- Page 1:

A Design Guide for Implementers and

- Page 4 and 5:

LID Manual for Michigan Page ii

- Page 6 and 7:

Shawn Keenan, City of Auburn Hills

- Page 8 and 9:

Appendix G: Stormwater Management P

- Page 10 and 11:

Figure 7.18 Filter with infiltratio

- Page 12 and 13:

Table 7.9 Definitions of Wetland Ve

- Page 14 and 15:

How this manual is organized This m

- Page 16 and 17:

discuss a new development. The staf

- Page 18 and 19:

In a natural woodland or meadow in

- Page 20 and 21:

Almost all components of the urban

- Page 22 and 23:

Benefits of implementing LID Implem

- Page 24 and 25:

Table 2.2 Summary of Cost Compariso

- Page 26 and 27:

Getting started with LID LID can be

- Page 28 and 29:

Precipitation also varies slightly

- Page 30 and 31:

Figure 3.4 Soil Freezing in Lower M

- Page 32 and 33:

Figure 3.6 Michigan Surficial Geolo

- Page 34 and 35:

Most soils in Michigan are classifi

- Page 36 and 37:

Table 3.3 Representative Cation Exc

- Page 38 and 39:

There is currently no single broadl

- Page 40 and 41:

Wellhead protection areas/ public w

- Page 42 and 43:

Table 3.4 Michigan Rivers and Strea

- Page 44 and 45:

References * Bailey, R.M and G.R. S

- Page 46 and 47:

LID Manual for Michigan - Chapter 3

- Page 48 and 49:

Following are sample goals and poli

- Page 50 and 51:

Develop regulations that encourage/

- Page 52 and 53:

Construction activity • Minimize

- Page 54 and 55:

Street sweeping in Bloomfield Towns

- Page 56 and 57:

Resistance from internal sources an

- Page 58 and 59:

Site constraints that may pose chal

- Page 60 and 61:

Entity Stormwater Jurisdiction Coun

- Page 62 and 63:

Step 1: Property acquisition and us

- Page 64 and 65:

can be incorporated into the develo

- Page 66 and 67:

Step 3: Integrate municipal, county

- Page 68 and 69:

LID Manual for Michigan - Chapter 5

- Page 70 and 71:

BMP Selection Process This chapter

- Page 72 and 73:

Case Study: Title The second page o

- Page 74 and 75:

Case Study: Pokagon Band of Potawat

- Page 76 and 77:

Figure 6.2 Conventional development

- Page 78 and 79:

Designer/Reviewer Checklist for Clu

- Page 80 and 81:

LID Manual for Michigan - Chapter 6

- Page 82 and 83:

Case Study: Minimizing soil compact

- Page 84 and 85:

4. Topsoil stockpiling and storage

- Page 86 and 87:

References Hanks, D. and Lewandowsk

- Page 88 and 89:

Case Study: Longmeadow Development

- Page 90 and 91:

Applications Minimizing the total d

- Page 92 and 93:

Criteria to Receive Credits for Min

- Page 94 and 95:

LID Manual for Michigan - Chapter 6

- Page 96 and 97:

Case Study: Marywood Health Center

- Page 98 and 99:

Design Considerations 1. Identify n

- Page 100 and 101:

References Center for Watershed Pro

- Page 102 and 103:

Case Study: Macomb County Public Wo

- Page 104 and 105:

Zone 3: Also termed the “outer zo

- Page 106 and 107:

• Limit clearing and grading of f

- Page 108 and 109:

LID Manual for Michigan - Chapter 6

- Page 110 and 111:

Case Study: Western Michigan Univer

- Page 112 and 113:

Protection of sensitive areas in re

- Page 114 and 115:

then weightings of potential develo

- Page 116 and 117:

Floodplains • Design the project

- Page 118 and 119:

References Arendt, Randall G. Growi

- Page 120 and 121:

Case Study: Willard Beach Implement

- Page 122 and 123:

Table 6.2 Narrow residential street

- Page 124 and 125:

Parking Parking lots often comprise

- Page 126 and 127:

Designer/Reviewer Checklist for Red

- Page 128 and 129:

Case Study: Saugatuck Center for th

- Page 130 and 131:

In addition to directing runoff to

- Page 132 and 133:

