MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

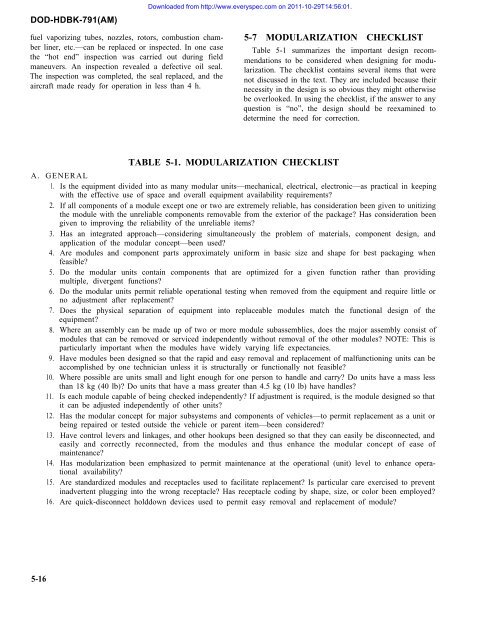

DOD-HDBK-791(AM)Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.fuel vaporizing tubes, nozzles, rotors, <strong>com</strong>bustion chamberliner, etc.—can be replaced or inspected. In one casethe “hot end” inspection was carried out during fieldmaneuvers. An inspection revealed a defective oil seal.The inspection was <strong>com</strong>pleted, the seal replaced, and theaircraft made ready for operation in less than 4 h.5-7 MODULARIZATION CHECKLISTTable 5-1 summarizes the important design re<strong>com</strong>mendationsto be considered when designing for modularization.The checklist contains several items that werenot discussed in the text. They are included because theirnecessity in the design is so obvious they might otherwisebe overlooked. In using the checklist, if the answer to anyquestion is “no”, the design should be reexamined todetermine the need for correction.TABLE 5-1. MODULARIZATION CHECKLISTA. GENERAL1. Is the equipment divided into as many modular units—mechanical, electrical, electronic—as practical in keepingwith the effective use of space and overall equipment availability requirements?2. If all <strong>com</strong>ponents of a module except one or two are extremely reliable, has consideration been given to unitizingthe module with the unreliable <strong>com</strong>ponents removable from the exterior of the package? Has consideration beengiven to improving the reliability of the unreliable items?3. Has an integrated approach—considering simultaneously the problem of materials, <strong>com</strong>ponent design, andapplication of the modular concept—been used?4. Are modules and <strong>com</strong>ponent parts approximately uniform in basic size and shape for best packaging whenfeasible?5. Do the modular units contain <strong>com</strong>ponents that are optimized for a given function rather than providingmultiple, divergent functions?6. Do the modular units permit reliable operational testing when removed from the equipment and require little orno adjustment after replacement?7. Does the physical separation of equipment into replaceable modules match the functional design of theequipment?8. Where an assembly can be made up of two or more module subassemblies, does the major assembly consist ofmodules that can be removed or serviced independently without removal of the other modules? NOTE: This isparticularly important when the modules have widely varying life expectancies.9. Have modules been designed so that the rapid and easy removal and replacement of malfunctioning units can beac<strong>com</strong>plished by one technician unless it is structurally or functionally not feasible?10. Where possible are units small and light enough for one person to handle and carry? Do units have a mass lessthan 18 kg (40 lb)? Do units that have a mass greater than 4.5 kg (10 lb) have handles?11. Is each module capable of being checked independently? If adjustment is required, is the module designed so thatit can be adjusted independently of other units?12. Has the modular concept for major subsystems and <strong>com</strong>ponents of vehicles—to permit replacement as a unit orbeing repaired or tested outside the vehicle or parent item—been considered?13. Have control levers and linkages, and other hookups been designed so that they can easily be disconnected, andeasily and correctly reconnected, from the modules and thus enhance the modular concept of ease ofmaintenance?14. Has modularization been emphasized to permit maintenance at the operational (unit) level to enhance operationalavailability?15. Are standardized modules and receptacles used to facilitate replacement? Is particular care exercised to preventinadvertent plugging into the wrong receptacle? Has receptacle coding by shape, size, or color been employed?16. Are quick-disconnect holddown devices used to permit easy removal and replacement of module?5-16