research activities in 2007 - CSEM

research activities in 2007 - CSEM

research activities in 2007 - CSEM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TUGON – Compact MEMS-based Spectrometers for Infra-Red Spectroscopy<br />

M. Tormen, R. Lockhart, J-M, Mayor, R. P. Stanley<br />

Deformable MEMS diffraction grat<strong>in</strong>gs have great promise as tun<strong>in</strong>g elements for external cavity lasers and for compact spectrometers. The<br />

challenge is to make high efficiency tunable MEMS grat<strong>in</strong>gs and <strong>in</strong>corporate them <strong>in</strong>to practical devices. <strong>CSEM</strong> has successfully designed,<br />

fabricated and tested MEMS grat<strong>in</strong>gs. Their spectral response has been tested and the potential to design ultra-compact spectrometers based<br />

around this technology has been shown.<br />

In Optical MEMS, the family of diffractive MEMS is <strong>in</strong>terest<strong>in</strong>g<br />

for a wide range of applications because they can be<br />

compact, fast and their narrow spectra response can be used<br />

<strong>in</strong> spectrometers and for tunable lasers [1] . Commercially<br />

available diffractive MEMS are used <strong>in</strong> displays, <strong>in</strong><br />

spectroscopy and optical telecommunications [2, 3] .<br />

Optical grat<strong>in</strong>g<br />

Comb drives<br />

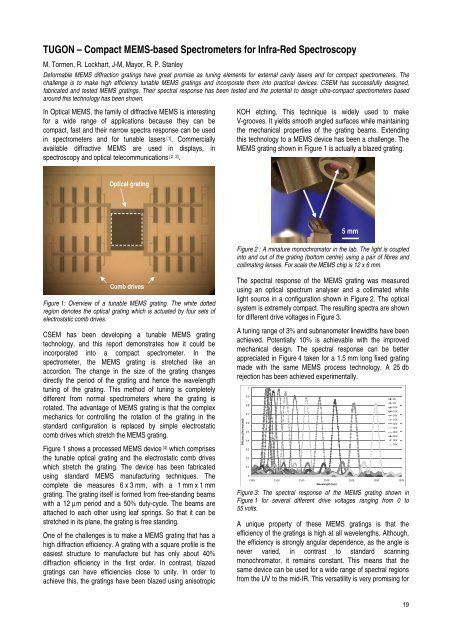

Figure 1: Overview of a tunable MEMS grat<strong>in</strong>g. The white dotted<br />

region denotes the optical grat<strong>in</strong>g which is actuated by four sets of<br />

electrostatic comb drives.<br />

<strong>CSEM</strong> has been develop<strong>in</strong>g a tunable MEMS grat<strong>in</strong>g<br />

technology, and this report demonstrates how it could be<br />

<strong>in</strong>corporated <strong>in</strong>to a compact spectrometer. In the<br />

spectrometer, the MEMS grat<strong>in</strong>g is stretched like an<br />

accordion. The change <strong>in</strong> the size of the grat<strong>in</strong>g changes<br />

directly the period of the grat<strong>in</strong>g and hence the wavelength<br />

tun<strong>in</strong>g of the grat<strong>in</strong>g. This method of tun<strong>in</strong>g is completely<br />

different from normal spectrometers where the grat<strong>in</strong>g is<br />

rotated. The advantage of MEMS grat<strong>in</strong>g is that the complex<br />

mechanics for controll<strong>in</strong>g the rotation of the grat<strong>in</strong>g <strong>in</strong> the<br />

standard configuration is replaced by simple electrostatic<br />

comb drives which stretch the MEMS grat<strong>in</strong>g.<br />

Figure 1 shows a processed MEMS device [4] which comprises<br />

the tunable optical grat<strong>in</strong>g and the electrostatic comb drives<br />

which stretch the grat<strong>in</strong>g. The device has been fabricated<br />

us<strong>in</strong>g standard MEMS manufactur<strong>in</strong>g techniques. The<br />

complete die measures 6 x 3 mm, with a 1 mm x 1 mm<br />

grat<strong>in</strong>g. The grat<strong>in</strong>g itself is formed from free-stand<strong>in</strong>g beams<br />

with a 12 µm period and a 50% duty-cycle. The beams are<br />

attached to each other us<strong>in</strong>g leaf spr<strong>in</strong>gs. So that it can be<br />

stretched <strong>in</strong> its plane, the grat<strong>in</strong>g is free stand<strong>in</strong>g.<br />

One of the challenges is to make a MEMS grat<strong>in</strong>g that has a<br />

high diffraction efficiency. A grat<strong>in</strong>g with a square profile is the<br />

easiest structure to manufacture but has only about 40%<br />

diffraction efficiency <strong>in</strong> the first order. In contrast, blazed<br />

grat<strong>in</strong>gs can have efficiencies close to unity. In order to<br />

achieve this, the grat<strong>in</strong>gs have been blazed us<strong>in</strong>g anisotropic<br />

KOH etch<strong>in</strong>g. This technique is widely used to make<br />

V-grooves. It yields smooth angled surfaces while ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g<br />

the mechanical properties of the grat<strong>in</strong>g beams. Extend<strong>in</strong>g<br />

this technology to a MEMS device has been a challenge. The<br />

MEMS grat<strong>in</strong>g shown <strong>in</strong> Figure 1 is actually a blazed grat<strong>in</strong>g.<br />

Figure 2 : A m<strong>in</strong>ature monochromator <strong>in</strong> the lab. The light is coupled<br />

<strong>in</strong>to and out of the grat<strong>in</strong>g (bottom centre) us<strong>in</strong>g a pair of fibres and<br />

collimat<strong>in</strong>g lenses. For scale the MEMS chip is 12 x 6 mm.<br />

The spectral response of the MEMS grat<strong>in</strong>g was measured<br />

us<strong>in</strong>g an optical spectrum analyser and a collimated white<br />

light source <strong>in</strong> a configuration shown <strong>in</strong> Figure 2. The optical<br />

system is extremely compact. The result<strong>in</strong>g spectra are shown<br />

for different drive voltages <strong>in</strong> Figure 3.<br />

A tun<strong>in</strong>g range of 3% and subnanometer l<strong>in</strong>ewidths have been<br />

achieved. Potentially 10% is achievable with the improved<br />

mechanical design. The spectral response can be better<br />

appreciated <strong>in</strong> Figure 4 taken for a 1.5 mm long fixed grat<strong>in</strong>g<br />

made with the same MEMS process technology. A 25 db<br />

rejection has been achieved experimentally.<br />

Efficiency (Normalized)<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

5 mm<br />

1505 1510 1515 1520<br />

Wavelength (nm)<br />

1525 1530 1535<br />

Figure 3: The spectral response of the MEMS grat<strong>in</strong>g shown <strong>in</strong><br />

Figure 1 for several different drive voltages rang<strong>in</strong>g from 0 to<br />

55 volts.<br />

A unique property of these MEMS grat<strong>in</strong>gs is that the<br />

efficiency of the grat<strong>in</strong>gs is high at all wavelengths. Although,<br />

the efficiency is strongly angular dependence, as the angle is<br />

never varied, <strong>in</strong> contrast to standard scann<strong>in</strong>g<br />

monochromator, it rema<strong>in</strong>s constant. This means that the<br />

same device can be used for a wide range of spectral regions<br />

from the UV to the mid-IR. This versatility is very promis<strong>in</strong>g for<br />

0V<br />

5V<br />

10V<br />

15V<br />

20V<br />

25V<br />

30V<br />

35V<br />

40V<br />

45V<br />

50V<br />

55V<br />

19