A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ma<strong>in</strong><br />

Activity<br />

Build<strong>in</strong>g work<br />

3.2.2 Secondary Sources<br />

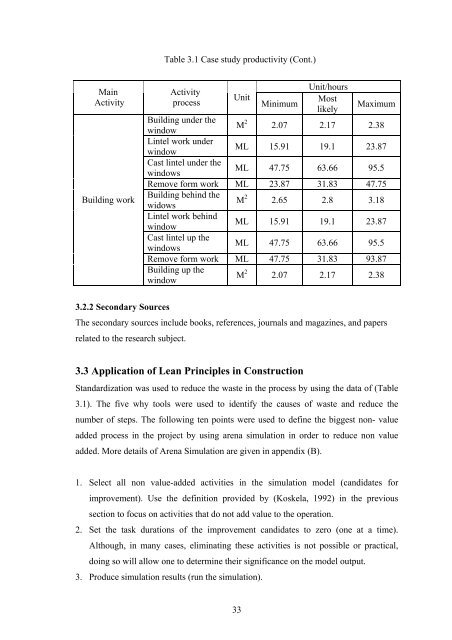

Table 3.1 Case study productivity (Cont.)<br />

Activity<br />

process<br />

Build<strong>in</strong>g under the<br />

w<strong>in</strong>dow<br />

M 2<br />

L<strong>in</strong>tel work under<br />

w<strong>in</strong>dow<br />

ML<br />

Cast l<strong>in</strong>tel under the<br />

w<strong>in</strong>dows<br />

ML<br />

Remove form work ML<br />

Build<strong>in</strong>g beh<strong>in</strong>d the<br />

widows<br />

M 2<br />

L<strong>in</strong>tel work beh<strong>in</strong>d<br />

w<strong>in</strong>dow<br />

ML<br />

Cast l<strong>in</strong>tel up the<br />

w<strong>in</strong>dows<br />

ML<br />

Remove form work ML<br />

Build<strong>in</strong>g up the<br />

w<strong>in</strong>dow<br />

M 2<br />

Unit M<strong>in</strong>imum<br />

Unit/hours<br />

Most<br />

likely<br />

Maximum<br />

2.07 2.17 2.38<br />

15.91 19.1 23.87<br />

47.75 63.66 95.5<br />

23.87 31.83 47.75<br />

2.65 2.8 3.18<br />

15.91 19.1 23.87<br />

47.75 63.66 95.5<br />

47.75 31.83 93.87<br />

2.07 2.17 2.38<br />

The secondary sources <strong>in</strong>clude books, references, journals and magaz<strong>in</strong>es, and papers<br />

related to the research subject.<br />

3.3 Application <strong>of</strong> <strong>Lean</strong> Pr<strong>in</strong>ciples <strong>in</strong> <strong>Construction</strong><br />

Standardization was used to reduce the waste <strong>in</strong> the process by us<strong>in</strong>g the data <strong>of</strong> (Table<br />

3.1). The five why tools were used to identify the causes <strong>of</strong> waste and reduce the<br />

number <strong>of</strong> steps. The follow<strong>in</strong>g ten po<strong>in</strong>ts were used to def<strong>in</strong>e the biggest non- value<br />

added process <strong>in</strong> the project by us<strong>in</strong>g arena simulation <strong>in</strong> order to reduce non value<br />

added. More details <strong>of</strong> Arena Simulation are given <strong>in</strong> appendix (B).<br />

1. Select all non value-added activities <strong>in</strong> the simulation model (candidates for<br />

improvement). Use the def<strong>in</strong>ition provided by (Koskela, 1992) <strong>in</strong> the previous<br />

section to focus on activities that do not add value to the operation.<br />

2. Set the task durations <strong>of</strong> the improvement candidates to zero (one at a time).<br />

Although, <strong>in</strong> many cases, elim<strong>in</strong>at<strong>in</strong>g these activities is not possible or practical,<br />

do<strong>in</strong>g so will allow one to determ<strong>in</strong>e their significance on the model output.<br />

3. Produce simulation results (run the simulation).<br />

33