research activities in 2007 - CSEM

research activities in 2007 - CSEM

research activities in 2007 - CSEM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Composite Materials for Bone Implants<br />

M. Giazzon, M. Liley, G. Weder<br />

<strong>CSEM</strong> is develop<strong>in</strong>g methods to nanostructure (‘texture’) composite materials for use <strong>in</strong> orthopaedic implants. Photolithography and bead<br />

lithography methods are used to create master templates that are then replicated <strong>in</strong> a res<strong>in</strong> matrix. The structures will be tested for their effect on<br />

bone cells <strong>in</strong> vitro.<br />

The use of orthopaedic surgery to replace jo<strong>in</strong>ts and repair<br />

bone defects is <strong>in</strong>creas<strong>in</strong>g rapidly. Due to a more active ag<strong>in</strong>g<br />

population, the demands made on the materials used <strong>in</strong> these<br />

operations are also <strong>in</strong>creas<strong>in</strong>g: improved robustness, longer<br />

lifetimes and easier surgical procedures are expected for hip<br />

implants and other jo<strong>in</strong>t replacements.<br />

Metals have been used with enormous success <strong>in</strong> orthopaedic<br />

surgery, but there are still some problems associated with<br />

their use. While issues such as weight and thermal<br />

conductivity can be important for specific applications such as<br />

cranial repair, one major issue of almost universal importance<br />

is that of Young’s modulus. The high stiffness of metallic<br />

implants results <strong>in</strong> a mismatch <strong>in</strong> its mechanical properties<br />

and surround<strong>in</strong>g bone. This <strong>in</strong> turn leads to “stress shield<strong>in</strong>g”:<br />

loss of bone mass and weaken<strong>in</strong>g of the surround<strong>in</strong>g bone<br />

that may lead to implant failure. In this context, the repair of<br />

osteoporotic bone rema<strong>in</strong>s a major challenge.<br />

As a partner <strong>in</strong> the EU project Newbone, <strong>CSEM</strong> is work<strong>in</strong>g to<br />

develop composite materials that can be used <strong>in</strong> orthopaedic<br />

surgery. Glass-fibre re<strong>in</strong>forced composites (FRCs) based on<br />

polymeric materials currently used <strong>in</strong> dentistry are be<strong>in</strong>g<br />

tested and optimised for applications <strong>in</strong> bone repair. <strong>CSEM</strong>’s<br />

contribution is to test the effect of surface coat<strong>in</strong>gs and<br />

modification, with the goal of develop<strong>in</strong>g surface micro- and<br />

nanostructures that enhance cell growth, cell adhesion and<br />

the <strong>in</strong>tegration of the implant <strong>in</strong>to the surround<strong>in</strong>g bone.<br />

Figure 1: Hemispherical pits fabricated by replication <strong>in</strong> a bis-<br />

GMA/TEGDMA res<strong>in</strong> matrix<br />

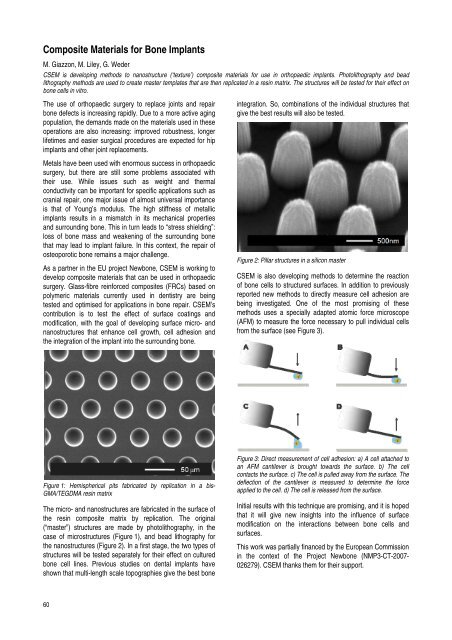

The micro- and nanostructures are fabricated <strong>in</strong> the surface of<br />

the res<strong>in</strong> composite matrix by replication. The orig<strong>in</strong>al<br />

(“master”) structures are made by photolithography, <strong>in</strong> the<br />

case of microstructures (Figure 1), and bead lithography for<br />

the nanostructures (Figure 2). In a first stage, the two types of<br />

structures will be tested separately for their effect on cultured<br />

bone cell l<strong>in</strong>es. Previous studies on dental implants have<br />

shown that multi-length scale topographies give the best bone<br />

60<br />

<strong>in</strong>tegration. So, comb<strong>in</strong>ations of the <strong>in</strong>dividual structures that<br />

give the best results will also be tested.<br />

Figure 2: Pillar structures <strong>in</strong> a silicon master<br />

<strong>CSEM</strong> is also develop<strong>in</strong>g methods to determ<strong>in</strong>e the reaction<br />

of bone cells to structured surfaces. In addition to previously<br />

reported new methods to directly measure cell adhesion are<br />

be<strong>in</strong>g <strong>in</strong>vestigated. One of the most promis<strong>in</strong>g of these<br />

methods uses a specially adapted atomic force microscope<br />

(AFM) to measure the force necessary to pull <strong>in</strong>dividual cells<br />

from the surface (see Figure 3).<br />

Figure 3: Direct measurement of cell adhesion: a) A cell attached to<br />

an AFM cantilever is brought towards the surface. b) The cell<br />

contacts the surface. c) The cell is pulled away from the surface. The<br />

deflection of the cantilever is measured to determ<strong>in</strong>e the force<br />

applied to the cell. d) The cell is released from the surface.<br />

Initial results with this technique are promis<strong>in</strong>g, and it is hoped<br />

that it will give new <strong>in</strong>sights <strong>in</strong>to the <strong>in</strong>fluence of surface<br />

modification on the <strong>in</strong>teractions between bone cells and<br />

surfaces.<br />

This work was partially f<strong>in</strong>anced by the European Commission<br />

<strong>in</strong> the context of the Project Newbone (NMP3-CT-<strong>2007</strong>-<br />

026279). <strong>CSEM</strong> thanks them for their support.