A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

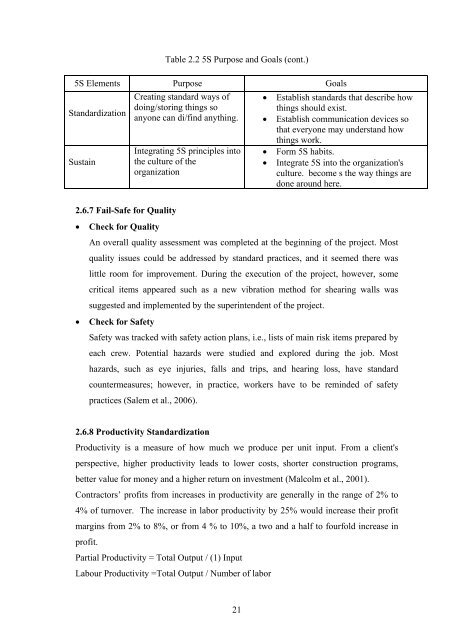

Table 2.2 5S Purpose and Goals (cont.)<br />

5S Elements Purpose Goals<br />

Standardization<br />

Susta<strong>in</strong><br />

2.6.7 Fail-Safe for Quality<br />

• Check for Quality<br />

Creat<strong>in</strong>g standard ways <strong>of</strong><br />

do<strong>in</strong>g/stor<strong>in</strong>g th<strong>in</strong>gs so<br />

anyone can di/f<strong>in</strong>d anyth<strong>in</strong>g.<br />

Integrat<strong>in</strong>g 5S pr<strong>in</strong>ciples <strong>in</strong>to<br />

the culture <strong>of</strong> the<br />

organization<br />

• Establish standards that describe how<br />

th<strong>in</strong>gs should exist.<br />

• Establish communication devices so<br />

that everyone may understand how<br />

th<strong>in</strong>gs work.<br />

• Form 5S habits.<br />

• Integrate 5S <strong>in</strong>to the organization's<br />

culture. become s the way th<strong>in</strong>gs are<br />

done around here.<br />

An overall quality assessment was completed at the beg<strong>in</strong>n<strong>in</strong>g <strong>of</strong> the project. Most<br />

quality issues could be addressed by standard practices, and it seemed there was<br />

little room for improvement. Dur<strong>in</strong>g the execution <strong>of</strong> the project, however, some<br />

critical items appeared such as a new vibration method for shear<strong>in</strong>g walls was<br />

suggested and implemented by the super<strong>in</strong>tendent <strong>of</strong> the project.<br />

• Check for Safety<br />

Safety was tracked with safety action plans, i.e., lists <strong>of</strong> ma<strong>in</strong> risk items prepared by<br />

each crew. Potential hazards were studied and explored dur<strong>in</strong>g the job. Most<br />

hazards, such as eye <strong>in</strong>juries, falls and trips, and hear<strong>in</strong>g loss, have standard<br />

countermeasures; however, <strong>in</strong> practice, workers have to be rem<strong>in</strong>ded <strong>of</strong> safety<br />

practices (Salem et al., 2006).<br />

2.6.8 Productivity Standardization<br />

Productivity is a measure <strong>of</strong> how much we produce per unit <strong>in</strong>put. From a client's<br />

perspective, higher productivity leads to lower costs, shorter construction programs,<br />

better value for money and a higher return on <strong>in</strong>vestment (Malcolm et al., 2001).<br />

Contractors’ pr<strong>of</strong>its from <strong>in</strong>creases <strong>in</strong> productivity are generally <strong>in</strong> the range <strong>of</strong> 2% to<br />

4% <strong>of</strong> turnover. The <strong>in</strong>crease <strong>in</strong> labor productivity by 25% would <strong>in</strong>crease their pr<strong>of</strong>it<br />

marg<strong>in</strong>s from 2% to 8%, or from 4 % to 10%, a two and a half to fourfold <strong>in</strong>crease <strong>in</strong><br />

pr<strong>of</strong>it.<br />

Partial Productivity = Total Output / (1) Input<br />

Labour Productivity =Total Output / Number <strong>of</strong> labor<br />

21