MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

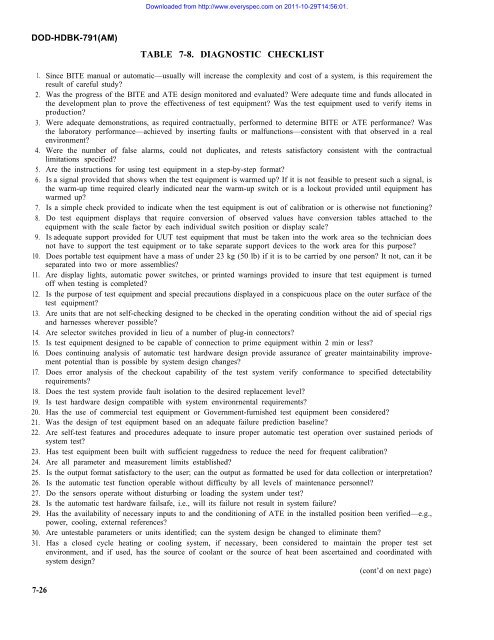

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)TABLE 7-8. DIAGNOSTIC CHECKLIST1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20.21.22.23.24.25.26.27.28.29.30.31.7-26Since BITE manual or automatic—usually will increase the <strong>com</strong>plexity and cost of a system, is this requirement theresult of careful study?Was the progress of the BITE and ATE design monitored and evaluated? Were adequate time and funds allocated inthe development plan to prove the effectiveness of test equipment? Was the test equipment used to verify items inproduction?Were adequate demonstrations, as required contractually, performed to determine BITE or ATE performance? Wasthe laboratory performance—achieved by inserting faults or malfunctions—consistent with that observed in a realenvironment?Were the number of false alarms, could not duplicates, and retests satisfactory consistent with the contractuallimitations specified?Are the instructions for using test equipment in a step-by-step format?IS a signal provided that shows when the test equipment is warmed up? If it is not feasible to present such a signal, isthe warm-up time required clearly indicated near the warm-up switch or is a lockout provided until equipment haswarmed up?Is a simple check provided to indicate when the test equipment is out of calibration or is otherwise not functioning?Do test equipment displays that require conversion of observed values have conversion tables attached to theequipment with the scale factor by each individual switch position or display scale?IS adequate support provided for UUT test equipment that must be taken into the work area so the technician doesnot have to support the test equipment or to take separate support devices to the work area for this purpose?Does portable test equipment have a mass of under 23 kg (50 lb) if it is to be carried by one person? It not, can it beseparated into two or more assemblies?Are display lights, automatic power switches, or printed warnings provided to insure that test equipment is turnedoff when testing is <strong>com</strong>pleted?Is the purpose of test equipment and special precautions displayed in a conspicuous place on the outer surface of thetest equipment?Are units that are not self-checking designed to be checked in the operating condition without the aid of special rigsand harnesses wherever possible?Are selector switches provided in lieu of a number of plug-in connectors?Is test equipment designed to be capable of connection to prime equipment within 2 min or less?Does continuing analysis of automatic test hardware design provide assurance of greater maintainability improvementpotential than is possible by system design changes?Does error analysis of the checkout capability of the test system verify conformance to specified detectabilityrequirements?Does the test system provide fault isolation to the desired replacement level?Is test hardware design <strong>com</strong>patible with system environrnental requirements?Has the use of <strong>com</strong>mercial test equipment or Government-furnished test equipment been considered?Was the design of test equipment based on an adequate failure prediction baseline?Are self-test features and procedures adequate to insure proper automatic test operation over sustained periods ofsystem test?Has test equipment been built with sufficient ruggedness to reduce the need for frequent calibration?Are all parameter and measurement limits established?Is the output format satisfactory to the user; can the output as formatted be used for data collection or interpretation?Is the automatic test function operable without difficulty by all levels of maintenance personnel?Do the sensors operate without disturbing or loading the system under test?Is the automatic test hardware failsafe, i.e., will its failure not result in system failure?Has the availability of necessary inputs to and the conditioning of ATE in the installed position been verified—e.g.,power, cooling, external references?Are untestable parameters or units identified; can the system design be changed to eliminate them?Has a closed cycle heating or cooling system, if necessary, been considered to maintain the proper test setenvironment, and if used, has the source of coolant or the source of heat been ascertained and coordinated withsystem design?(cont’d on next page)