MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

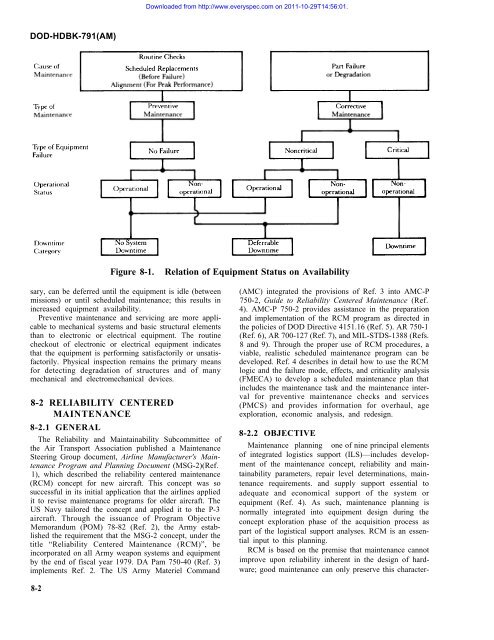

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)Figure 8-1.Relation of Equipment Status on Availabilitysary, can be deferred until the equipment is idle (betweenmissions) or until scheduled maintenance; this results inincreased equipment availability.Preventive maintenance and servicing are more applicableto mechanical systems and basic structural elementsthan to electronic or electrical equipment. The routinecheckout of electronic or electrical equipment indicatesthat the equipment is performing satisfactorily or unsatisfactorily.Physical inspection remains the primary meansfor detecting degradation of structures and of manymechanical and electromechanical devices.8-2 RELIABILITY CENTEREDMAINTENANCE8-2.1 GENERALThe Reliability and Maintainability Sub<strong>com</strong>mittee ofthe Air Transport Association published a MaintenanceSteering Group document, Airline Manufacturer's MaintenanceProgram and Planning Document (MSG-2)(Ref.1), which described the reliability centered maintenance(RCM) concept for new aircraft. This concept was sosuccessful in its initial application that the airlines appliedit to revise maintenance programs for older aircraft. TheUS Navy tailored the concept and applied it to the P-3aircraft. Through the issuance of Program ObjectiveMemorandum (POM) 78-82 (Ref. 2), the Army establishedthe requirement that the MSG-2 concept, under thetitle “Reliability Centered Maintenance (RCM)”, beincorporated on all Army weapon systems and equipmentby the end of fiscal year 1979. DA Pam 750-40 (Ref. 3)implements Ref. 2. The US Army Materiel Command(AMC) integrated the provisions of Ref. 3 into AMC-P750-2, Guide to Reliability Centered Maintenance (Ref.4). AMC-P 750-2 provides assistance in the preparationand implementation of the RCM program as directed inthe policies of DOD Directive 4151.16 (Ref. 5). AR 750-1(Ref. 6), AR 700-127 (Ref. 7), and MIL-STDS-1388 (Refs.8 and 9). Through the proper use of RCM procedures, aviable, realistic scheduled maintenance program can bedeveloped. Ref. 4 describes in detail how to use the RCMlogic and the failure mode, effects, and criticality analysis(FMECA) to develop a scheduled maintenance plan thatincludes the maintenance task and the maintenance intervalfor preventive maintenance checks and services(PMCS) and provides information for overhaul, ageexploration, economic analysis, and redesign.8-2.2 OBJECTIVEMaintenance planning one of nine principal elementsof integrated logistics support (ILS)—includes developmentof the maintenance concept, reliability and maintainabilityparameters, repair level determinations, maintenancerequirements. and supply support essential toadequate and economical support of the system orequipment (Ref. 4). As such, maintenance planning isnormally integrated into equipment design during theconcept exploration phase of the acquisition process aspart of the logistical support analyses. RCM is an essentialinput to this planning.RCM is based on the premise that maintenance cannotimprove upon reliability inherent in the design of hardware;good maintenance can only preserve this character-8-2