Designer/Reviewer Checklist for Dis

- Page 134 and 135:

Runoff Volume/ Infiltration Runoff

- Page 136 and 137:

Figure 7.1 Structural BMP Selection

- Page 138 and 139:

In general, the techniques describe

- Page 140 and 141:

Table 7.3 Additional BMP considerat

- Page 142 and 143:

Maintenance Provides guidance on re

- Page 144 and 145:

Case Study: Grayling Stormwater Pro

- Page 146 and 147:

Figure 7.5 illustrates a schematic

- Page 148 and 149:

Flow inlet: Curbs and curb cuts Cur

- Page 150 and 151:

Roads and highways Figure 7.13 show

- Page 152 and 153:

Design Considerations Bioretention

- Page 154 and 155:

7. Planting periods will vary but,

- Page 156 and 157:

Construction Guidelines The followi

- Page 158 and 159:

Designer/Reviewer Checklist for Rai

- Page 160 and 161:

Case Study: Stormwater Capture with

- Page 162 and 163:

Ford Rouge Plant cistern Vertical s

- Page 164 and 165:

Design Considerations Design and in

- Page 166 and 167:

the tank can accommodate.) (www.sta

- Page 168 and 169:

References “Black Vertical Storag

- Page 170 and 171:

Case Study: Constructed Linear Sand

- Page 172 and 173:

Surface non-vegetated filter A surf

- Page 174 and 175:

Large subsurface filter Large Subsu

- Page 176 and 177:

would modestly increase constructio

- Page 178 and 179:

During inspection the following con

- Page 180 and 181:

References Atlanta Regional Commiss

- Page 182 and 183:

Site Factors Type Basin Bottom Rela

- Page 184 and 185:

LID Manual for Michigan - Chapter 7

- Page 186 and 187:

Variations For this manual, detenti

- Page 188 and 189:

Precast concrete vault Source: Amer

- Page 190 and 191:

surface into the pond to a maximum

- Page 192 and 193:

sink for pollutants and generally h

- Page 194 and 195:

The presettlement and post-developm

- Page 196 and 197:

wet pond and constructed wetland op

- Page 198 and 199:

ackfilling operation should driven

- Page 200 and 201:

Designer/Reviewer Checklist for Dry

- Page 202 and 203:

Designer/Reviewer Checklist for Con

- Page 204 and 205:

References AMEC Earth and Environme

- Page 206 and 207:

Key Design Features • Depth to wa

- Page 208 and 209:

Case Study: Saugatuck Center for th

- Page 210 and 211:

Infiltration basins, subsurface inf

- Page 212 and 213:

Figure 7.24 Cross-section of dry we

- Page 214 and 215: • The soil mantle should be prese

- Page 216 and 217: Additional design considerations fo

- Page 218 and 219: • Though roofs are generally not

- Page 220 and 221: Subsurface infiltration bed Source:

