MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

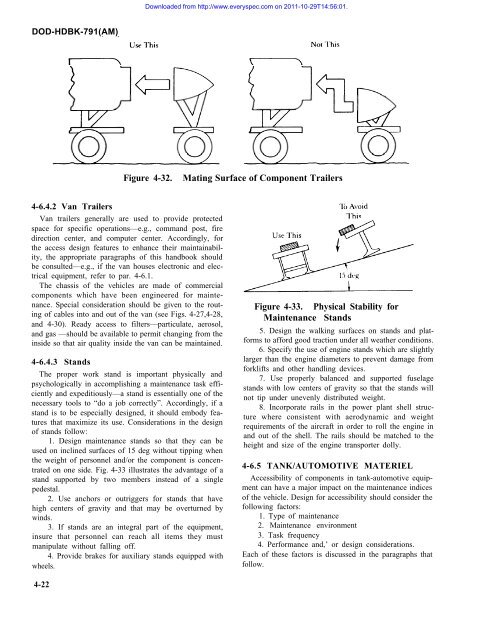

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)Figure 4-32.Mating Surface of Component Trailers4-6.4.2 Van TrailersVan trailers generally are used to provide protectedspace for specific operations—e.g., <strong>com</strong>mand post, firedirection center, and <strong>com</strong>puter center. Accordingly, forthe access design features to enhance their maintainability,the appropriate paragraphs of this handbook shouldbe consulted—e.g., if the van houses electronic and electricalequipment, refer to par. 4-6.1.The chassis of the vehicles are made of <strong>com</strong>mercial<strong>com</strong>ponents which have been engineered for maintenance.Special consideration should be given to the routingof cables into and out of the van (see Figs. 4-27,4-28,and 4-30). Ready access to filters—particulate, aerosol,and gas —should be available to permit changing from theinside so that air quality inside the van can be maintained.4-6.4.3 StandsThe proper work stand is important physically andpsychologically in ac<strong>com</strong>plishing a maintenance task efficientlyand expeditiously—a stand is essentially one of thenecessary tools to “do a job correctly”. Accordingly, if astand is to be especially designed, it should embody featuresthat maximize its use. Considerations in the designof stands follow:1. Design maintenance stands so that they can beused on inclined surfaces of 15 deg without tipping whenthe weight of personnel and/or the <strong>com</strong>ponent is concentratedon one side. Fig. 4-33 illustrates the advantage of astand supported by two members instead of a singlepedestal.2. Use anchors or outriggers for stands that havehigh centers of gravity and that may be overturned bywinds.3. If stands are an integral part of the equipment,insure that personnel can reach all items they mustmanipulate without falling off.4. Provide brakes for auxiliary stands equipped withwheels.Figure 4-33. Physical Stability forMaintenance Stands5. Design the walking surfaces on stands and platformsto afford good traction under all weather conditions.6. Specify the use of engine stands which are slightlylarger than the engine diameters to prevent damage fromforklifts and other handling devices.7. Use properly balanced and supported fuselagestands with low centers of gravity so that the stands willnot tip under unevenly distributed weight.8. Incorporate rails in the power plant shell structurewhere consistent with aerodynamic and weightrequirements of the aircraft in order to roll the engine inand out of the shell. The rails should be matched to theheight and size of the engine transporter dolly.4-6.5 TANK/AUTOMOTIVE MATERIELAccessibility of <strong>com</strong>ponents in tank-automotive equipmentcan have a major impact on the maintenance indicesof the vehicle. Design for accessibility should consider thefollowing factors:1. Type of maintenance2. Maintenance environment3. Task frequency4. Performance and,’ or design considerations.Each of these factors is discussed in the paragraphs thatfollow.4-22