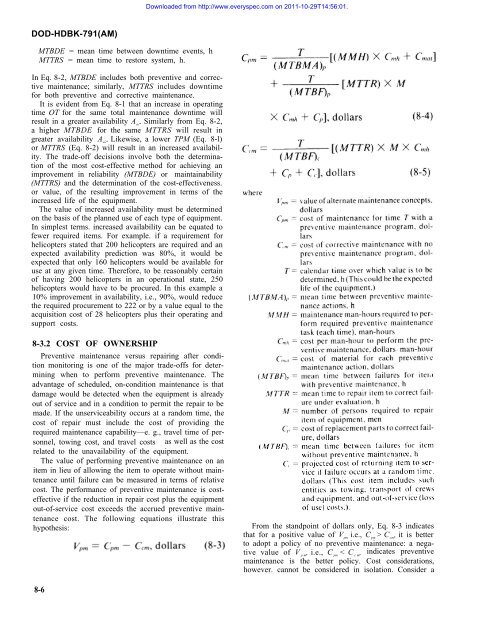

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)MTBDE = mean time between downtime events, hMTTRS = mean time to restore system, h.In Eq. 8-2, MTBDE includes both preventive and correctivemaintenance; similarly, MTTRS includes downtimefor both preventive and corrective maintenance.It is evident from Eq. 8-1 that an increase in operatingtime OT for the same total maintenance downtime willresult in a greater availability A a1. Similarly from Eq. 8-2,a higher MTBDE for the same MTTRS will result ingreater availability A a2. Likewise, a lower TPM (Eq. 8-l)or MTTRS (Eq. 8-2) will result in an increased availability.The trade-off decisions involve both the determinationof the most cost-effective method for achieving animprovement in reliability (MTBDE) or maintainability(MTTRS) and the determination of the cost-effectiveness.or value, of the resulting improvement in terms of theincreased life of the equipment.The value of increased availability must be determinedon the basis of the planned use of each type of equipment.In simplest terms. increased availability can be equated tofewer required items. For example. if a requirement forhelicopters stated that 200 helicopters are required and anexpected availability prediction was 80%, it would beexpected that only 160 helicopters would be available foruse at any given time. Therefore, to be reasonably certainof having 200 helicopters in an operational state, 250helicopters would have to be procured. In this example a10% improvement in availability, i.e., 90%, would reducethe required procurement to 222 or by a value equal to theacquisition cost of 28 helicopters plus their operating andsupport costs.8-3.2 COST OF OWNERSHIPPreventive maintenance versus repairing after conditionmonitoring is one of the major trade-offs for determiningwhen to perform preventive maintenance. Theadvantage of scheduled, on-condition maintenance is thatdamage would be detected when the equipment is alreadyout of service and in a condition to permit the repair to bemade. If the unserviceability occurs at a random time, thecost of repair must include the cost of providing therequired maintenance capability—e. g., travel time of personnel,towing cost, and travel costs as well as the costrelated to the unavailability of the equipment.The value of performing preventive maintenance on anitem in lieu of allowing the item to operate without maintenanceuntil failure can be measured in terms of relativecost. The performance of preventive maintenance is costeffectiveif the reduction in repair cost plus the equipmentout-of-service cost exceeds the accrued preventive maintenancecost. The following equations illustrate thishypothesis:From the standpoint of dollars only, Eq. 8-3 indicatesthat for a positive value of V pmi.e., C pm> C cm, it is betterto adopt a policy of no preventive maintenance: a negativevalue of V pm, i.e., C pm< C cm, indicates preventivemaintenance is the better policy. Cost considerations,however. cannot be considered in isolation. Consider a8-6

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)fan or alternalor belt; wear to failure without preventivemaintenance may be the less expensive option rather thanreplacement at a fixed number of’ miles. However, whenthe belt breaks even though a replacement belt andpersonnel are immediately available to make the repairthe equipment is down for a finite time period. Dependingon the circumstances, the interruption of function providedby the disabled equipment may be intolerable.Cost-effectiveness also is a factor in evaluating a proposedchange to improve the maintenance capabilityand or reduce the preventive maintenance requirements.The cost-saving ratio, i.e., the cost saving divided by theoriginal cost, is a measure of maintenance cost-effectiveness.The cost of improvement includes the cost of designchanges, cost of new parts and perhaps new test equipmentand technical manuals, and cost of incorporation.As previously indicated, cost may not be the sole measureof effectiveness. In the example in par. 8-2.4 the questionwas “to redesign the equipment to provide a test or inspectioncapability or to live with the inherent reliability characteristicsand risks”. Hovever, unless the improvementis introduced early in design, the cost of redesign andretrofit may be greater than the dollars saved by requiringless maintenance effort. Increased availability, and itsvalue in terms of reduced equipment