- Page 222 and 223: Stormwater Functions and Calculatio

- Page 224 and 225: • Protect the infiltration area f

- Page 226 and 227: Additional Construction Guidelines

- Page 228 and 229: Designer/Reviewer Checklist for Inf

- Page 230 and 231: References AMEC Earth and Environme

- Page 232 and 233: LID Manual for Michigan - Chapter 7

- Page 234 and 235: Case Study: Washtenaw County West S

- Page 236 and 237: Design Considerations Level spreade

- Page 238 and 239: 3. Inspect the filter strip and the

- Page 240 and 241: References Hathaway, Jon and Hunt,

- Page 242 and 243: Case Study: Black River Heritage Tr

- Page 244 and 245: Figure 7.31 Native meadow species c

- Page 246 and 247: Applications • Residential - Nati

- Page 248 and 249: 5. Amend soil: In those sites where

- Page 250 and 251: Water quality improvement Landscape

- Page 252 and 253: References Arendt, R. Growing Green

- Page 254 and 255: Case Study: Grand Valley State Univ

- Page 256 and 257: Staging, construction practices, an

- Page 258 and 259: Reinforced turf/gravel Reinforced t

- Page 260 and 261: 4. Pervious pavement and infiltrati

- Page 262 and 263: 12. Proper pervious pavement applic

- Page 266 and 267: Repairs • Surface should never be

- Page 268 and 269: References Adams, Michele. “Porou

- Page 270 and 271: Case Study: Michigan Avenue Streets

- Page 272 and 273: Native vegetation should be used in

- Page 274 and 275: Design Considerations • Suggested

- Page 276 and 277: oxes, etc. should be installed in a

- Page 278 and 279: References Stormwater Management Gu

- Page 280 and 281: Case Study: Nankin Mills Interpreti

- Page 282 and 283: Figure 7.45 Schematic of a three-zo

- Page 284 and 285: 3. Analyze site’s vegetative feat

- Page 286 and 287: Black River Heritage Trail and Wate

- Page 288 and 289: Table 7.14 Tree spacing per acre Sp

- Page 290 and 291: 4. Stable debris As Zone 1 reaches

- Page 292 and 293: References Alliance for the Chesape

- Page 294 and 295: Case Study: Ann Arbor District Libr

- Page 296 and 297: • Major compaction - Deep compact

- Page 298 and 299: e. Add six inches compost or other

- Page 300 and 301: References “Achieving the Post-Co

- Page 302 and 303: Case Study: Wayne County, MI Ford R

- Page 304 and 305: slope needs to be determined. This

- Page 306 and 307: Figure 7.52 Sandy soils with HSG Gr

- Page 308 and 309: Figure 7.56 Clay Loam, Silty Clay o

- Page 310 and 311: • Guidance information, usually i

- Page 312 and 313: LID Manual for Michigan - Chapter 7

- Page 314 and 315:

Case Study: City of Battle Creek Ci

- Page 316 and 317:

Table 7.16 Vegetated roof types Ext

- Page 318 and 319:

Dual media assemblies Dual media (F

- Page 320 and 321:

Over a period of time roots can dam

- Page 322 and 323:

Technical requirements Root resista

- Page 324 and 325:

Stormwater Functions and Calculatio

- Page 326 and 327:

Designer/Reviewer Checklist for Veg

- Page 328 and 329:

Case Study: Meadowlake Farms Bioswa

- Page 330 and 331:

lower flows (two-year storm) to dra

- Page 332 and 333:

Stone check dams Source: Road Commi

- Page 334 and 335:

Table 7.18 Permanent stabilization

- Page 336 and 337:

Peak rate mitigation Vegetated swal

- Page 338 and 339:

Designer/Reviewer Checklist for Veg

- Page 340 and 341:

LID Manual for Michigan - Chapter 7

- Page 342 and 343:

Case Study: LaVista Storm Drain Pro

- Page 344 and 345:

Basket type inserts Basket type ins

- Page 346 and 347:

Maintenance is crucial to the effec

- Page 348 and 349:

Roadway design, construction, and m

- Page 350 and 351:

• Vegetated systems such as grass

- Page 352 and 353:

Of the options explored, the study

- Page 354 and 355:

Figure 8.3 Tree planting detail Sou

- Page 356 and 357:

Opportunities for MPOs Metropolitan

- Page 358 and 359:

Construction on the project began i

- Page 360 and 361:

The following are examples of imple

- Page 362 and 363:

Horizontal grates can be added to a

- Page 364 and 365:

East Hills Center City of Grand Rap

- Page 366 and 367:

Implementing LID in High Risk Areas

- Page 368 and 369:

References AASHTO Center for Enviro

- Page 370 and 371:

LID Design Criteria Defining the hy

- Page 372 and 373:

Flood control Flood control is base

- Page 374 and 375:

Table 9.1 90 Percent Nonexceedance

- Page 376 and 377:

Initial abstraction (I a ) includes

- Page 378 and 379:

The Curve Number Method is less acc

- Page 380 and 381:

I = the average rainfall intensity

- Page 382 and 383:

Table 9.4 Rainfall Events of 24-Hou

- Page 384 and 385:

• Proceed to Flow Chart B, Peak R

- Page 386 and 387:

FLOW CHART A Stormwater Calculation

- Page 388 and 389:

Excessively drained soils may requi

- Page 390 and 391:

Worksheet 2. Sensitive Natural Reso

- Page 392 and 393:

WORKSHEET 4. Calculations for Volum

- Page 394 and 395:

WORKSHEET 6. SMALL SITE / SMALL IMP

- Page 396 and 397:

