MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

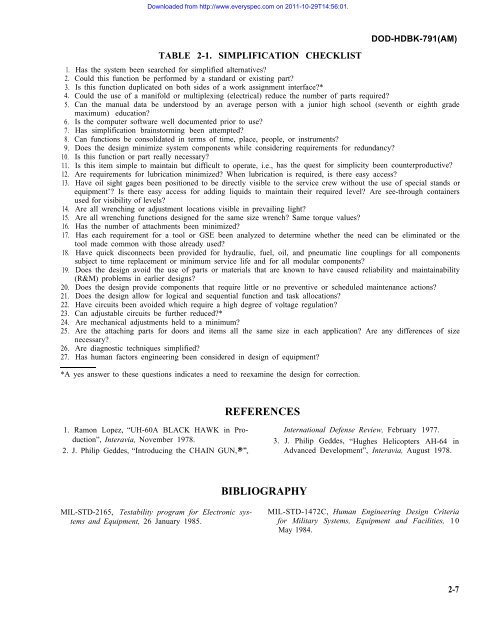

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20.21.22.23.24.25.26.27.TABLE 2-1. SIMPLIFICATION CHECKLISTDOD-HDBK-791(AM)Has the system been searched for simplified alternatives?Could this function be performed by a standard or existing part?Is this function duplicated on both sides of a work assignment interface?*Could the use of a manifold or multiplexing (electrical) reduce the number of parts required?Can the manual data be understood by an average person with a junior high school (seventh or eighth grademaximum) education?Is the <strong>com</strong>puter software well documented prior to use?Has simplification brainstorming been attempted?Can functions be consolidated in terms of time, place, people, or instruments?Does the design minimize system <strong>com</strong>ponents while considering requirements for redundancy?Is this function or part really necessary?Is this item simple to maintain but difficult to operate, i.e., has the quest for simplicity been counterproductive?Are requirements for lubrication minimized? When lubrication is required, is there easy access?Have oil sight gages been positioned to be directly visible to the service crew without the use of special stands orequipment’? Is there easy access for adding liquids to maintain their required level? Are see-through containersused for visibility of levels?Are all wrenching or adjustment locations visible in prevailing light?Are all wrenching functions designed for the same size wrench? Same torque values?Has the number of attachments been minimized?Has each requirement for a tool or GSE been analyzed to determine whether the need can be eliminated or thetool made <strong>com</strong>mon with those already used?Have quick disconnects been provided for hydraulic, fuel, oil, and pneumatic line couplings for all <strong>com</strong>ponentssubject to time replacement or minimum service life and for all modular <strong>com</strong>ponents?Does the design avoid the use of parts or materials that are known to have caused reliability and maintainability(R&M) problems in earlier designs?Does the design provide <strong>com</strong>ponents that require little or no preventive or scheduled maintenance actions?Does the design allow for logical and sequential function and task allocations?Have circuits been avoided which require a high degree of voltage regulation?Can adjustable circuits be further reduced?*Are mechanical adjustments held to a minimum?Are the attaching parts for doors and items all the same size in each application? Are any differences of sizenecessary?Are diagnostic techniques simplified?Has human factors engineering been considered in design of equipment?*A yes answer to these questions indicates a need to reexamine the design for correction.REFERENCES1. Ramon Lopez, “UH-60A BLACK HAWK in Pro- International Defense Review, February 1977.duction”, Interavia, November 1978.3. J. Philip Geddes, “Hughes Helicopters AH-64 in2. J. Philip Geddes, “Introducing the CHAIN GUN, Advanced Development”, Interavia, August 1978.BIBLIOGRAPHYMIL-STD-2165, Testability program for Electronic systemsand Equipment, 26 January 1985.MIL-STD-1472C, Human Engineering Design Criteriafor Military Systems, Equipment and Facilities, 10May 1984.2-7