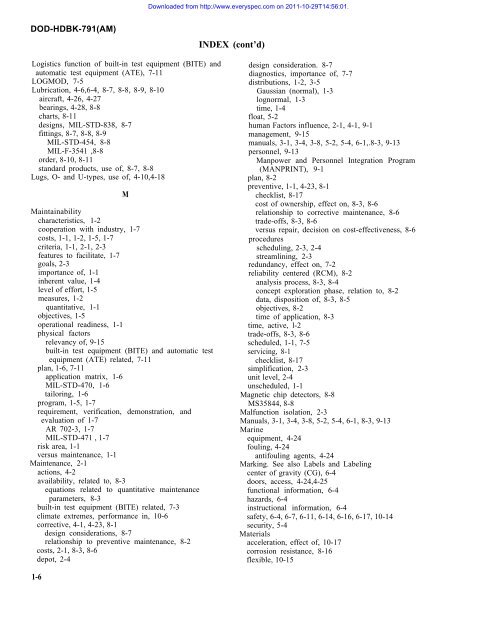

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)INDEX (cont’d)Logistics function of built-in test equipment (BITE) and design consideration. 8-7automatic test equipment (ATE), 7-11LOGMOD, 7-5Lubrication, 4-6,6-4, 8-7, 8-8, 8-9, 8-10aircraft, 4-26, 4-27bearings, 4-28, 8-8charts, 8-11designs, MIL-STD-838, 8-7fittings, 8-7, 8-8, 8-9MIL-STD-454, 8-8MIL-F-3541 ,8-8order, 8-10, 8-11standard products, use of, 8-7, 8-8Lugs, O- and U-types, use of, 4-10,4-18Maintainabilitycharacteristics, 1-2cooperation with industry, 1-7costs, 1-1, 1-2, 1-5, 1-7criteria, 1-1, 2-1, 2-3features to facilitate, 1-7goals, 2-3importance of, 1-1inherent value, 1-4level of effort, 1-5measures, 1-2quantitative, 1-1objectives, 1-5operational readiness, 1-1physical factorsrelevancy of, 9-15built-in test equipment (BITE) and automatic testequipment (ATE) related, 7-11plan, 1-6, 7-11application matrix, 1-6MIL-STD-470, 1-6tailoring, 1-6program, 1-5, 1-7requirement, verification, demonstration, andevaluation of 1-7AR 702-3, 1-7MIL-STD-471 , 1-7risk area, 1-1versus maintenance, 1-1Maintenance, 2-1actions, 4-2availability, related to, 8-3equations related to quantitative maintenanceparameters, 8-3built-in test equipment (BITE) related, 7-3climate extremes, performance in, 10-6corrective, 4-1, 4-23, 8-1design considerations, 8-7relationship to preventive maintenance, 8-2costs, 2-1, 8-3, 8-6depot, 2-41-6Mdiagnostics, importance of, 7-7distributions, 1-2, 3-5Gaussian (normal), 1-3lognormal, 1-3time, 1-4float, 5-2human Factors influence, 2-1, 4-1, 9-1management, 9-15manuals, 3-1, 3-4, 3-8, 5-2, 5-4, 6-1,.8-3, 9-13personnel, 9-13Manpower and Personnel Integration Program(MANPRINT), 9-1plan, 8-2preventive, 1-1, 4-23, 8-1checklist, 8-17cost of ownership, effect on, 8-3, 8-6relationship to corrective maintenance, 8-6trade-offs, 8-3, 8-6versus repair, decision on cost-effectiveness, 8-6proceduresscheduling, 2-3, 2-4streamlining, 2-3redundancy, effect on, 7-2reliability centered (RCM), 8-2analysis process, 8-3, 8-4concept exploration phase, relation to, 8-2data, disposition of, 8-3, 8-5objectives, 8-2time of application, 8-3time, active, l-2trade-offs, 8-3, 8-6scheduled, 1-1, 7-5servicing, 8-1checklist, 8-17simplification, 2-3unit level, 2-4unscheduled, 1-1Magnetic chip detectors, 8-8MS35844, 8-8Malfunction isolation, 2-3Manuals, 3-1, 3-4, 3-8, 5-2, 5-4, 6-1, 8-3, 9-13Marineequipment, 4-24fouling, 4-24antifouling agents, 4-24Marking. See also Labels and Labelingcenter of gravity (CG), 6-4doors, access, 4-24,4-25functional information, 6-4hazards, 6-4instructional information, 6-4safety, 6-4, 6-7, 6-11, 6-14, 6-16, 6-17, 10-14security, 5-4Materialsacceleration, effect of, 10-17corrosion resistance, 8-16flexible, 10-15

