MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

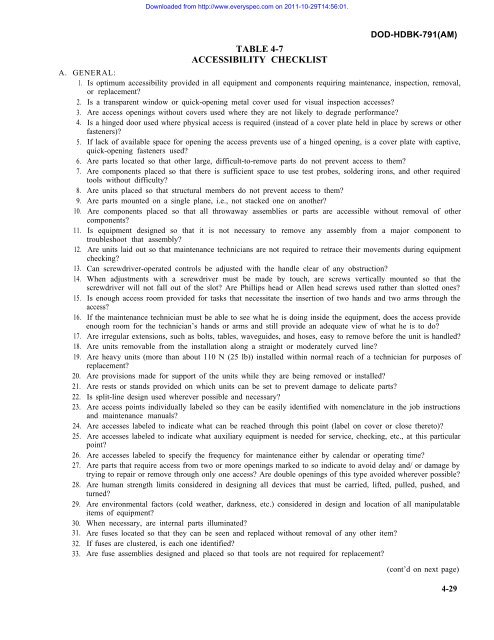

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.A. GENERAL:1.2.3.4.5.6.7.8.9.10.11.12.13.14.15.16.17.18.19.20.21.22.23.24.25.26.27.28.29.30.31.32.33.TABLE 4-7ACCESSIBILITY CHECKLISTDOD-HDBK-791(AM)Is optimum accessibility provided in all equipment and <strong>com</strong>ponents requiring maintenance, inspection, removal,or replacement?Is a transparent window or quick-opening metal cover used for visual inspection accesses?Are access openings without covers used where they are not likely to degrade performance?Is a hinged door used where physical access is required (instead of a cover plate held in place by screws or otherfasteners)?If lack of available space for opening the access prevents use of a hinged opening, is a cover plate with captive,quick-opening fasteners used?Are parts located so that other large, difficult-to-remove parts do not prevent access to them?Are <strong>com</strong>ponents placed so that there is sufficient space to use test probes, soldering irons, and other requiredtools without difficulty?Are units placed so that structural members do not prevent access to them?Are parts mounted on a single plane, i.e., not stacked one on another?Are <strong>com</strong>ponents placed so that all throwaway assemblies or parts are accessible without removal of other<strong>com</strong>ponents?Is equipment designed so that it is not necessary to remove any assembly from a major <strong>com</strong>ponent totroubleshoot that assembly?Are units laid out so that maintenance technicians are not required to retrace their movements during equipmentchecking?Can screwdriver-operated controls be adjusted with the handle clear of any obstruction?When adjustments with a screwdriver must be made by touch, are screws vertically mounted so that thescrewdriver will not fall out of the slot? Are Phillips head or Allen head screws used rather than slotted ones?Is enough access room provided for tasks that necessitate the insertion of two hands and two arms through theaccess?If the maintenance technician must be able to see what he is doing inside the equipment, does the access provideenough room for the technician’s hands or arms and still provide an adequate view of what he is to do?Are irregular extensions, such as bolts, tables, waveguides, and hoses, easy to remove before the unit is handled?Are units removable from the installation along a straight or moderately curved line?Are heavy units (more than about 110 N (25 lb)) installed within normal reach of a technician for purposes ofreplacement?Are provisions made for support of the units while they are being removed or installed?Are rests or stands provided on which units can be set to prevent damage to delicate parts?Is split-line design used wherever possible and necessary?Are access points individually labeled so they can be easily identified with nomenclature in the job instructionsand maintenance manuals?Are accesses labeled to indicate what can be reached through this point (label on cover or close thereto)?Are accesses labeled to indicate what auxiliary equipment is needed for service, checking, etc., at this particularpoint?Are accesses labeled to specify the frequency for maintenance either by calendar or operating time?Are parts that require access from two or more openings marked to so indicate to avoid delay and/ or damage bytrying to repair or remove through only one access? Are double openings of this type avoided wherever possible?Are human strength limits considered in designing all devices that must be carried, lifted, pulled, pushed, andturned?Are environmental factors (cold weather, darkness, etc.) considered in design and location of all manipulatableitems of equipment?When necessary, are internal parts illuminated?Are fuses located so that they can be seen and replaced without removal of any other item?If fuses are clustered, is each one identified?Are fuse assemblies designed and placed so that tools are not required for replacement?(cont’d on next page)4-29