research activities in 2007 - CSEM

research activities in 2007 - CSEM

research activities in 2007 - CSEM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Sol-Gel based Nanoporous Layers as New Sens<strong>in</strong>g Interfaces<br />

E. Scolan, V. Monnier, R. Steiger, R. Pug<strong>in</strong><br />

Sol-gel processes are very versatile and well-suited for the deposition of layers with controlled homogeneity, thickness, porosity and associated<br />

surface structures. The high surface area generated by the porosity and the pore size and shape are used to improve the sensitivity and the<br />

selectivity of specifically designed sensors, respectively.<br />

Nanotechnology creates functional materials, devices, and<br />

systems by controll<strong>in</strong>g matter at the atomic and molecular<br />

scales, thus result<strong>in</strong>g <strong>in</strong> novel exploitable properties and<br />

phenomena. The control at the nanometer scale is especially<br />

important <strong>in</strong> the sensor world s<strong>in</strong>ce most chemical and<br />

biological sensors, as well as many physical sensors, depend<br />

on <strong>in</strong>teractions occurr<strong>in</strong>g at these scales.<br />

Sol-gel processes [1] can be broadly def<strong>in</strong>ed as the preparation<br />

of designed metal oxide materials at the nanometer scale<br />

(<strong>in</strong>clud<strong>in</strong>g fibers, powders/particles, shaped/molded bulks,<br />

(th<strong>in</strong>) films). The gentle wet chemistry route to ceramics has<br />

many advantages. One of the most technologically important<br />

aspects of sol-gel process<strong>in</strong>g is that, prior to gelation, sols are<br />

ideal for prepar<strong>in</strong>g th<strong>in</strong> films, us<strong>in</strong>g common coat<strong>in</strong>g<br />

processes such as dipp<strong>in</strong>g, sp<strong>in</strong>n<strong>in</strong>g, spray<strong>in</strong>g or spread<strong>in</strong>g<br />

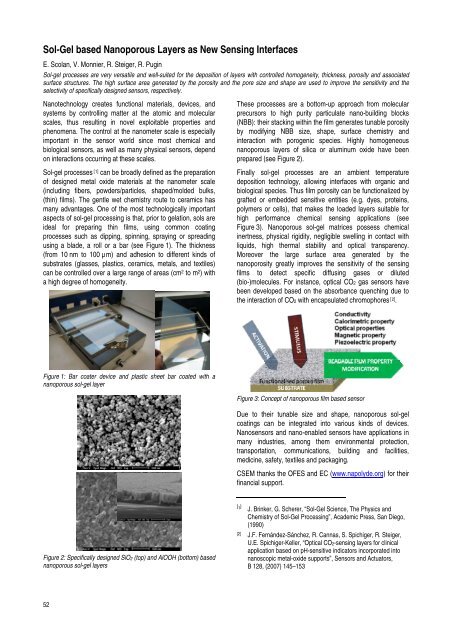

us<strong>in</strong>g a blade, a roll or a bar (see Figure 1). The thickness<br />

(from 10 nm to 100 µm) and adhesion to different k<strong>in</strong>ds of<br />

substrates (glasses, plastics, ceramics, metals, and textiles)<br />

can be controlled over a large range of areas (cm2 to m2 ) with<br />

a high degree of homogeneity.<br />

Figure 1: Bar coater device and plastic sheet bar coated with a<br />

nanoporous sol-gel layer<br />

Figure 2: Specifically designed SiO2 (top) and AlOOH (bottom) based<br />

nanoporous sol-gel layers<br />

52<br />

These processes are a bottom-up approach from molecular<br />

precursors to high purity particulate nano-build<strong>in</strong>g blocks<br />

(NBB): their stack<strong>in</strong>g with<strong>in</strong> the film generates tunable porosity<br />

by modify<strong>in</strong>g NBB size, shape, surface chemistry and<br />

<strong>in</strong>teraction with porogenic species. Highly homogeneous<br />

nanoporous layers of silica or alum<strong>in</strong>um oxide have been<br />

prepared (see Figure 2).<br />

F<strong>in</strong>ally sol-gel processes are an ambient temperature<br />

deposition technology, allow<strong>in</strong>g <strong>in</strong>terfaces with organic and<br />

biological species. Thus film porosity can be functionalized by<br />

grafted or embedded sensitive entities (e.g. dyes, prote<strong>in</strong>s,<br />

polymers or cells), that makes the loaded layers suitable for<br />

high performance chemical sens<strong>in</strong>g applications (see<br />

Figure 3). Nanoporous sol-gel matrices possess chemical<br />

<strong>in</strong>ertness, physical rigidity, negligible swell<strong>in</strong>g <strong>in</strong> contact with<br />

liquids, high thermal stability and optical transparency.<br />

Moreover the large surface area generated by the<br />

nanoporosity greatly improves the sensitivity of the sens<strong>in</strong>g<br />

films to detect specific diffus<strong>in</strong>g gases or diluted<br />

(bio-)molecules. For <strong>in</strong>stance, optical CO2 gas sensors have<br />

been developed based on the absorbance quench<strong>in</strong>g due to<br />

the <strong>in</strong>teraction of CO2 with encapsulated chromophores [2] .<br />

Figure 3: Concept of nanoporous film based sensor<br />

Due to their tunable size and shape, nanoporous sol-gel<br />

coat<strong>in</strong>gs can be <strong>in</strong>tegrated <strong>in</strong>to various k<strong>in</strong>ds of devices.<br />

Nanosensors and nano-enabled sensors have applications <strong>in</strong><br />

many <strong>in</strong>dustries, among them environmental protection,<br />

transportation, communications, build<strong>in</strong>g and facilities,<br />

medic<strong>in</strong>e, safety, textiles and packag<strong>in</strong>g.<br />

<strong>CSEM</strong> thanks the OFES and EC (www.napolyde.org) for their<br />

f<strong>in</strong>ancial support.<br />

[ 1 ] J. Br<strong>in</strong>ker, G. Scherer, “Sol-Gel Science, The Physics and<br />

Chemistry of Sol-Gel Process<strong>in</strong>g”, Academic Press, San Diego,<br />

(1990)<br />

[2] J.F. Fernández-Sánchez, R. Cannas, S. Spichiger, R. Steiger,<br />

U.E. Spichiger-Keller, “Optical CO2-sens<strong>in</strong>g layers for cl<strong>in</strong>ical<br />

application based on pH-sensitive <strong>in</strong>dicators <strong>in</strong>corporated <strong>in</strong>to<br />

nanoscopic metal-oxide supports”, Sensors and Actuators,<br />

B 128, (<strong>2007</strong>) 145–153