MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

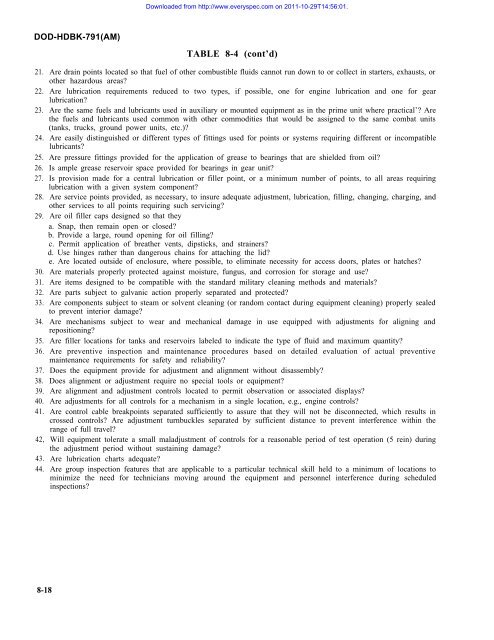

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)21.22.23.24.25.26.27.28.29.30.31.32.33.34.35.36.37.38.39.40.41.42,43.44.TABLE 8-4 (cont’d)Are drain points located so that fuel of other <strong>com</strong>bustible fluids cannot run down to or collect in starters, exhausts, orother hazardous areas?Are lubrication requirements reduced to two types, if possible, one for engine lubrication and one for gearlubrication?Are the same fuels and lubricants used in auxiliary or mounted equipment as in the prime unit where practical’? Arethe fuels and lubricants used <strong>com</strong>mon with other <strong>com</strong>modities that would be assigned to the same <strong>com</strong>bat units(tanks, trucks, ground power units, etc.)?Are easily distinguished or different types of fittings used for points or systems requiring different or in<strong>com</strong>patiblelubricants?Are pressure fittings provided for the application of grease to bearings that are shielded from oil?Is ample grease reservoir space provided for bearings in gear unit?Is provision made for a central lubrication or filler point, or a minimum number of points, to all areas requiringlubrication with a given system <strong>com</strong>ponent?Are service points provided, as necessary, to insure adequate adjustment, lubrication, filling, changing, charging, andother services to all points requiring such servicing?Are oil filler caps designed so that theya. Snap, then remain open or closed?b. Provide a large, round opening for oil filling?c. Permit application of breather vents, dipsticks, and strainers?d. Use hinges rather than dangerous chains for attaching the lid?e. Are located outside of enclosure, where possible, to eliminate necessity for access doors, plates or hatches?Are materials properly protected against moisture, fungus, and corrosion for storage and use?Are items designed to be <strong>com</strong>patible with the standard military cleaning methods and materials?Are parts subject to galvanic action properly separated and protected?Are <strong>com</strong>ponents subject to steam or solvent cleaning (or random contact during equipment cleaning) properly sealedto prevent interior damage?Are mechanisms subject to wear and mechanical damage in use equipped with adjustments for aligning andrepositioning?Are filler locations for tanks and reservoirs labeled to indicate the type of fluid and maximum quantity?Are preventive inspection and maintenance procedures based on detailed evaluation of actual preventivemaintenance requirements for safety and reliability?Does the equipment provide for adjustment and alignment without disassembly?Does alignment or adjustment require no special tools or equipment?Are alignment and adjustment controls located to permit observation or associated displays?Are adjustments for all controls for a mechanism in a single location, e.g., engine controls?Are control cable breakpoints separated sufficiently to assure that they will not be disconnected, which results incrossed controls? Are adjustment turnbuckles separated by sufficient distance to prevent interference within therange of full travel?Will equipment tolerate a small maladjustment of controls for a reasonable period of test operation (5 rein) duringthe adjustment period without sustaining damage?Are lubrication charts adequate?Are group inspection features that are applicable to a particular technical skill held to a minimum of locations tominimize the need for technicians moving around the equipment and personnel interference during scheduledinspections?8-18