MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

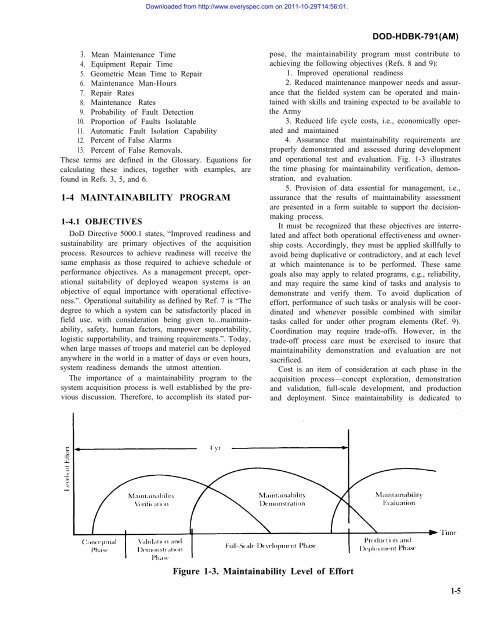

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)3.4.5.6.7.8.9.10.11.12.13.Mean Maintenance TimeEquipment Repair TimeGeometric Mean Time to RepairMaintenance Man-HoursRepair RatesMaintenance RatesProbability of Fault DetectionProportion of Faults IsolatableAutomatic Fault Isolation CapabilityPercent of False AlarmsPercent of False Removals.These terms are defined in the Glossary. Equations forcalculating these indices, together with examples, arefound in Refs. 3, 5, and 6.1-4 <strong>MAINTAINABILITY</strong> PROGRAM1-4.1 OBJECTIVESDoD Directive 5000.1 states, “Improved readiness andsustainability are primary objectives of the acquisitionprocess. Resources to achieve readiness will receive thesame emphasis as those required to achieve schedule orperformance objectives. As a management precept, operationalsuitability of deployed weapon systems is anobjective of equal importance with operational effectiveness.”.Operational suitability as defined by Ref. 7 is “Thedegree to which a system can be satisfactorily placed infield use, with consideration being given to...maintainability,safety, human factors, manpower supportability,logistic supportability, and training requirements.”. Today,when large masses of troops and materiel can be deployedanywhere in the world in a matter of days or even hours,system readiness demands the utmost attention.The importance of a maintainability program to thesystem acquisition process is well established by the previousdiscussion. Therefore, to ac<strong>com</strong>plish its stated pur-pose, the maintainability program must contribute toachieving the following objectives (Refs. 8 and 9):1. Improved operational readiness2. Reduced maintenance manpower needs and assurancethat the fielded system can be operated and maintainedwith skills and training expected to be available tothe Army3. Reduced life cycle costs, i.e., economically operatedand maintained4. Assurance that maintainability requirements areproperly demonstrated and assessed during developmentand operational test and evaluation. Fig. 1-3 illustratesthe time phasing for maintainability verification, demonstration,and evaluation.5. Provision of data essential for management, i.e.,assurance that the results of maintainability assessmentare presented in a form suitable to support the decisionmakingprocess.It must be recognized that these objectives are interrelatedand affect both operational effectiveness and ownershipcosts. Accordingly, they must be applied skillfully toavoid being duplicative or contradictory, and at each levelat which maintenance is to be performed. These samegoals also may apply to related programs, e.g., reliability,and may require the same kind of tasks and analysis todemonstrate and verify them. To avoid duplication ofeffort, performance of such tasks or analysis will be coordinatedand whenever possible <strong>com</strong>bined with similartasks called for under other program elements (Ref. 9).Coordination may require trade-offs. However, in thetrade-off process care must be exercised to insure thatmaintainability demonstration and evaluation are notsacrificed.Cost is an item of consideration at each phase in theacquisition process—concept exploration, demonstrationand validation, full-scale development, and productionand deployment. Since maintainability is dedicated toFigure 1-3. Maintainability Level of Effort1-5