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)INDEX (cont’d)fungous inert, 10-13metals, precious, 5-4, 10-17paints, lacquers, varnishes, 10-14rubber, 10-14Metalsdissimilar, 6-6, 8-14, 8-15, 10-13precious, 5-4, 10-17Meters. 10-16readout, 7-16Microbiological organisms, 10-2Microwave radiation, 10-4, 10-5Military environment, 10-2, 10-3, 10-4, 10-5Military Occupational Specialty (MOS), 9-13Military Occupational Specialty Code (MOSC), 9-13Missiles, 4-20, 9-1Mobile equipment, design, 4-20Modification, 5-2Modular design, 5-9Modularization, 2-2, 5-1. See also Modules andThrowaway itemsadvantages, 5-1, 5-2checklist, 5-16design guidelines, 5-6examples of techniquearmament, 5-9electronics and electrical equipment, 5-6helicopter engine, 5-13missiles and rockets, 5-9tank-automotive, 5-9functional grouping forcircuits, 5-5, 5-7<strong>com</strong>ponents, 5-5, 5-7evaluation of techniques, 5-5frequency of replacement, 5-5logical flow, 5-4standard construction, 5-5tank engine assembly, 5-9, 5-10testability and diagnostics, related to, 7-2vehicle design, 5-6Modules. See a/so Modularization and Throwawayitemsautomatic test equipment (ATE) related, 7-8cost considerations. 5-1criteria for use, 5-4definition, 5-1disposal, 5-4encapsulation, 5-4independent check capability, 5-6interchangeability, 5-1Navy Standard Electronic Module Program (SEM),5-7plug in, 4-2replacement, 5-1self-isolating, 7-13software, 5-3throwaway, 5-3, 5-4trade-off with piece part, 5-4weight limitations, 5-5, 5-6Moisture, 4-4, 10-13. See also Humidityprotection against, 8-15, 10-13Molded-in identification label, 6-6Monitoring equipment, on-line, 7-7Motion sickness, 10-10, 10-12Motivation, 9-13Motors, 8-7, 10-23Mounting, blind. See Blind mountingsNNacelles, engines, 4-28Nameplates. See Labels and LabelingNational Codification Bureau Code (NCBC), 3-3, 3-9National Item Identification Number (NIIN), 3-9National Stock Number, 3-6, 3-8, 3-9, 6-5Navy Standard Electronic Module Program (SEM), 5-Noise, 9-11, 9-12Nondestructive testing, 7-7Nondevelopment Item (NDI), 10-1Nuclear radiationenvironment, 10-15hazard warning symbol, 6-17Numeral and letter sizes, 6-12, 6-13, 6-14Nuts, 4-8Oilfilters, 4-23,4-24,4-28levels, 8-10pressure, 8-8standard products, use of, 8-7, 8-8Openings. See DoorsOzone, 8-15, 10-20OPackaging for access, 4-1Paint, 10-14antifouling, 4-24Parts Control Board, 3-7Partsaccess to, 2-3configuration, 2-3identification, 1-7, 6-1information sources on control ofMilitary Parts Control Advisory Group (MPAG),37MIL-STD-143, 3-6, 3-7, 3-8MIL-STD-965, 1-7Program Parts Selection List (PPSL), 4-23SB 700-20, 3-8marking, 6-5. See also Labels and Labelingnumbering system, 3-9Photocontact, 6-7Photoetching, 6-7Plastic covers, 4-3PI-7

- Page 3 and 4:

Downloaded from http://www.everyspe

- Page 6:

Downloaded from http://www.everyspe

- Page 9 and 10:

Downloaded from http://www.everyspe

- Page 11 and 12:

Downloaded from http://www.everyspe

- Page 13 and 14:

Downloaded from http://www.everyspe

- Page 15 and 16:

Downloaded from http://www.everyspe

- Page 17 and 18:

Downloaded from http://www.everyspe

- Page 19 and 20:

Downloaded from http://www.everyspe

- Page 21 and 22:

Downloaded from http://www.everyspe

- Page 23 and 24:

Downloaded from http://www.everyspe

- Page 25 and 26:

Downloaded from http://www.everyspe

- Page 27 and 28:

Downloaded from http://www.everyspe

- Page 29 and 30:

Downloaded from http://www.everyspe

- Page 31 and 32:

Downloaded from http://www.everyspe

- Page 33 and 34:

Downloaded from http://www.everyspe

- Page 35 and 36:

Downloaded from http://www.everyspe

- Page 37 and 38:

Downloaded from http://www.everyspe

- Page 39 and 40:

Downloaded from http://www.everyspe

- Page 41 and 42:

Downloaded from http://www.everyspe

- Page 43 and 44:

Downloaded from http://www.everyspe

- Page 45 and 46:

Downloaded from http://www.everyspe

- Page 47 and 48:

Downloaded from http://www.everyspe

- Page 49 and 50:

Downloaded from http://www.everyspe

- Page 51 and 52:

Downloaded from http://www.everyspe

- Page 53 and 54:

Downloaded from http://www.everyspe

- Page 55 and 56:

Downloaded from http://www.everyspe

- Page 57 and 58:

Downloaded from http://www.everyspe

- Page 59 and 60:

Downloaded from http://www.everyspe

- Page 61 and 62:

Downloaded from http://www.everyspe

- Page 63 and 64:

Downloaded from http://www.everyspe

- Page 65 and 66:

Downloaded from http://www.everyspe

- Page 67 and 68:

Downloaded from http://www.everyspe

- Page 69 and 70:

Downloaded from http://www.everyspe

- Page 71 and 72:

