A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.5 Remove or Reduce the Influence <strong>of</strong> Waste as it is Observed<br />

Simulation has been used <strong>in</strong> each activity to measure the duration and number <strong>of</strong> steps.<br />

Productivity data <strong>in</strong> Table (3.1) was used <strong>in</strong> the simulation model. Results are shown on<br />

Table (4.17). The full simulation results are shown <strong>in</strong> appendix (C).<br />

The results that were reached from mobilization and pla<strong>in</strong> concrete are expla<strong>in</strong>ed as<br />

follows ( the other activities use the same methodology).<br />

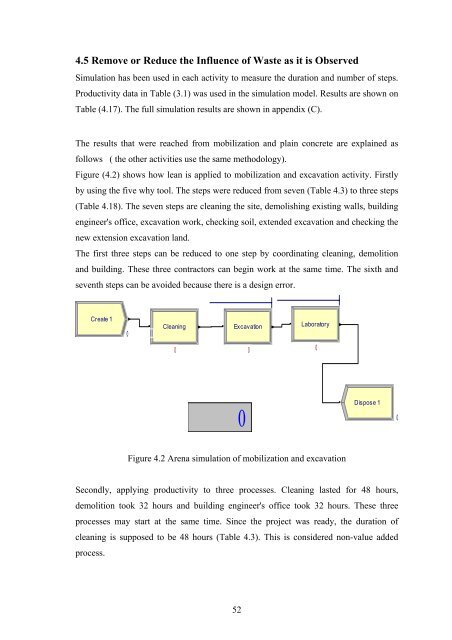

Figure (4.2) shows how lean is applied to mobilization and excavation activity. Firstly<br />

by us<strong>in</strong>g the five why tool. The steps were reduced from seven (Table 4.3) to three steps<br />

(Table 4.18). The seven steps are clean<strong>in</strong>g the site, demolish<strong>in</strong>g exist<strong>in</strong>g walls, build<strong>in</strong>g<br />

eng<strong>in</strong>eer's <strong>of</strong>fice, excavation work, check<strong>in</strong>g soil, extended excavation and check<strong>in</strong>g the<br />

new extension excavation land.<br />

The first three steps can be reduced to one step by coord<strong>in</strong>at<strong>in</strong>g clean<strong>in</strong>g, demolition<br />

and build<strong>in</strong>g. These three contractors can beg<strong>in</strong> work at the same time. The sixth and<br />

seventh steps can be avoided because there is a design error.<br />

Create 1<br />

0<br />

Clean<strong>in</strong>g Ex cav ation Laboratory<br />

0 0 0<br />

Dispose 1<br />

0<br />

0<br />

Figure 4.2 Arena simulation <strong>of</strong> mobilization and excavation<br />

Secondly, apply<strong>in</strong>g productivity to three processes. Clean<strong>in</strong>g lasted for 48 hours,<br />

demolition took 32 hours and build<strong>in</strong>g eng<strong>in</strong>eer's <strong>of</strong>fice took 32 hours. These three<br />

processes may start at the same time. S<strong>in</strong>ce the project was ready, the duration <strong>of</strong><br />

clean<strong>in</strong>g is supposed to be 48 hours (Table 4.3). This is considered non-value added<br />

process.<br />

52