procurement, isoften a more significant cost-saying factor than a reductionin maintenance man-hours.8-4 <strong>DESIGN</strong> CONSIDERATIONSDesign considerations for preventive maintenance aregenerally the same as those for corrective maintenance.Access for replacement will usually provide sufficientaccess for periodic inspection, cleaning, and adjustmentas well. Instrumentation for fault isolation can also providefor condition monitoring. Periodic servicing ofequipment imposes other criteria that are discussed in theparagraphs that follow.Servicing of mechanical equipment is important toassure that the equipment achieves the expected usefullife. Ease of servicing is important in reducing downtimesand cost of ownership. A major reason for the high cost ofmaintenance is the repetitive frequency—some of whichmay be unnecessary—of service tasks. Ease of servicing isprovided by ease of access to servicing points and by useof standard servicing features for a large population ofitems—e.g., lubrication fittings, servicing locations, <strong>com</strong>monlubricants, and fuels.Periodic servicing is important because of the possibilityand danger of impairing overall weapon system effectivenessif the servicing is not performed. All militarymateriel is serviced on a systematic schedule. One or moreof the following service operations are usually performed:1. Lubrication—Oiling and greasing, and filling anddraining2. Cleaning and preserving3. Adjusting and aligning.Different types of equipment require different predominanttypes of service. For example, motor vehiclesrequire frequent lubrication and occasional cleaning andadjusting. Gun systems and missiles are more prone torequire preserving. at least during peacetime. Ground testequipment requires adjusting and aligning to maintaincalibration. Peacetime operations place a strong emphasison cleaning and preserving stored equipment to preventdegradation.8-4.1 LUBRICATION8-4.1.1 Oiling and GreasingOiling and greasing (lubrication) of equipment is ofvital importance. The best designed mechanical and electricmechanical equipment can and does fail <strong>com</strong>pletelydue to inadequate and/or improper lubrication. Lubricationis often the only maintenance required for long,maintenance-free service. Equipment designs often evolvewith little thought given to the vast number of maintenancehours required in the field for periodic checking ofoil levels and lubrication. Lubricant-free designs and, orrapid lubrication capability should be built into theequipment and given equal design importance with theproper functioning of the equipment. Lubrication requirementsfor mechanical items—bearings, gears, shafts—isusually recognized. There are particular lubrication requirementsfor electronic and electrical equipment. Synchronousswitch shafts, generators, motors, and relayarms have been a serious source of malfunction and ofsubsequent destruction of the equipment.Working surfaces subject to wear or deteriorationshould be provided with the appropriate means of lubrication.Lubricants, fluids, and associated products shouldbe selected in accordance with the provisions of US ArmyMateriel Development and Readiness Command (DAR-COM) Regulation 750-11 (Ref. 1l). This regulation establishesthe Belvoir RD&E Center as the AMC focal pointon the proper selection and use of the packaged productsit governs. In this role the center’s Fuels and LubricationDivision provides the coordination and approval necessaryto insure that lubricant orders and technical manualscontain only current standardized product specifications.The regulation1. Explicitly prohibits the random introduction ofproprietary products2. Requires <strong>com</strong>pelling justification for the use ofnonstandard products as opposed to those qualified inaccordance with military and, or federal specifications, orpurchase descriptions3. Imposes MIL-STD-838 (Ref. 12) on all designs,developments, and acquisitions4. Insists that all procurement requests, solicitations,and contracts have lubricant order or technicalmanual approval before acceptance of the first unit.From the maintainability standpoint equipment shouldbe designed to use only one type of oil and one type ofgrease. The types should be the same as those for otherequipment to be used in the same operational locations.Where a special lubricant is required, such as high or lowtemperature operational requirements, each lubricationfitting should be clearly labeled with the grease or oil8-7