Downloaded from http://www.everyspe

- Page 73 and 74:

Downloaded from http://www.everyspe

- Page 75 and 76:

Downloaded from http://www.everyspe

- Page 77 and 78:

Downloaded from http://www.everyspe

- Page 79 and 80:

Downloaded from http://www.everyspe

- Page 81 and 82:

Downloaded from http://www.everyspe

- Page 83 and 84:

Downloaded from http://www.everyspe

- Page 85 and 86:

Downloaded from http://www.everyspe

- Page 87 and 88:

Downloaded from http://www.everyspe

- Page 89 and 90:

Downloaded from http://www.everyspe

- Page 91 and 92:

Downloaded from http://www.everyspe

- Page 93 and 94:

Downloaded from http://www.everyspe

- Page 95 and 96:

Downloaded from http://www.everyspe

- Page 97 and 98:

Downloaded from http://www.everyspe

- Page 99 and 100:

Downloaded from http://www.everyspe

- Page 101 and 102:

Downloaded from http://www.everyspe

- Page 103 and 104:

Downloaded from http://www.everyspe

- Page 105 and 106:

Downloaded from http://www.everyspe

- Page 107 and 108:

Downloaded from http://www.everyspe

- Page 109 and 110:

Downloaded from http://www.everyspe

- Page 111 and 112:

Downloaded from http://www.everyspe

- Page 113 and 114:

Downloaded from http://www.everyspe

- Page 115 and 116:

Downloaded from http://www.everyspe

- Page 117 and 118:

Downloaded from http://www.everyspe

- Page 119 and 120:

Downloaded from http://www.everyspe

- Page 121 and 122:

Downloaded from http://www.everyspe

- Page 123 and 124:

Downloaded from http://www.everyspe

- Page 125 and 126:

Downloaded from http://www.everyspe

- Page 127 and 128:

Downloaded from http://www.everyspe

- Page 129 and 130:

Downloaded from http://www.everyspe

- Page 131 and 132:

Downloaded from http://www.everyspe

- Page 133 and 134:

Downloaded from http://www.everyspe

- Page 135 and 136:

Downloaded from http://www.everyspe

- Page 137 and 138:

Downloaded from http://www.everyspe

- Page 139 and 140:

Downloaded from http://www.everyspe

- Page 141 and 142:

Downloaded from http://www.everyspe

- Page 143 and 144:

Downloaded from http://www.everyspe

- Page 145 and 146:

Downloaded from http://www.everyspe

- Page 147 and 148:

Downloaded from http://www.everyspe

- Page 149 and 150:

Downloaded from http://www.everyspe

- Page 151 and 152:

Downloaded from http://www.everyspe

- Page 153 and 154:

Downloaded from http://www.everyspe

- Page 155 and 156:

Downloaded from http://www.everyspe

- Page 157 and 158:

Downloaded from http://www.everyspe

- Page 159 and 160:

Downloaded from http://www.everyspe

- Page 161 and 162:

Downloaded from http://www.everyspe

- Page 163 and 164:

Downloaded from http://www.everyspe

- Page 165 and 166:

Downloaded from http://www.everyspe

- Page 167 and 168:

Downloaded from http://www.everyspe

- Page 169 and 170:

Downloaded from http://www.everyspe

- Page 171 and 172:

Downloaded from http://www.everyspe

- Page 173 and 174: Downloaded from http://www.everyspe

- Page 175 and 176: Downloaded from http://www.everyspe

- Page 177 and 178: Downloaded from http://www.everyspe

- Page 179 and 180: Downloaded from http://www.everyspe

- Page 181 and 182: Downloaded from http://www.everyspe

- Page 183 and 184: Downloaded from http://www.everyspe

- Page 185 and 186: Downloaded from http://www.everyspe

- Page 187 and 188: Downloaded from http://www.everyspe

- Page 189 and 190: Downloaded from http://www.everyspe

- Page 191 and 192: Downloaded from http://www.everyspe

- Page 193 and 194: Downloaded from http://www.everyspe

- Page 195 and 196: Downloaded from http://www.everyspe

- Page 197 and 198: Downloaded from http://www.everyspe

- Page 199 and 200: Downloaded from http://www.everyspe

- Page 201 and 202: Downloaded from http://www.everyspe

- Page 203 and 204: Downloaded from http://www.everyspe

- Page 205 and 206: Downloaded from http://www.everyspe

- Page 207 and 208: Downloaded from http://www.everyspe

- Page 209 and 210: Downloaded from http://www.everyspe

- Page 211 and 212: Downloaded from http://www.everyspe

- Page 213 and 214: Downloaded from http://www.everyspe

- Page 215 and 216: Downloaded from http://www.everyspe

- Page 217 and 218: Downloaded from http://www.everyspe

- Page 219 and 220: Downloaded from http://www.everyspe

- Page 221 and 222: Downloaded from http://www.everyspe

- Page 223: Downloaded from http://www.everyspe

- Page 227 and 228: Downloaded from http://www.everyspe

- Page 229 and 230: Downloaded from http://www.everyspe

- Page 231 and 232: Downloaded from http://www.everyspe