WORKSHEET 8. WATER QUALITY WORKSHEE

- Page 398 and 399:

Reese, S. and J. Lee. “Summary of

- Page 400 and 401:

ing Department. Most maintenance co

- Page 402 and 403:

The Hydrotech Garden Roof Assembly

- Page 404 and 405:

Bioswales provide infiltration of s

- Page 406 and 407:

The Ingham County Drain Commissione

- Page 408 and 409:

Constructed wetland The lowest port

- Page 410 and 411:

LID Manual for Michigan - Chapter 1

- Page 412 and 413:

LID Manual for Michigan - Appendix

- Page 414 and 415:

Check dam Cistern Clustering Combin

- Page 416 and 417:

H:V Horizontal to vertical ratio. H

- Page 418 and 419:

Planter box Pervious pavement Phase

- Page 420 and 421:

Total phosphorous (TP) The total am

- Page 422 and 423:

Ecoregion recommendations are also

- Page 424 and 425:

Zone A Planting Zone = two-to-four

- Page 426 and 427:

Zone C Planting Zone = zero-to-two

- Page 428 and 429:

Representative Zone C Species Cardi

- Page 430 and 431:

Botanical Name Common Name Height C

- Page 432 and 433:

Zone E Planting Zone = four-to-18 i

- Page 434 and 435:

Representative Zone E Species Tall

- Page 436 and 437:

Botanical Name Common Name Height C

- Page 438 and 439:

Zone G Planter Box Plantings Althou

- Page 440 and 441:

Zone H Vegetated Roof Plantings Res

- Page 442 and 443:

LID Manual for Michigan - Appendix

- Page 444 and 445:

Pervious Berms (Vegetated Filter St

- Page 446 and 447:

Vegetated roofs Some key components

- Page 448 and 449:

LID Manual for Michigan - Appendix

- Page 450 and 451:

Step 1. Background evaluation Prior

- Page 452 and 453:

Methodology for double-ring infiltr

- Page 454 and 455:

Step 4. Use design considerations p

- Page 456 and 457:

LID Manual for Michigan - Appendix

- Page 458 and 459:

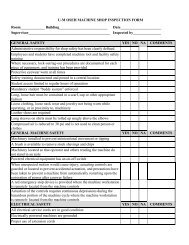

Detention BMP Inspection Checklist*

- Page 460 and 461:

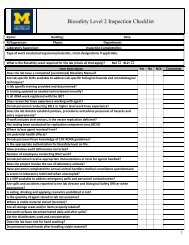

Infiltration BMPs Inspection Checkl

- Page 462 and 463:

Bioretention Inspection Checklist*

- Page 464 and 465:

Bioswale, Filter Strip Inspection C

- Page 466 and 467:

LID Manual for Michigan - Appendix

- Page 468 and 469:

6. The [Community] or its designee

- Page 470 and 471:

STATE OF MICHIGAN ) ) ss. COUNTY OF

- Page 472 and 473:

Exhibit B - Location Map (Sample) S

- Page 474 and 475:

LID Manual for Michigan - Appendix

- Page 476 and 477:

LID Manual for Michigan - Appendix

- Page 478 and 479:

LID Manual for Michigan - Appendix

- Page 480 and 481:

LID Manual for Michigan - Appendix

- Page 482 and 483:

LID Manual for Michigan - Appendix

- Page 484 and 485:

LID Manual for Michigan - Appendix

- Page 486 and 487:

LID Manual for Michigan - Appendix

- Page 488 and 489:

LID Manual for Michigan - Appendix

- Page 490 and 491:

• Stormwater runoff, soil erosion

- Page 492 and 493:

Retention. A holding system for sto

- Page 494 and 495:

ARTICLE IV. STORMWATER PLAN REQUIRE

- Page 496 and 497:

The particular facilities and measu

- Page 498 and 499:

10. Rainfall Frequency Atlas of the

- Page 500 and 501:

Table H.2 Pre-Treatment Options for

- Page 502 and 503:

f. Complete development agreements

- Page 504 and 505:

must be submitted to the Michigan D

- Page 506 and 507:

C. Construction Plans shall be revi

- Page 508 and 509:

fine for each day. The rights and r

- Page 512:

Southeast Michigan Council of Gover