A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

A Study of Lean Construction Practices in Gaza Strip

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

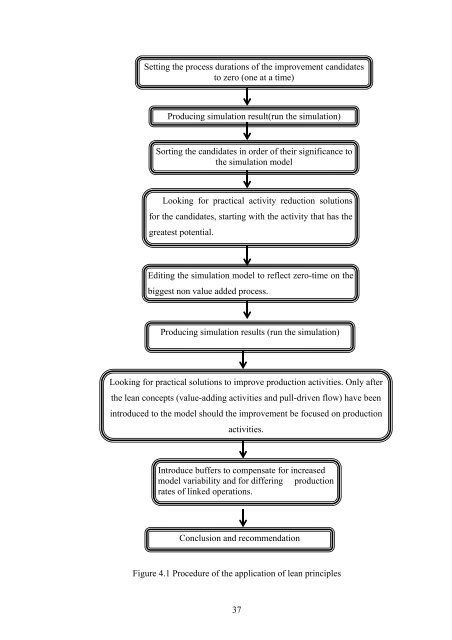

Sett<strong>in</strong>g the process durations <strong>of</strong> the improvement candidates<br />

to zero (one at a time)<br />

Produc<strong>in</strong>g simulation result(run the simulation)<br />

Sort<strong>in</strong>g the candidates <strong>in</strong> order <strong>of</strong> their significance to<br />

the simulation model<br />

Look<strong>in</strong>g for practical activity reduction solutions<br />

for the candidates, start<strong>in</strong>g with the activity that has the<br />

greatest potential.<br />

Edit<strong>in</strong>g the simulation model to reflect zero-time on the<br />

biggest non value added process.<br />

Produc<strong>in</strong>g simulation results (run the simulation)<br />

Look<strong>in</strong>g for practical solutions to improve production activities. Only after<br />

the lean concepts (value-add<strong>in</strong>g activities and pull-driven flow) have been<br />

<strong>in</strong>troduced to the model should the improvement be focused on production<br />

activities.<br />

Introduce buffers to compensate for <strong>in</strong>creased<br />

model variability and for differ<strong>in</strong>g production<br />

rates <strong>of</strong> l<strong>in</strong>ked operations.<br />

Conclusion and recommendation<br />

Figure 4.1 Procedure <strong>of</strong> the application <strong>of</strong> lean pr<strong>in</strong>ciples<br />

37