MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

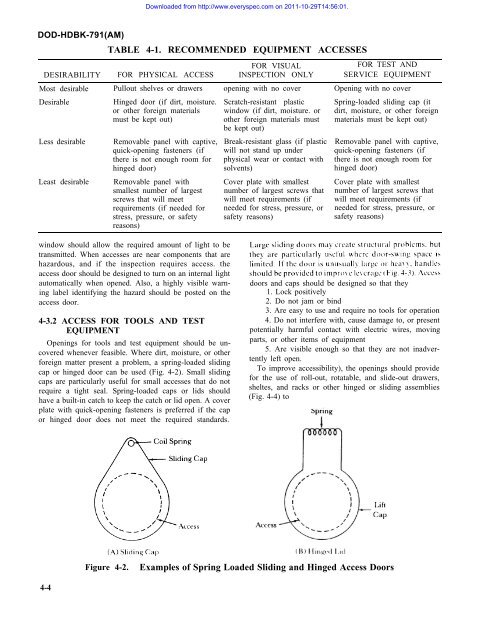

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)DESIRABILITYMost desirableDesirableLess desirableLeast desirableTABLE 4-1. RECOMMENDED EQUIPMENT ACCESSESFOR VISUALFOR TEST ANDFOR PHYSICAL ACCESS INSPECTION ONLY SERVICE EQUIPMENTPullout shelves or drawersHinged door (if dirt, moisture.or other foreign materialsmust be kept out)Removable panel with captive,quick-opening fasteners (ifthere is not enough room forhinged door)Removable panel withsmallest number of largestscrews that will meetrequirements (if needed forstress, pressure, or safetyreasons)opening with no coverScratch-resistant plasticwindow (if dirt, moisture. orother foreign materials mustbe kept out)Break-resistant glass (if plasticwill not stand up underphysical wear or contact withsolvents)Cover plate with smallestnumber of largest screws thatwill meet requirements (ifneeded for stress, pressure, orsafety reasons)Opening with no coverSpring-loaded sliding cap (itdirt, moisture, or other foreignmaterials must be kept out)Removable panel with captive,quick-opening fasteners (ifthere is not enough room forhinged door)Cover plate with smallestnumber of largest screws thatwill meet requirements (ifneeded for stress, pressure, orsafety reasons)window should allow the required amount of light to betransmitted. When accesses are near <strong>com</strong>ponents that arehazardous, and if the inspection requires access. theaccess door should be designed to turn on an internal lightautomatically when opened. Also, a highly visible warninglabel identifying the hazard should be posted on theaccess door.4-3.2 ACCESS FOR TOOLS AND TESTEQUIPMENTOpenings for tools and test equipment should be uncoveredwhenever feasible. Where dirt, moisture, or otherforeign matter present a problem, a spring-loaded slidingcap or hinged door can be used (Fig. 4-2). Small slidingcaps are particularly useful for small accesses that do notrequire a tight seal. Spring-loaded caps or lids shouldhave a built-in catch to keep the catch or lid open. A coverplate with quick-opening fasteners is preferred if the capor hinged door does not meet the required standards.doors and caps should be designed so that they1. Lock positively2. Do not jam or bind3. Are easy to use and require no tools for operation4. Do not interfere with, cause damage to, or presentpotentially harmful contact with electric wires, movingparts, or other items of equipment5. Are visible enough so that they are not inadvertentlyleft open.To improve accessibility), the openings should providefor the use of roll-out, rotatable, and slide-out drawers,sheltes, and racks or other hinged or sliding assemblies(Fig. 4-4) toFigure 4-2.Examples of Spring Loaded Sliding and Hinged Access Doors4-4