MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

MAINTAINABILITY DESIGN TECHNIQUES METRIC - AcqNotes.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

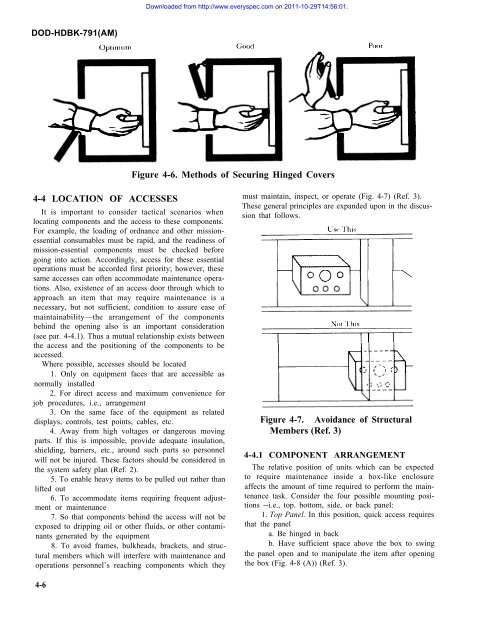

Downloaded from http://www.everyspec.<strong>com</strong> on 2011-10-29T14:56:01.DOD-HDBK-791(AM)Figure 4-6. Methods of Securing Hinged Covers4-4 LOCATION OF ACCESSESIt is important to consider tactical scenarios whenlocating <strong>com</strong>ponents and the access to these <strong>com</strong>ponents.For example, the loading of ordnance and other missionessentialconsumables must be rapid, and the readiness ofmission-essential <strong>com</strong>ponents must be checked beforegoing into action. Accordingly, access for these essentialoperations must be accorded first priority; however, thesesame accesses can often ac<strong>com</strong>modate maintenance operations.Also, existence of an access door through which toapproach an item that may require maintenance is anecessary, but not sufficient, condition to assure ease ofmaintainability—the arrangement of the <strong>com</strong>ponentsbehind the opening also is an important consideration(see par. 4-4.1). Thus a mutual relationship exists betweenthe access and the positioning of the <strong>com</strong>ponents to beaccessed.Where possible, accesses should be located1. Only on equipment faces that are accessible asnormally installed2. For direct access and maximum convenience forjob procedures, i.e., arrangement3. On the same face of the equipment as relateddisplays, controls, test points, cables, etc.4. Away from high voltages or dangerous movingparts. If this is impossible, provide adequate insulation,shielding, barriers, etc., around such parts so personnelwill not be injured. These factors should be considered inthe system safety plan (Ref. 2).5. To enable heavy items to be pulled out rather thanlifted out6. To ac<strong>com</strong>modate items requiring frequent adjustmentor maintenance7. So that <strong>com</strong>ponents behind the access will not beexposed to dripping oil or other fluids, or other contaminantsgenerated by the equipment8. To avoid frames, bulkheads, brackets, and structuralmembers which will interfere with maintenance andoperations personnel’s reaching <strong>com</strong>ponents which theymust maintain, inspect, or operate (Fig. 4-7) (Ref. 3).These general principles are expanded upon in the discussionthat follows.Figure 4-7. Avoidance of StructuralMembers (Ref. 3)4-4.1 COMPONENT ARRANGEMENTThe relative position of units which can be expectedto require maintenance inside a box-like enclosureaffects the amount of time required to perform the maintenancetask. Consider the four possible mounting positions--i.e., top. bottom, side, or back panel:1. Top Panel. In this position, quick access requiresthat the panela. Be hinged in backb. Have sufficient space above the box to swingthe panel open and to manipulate the item after openingthe box (Fig. 4-8 (A)) (Ref. 3).4-6