binations above the 8-h curve, exposure timemust be reduced accordingly to maintain proficiency. Incase of multidirectional vibration, each direction is to beevaluated independently with respect to limits presentedin Fig. 10-5.Limits on whole-body vibration to ac<strong>com</strong>modate thehuman body follow (Ref. 7):1. Safely Limits. To protect the human body, wholebodyvibration should not exceed twice the accelerationvalues in Fig. 10-5 for the times and frequencies indicated.2. Proficiency Levels. When proficiency is requiredfor operational and maintenance tasks, whole-body vibrationshould not exceed the acceleration values in Fig. 10-5for the times and frequencies indicated.3. Comfort Level. Where <strong>com</strong>fort is to be maintained,the acceleration values in Fig. 10-5 for a givenfrequency should be divided by 3.15.4. Motion Sickness. Very low frequency verticalvibration should not exceed the limits given in Fig. 10-6(Ref. 7) to protect 90% of the unadapted males fromvomiting in the exposure time indicated.Where both whole- and part-body vibrations are not afactor, equipment should be designed so that oscillationswill not impair human performance with respect to controlmanipulations or the readability of numerals andletters. Such equipment should be designed to precludevibrations in the shaded area of Fig. 10-5(A).Vibration may be detrimental to the maintenance technician’sperformance of both mental and physical tasks.Large amplitude, low frequency vibrations contribute tomotion sickness, headaches, fatigue, and eyestrain, andthey interfere with depth perception and the ability toread and interpret instruments. Exposure to continual,high-speed vibrations promotes worker fatigue and decreasesworker proficiency. The designer can reduce and10-10