chapter 3 rigid pavement - DOT On-Line Publications - Department ...

chapter 3 rigid pavement - DOT On-Line Publications - Department ...

chapter 3 rigid pavement - DOT On-Line Publications - Department ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

?%‘.4 TECHWIC.4L ADVISORY T 3040.30<br />

\iovernber 30, 1990<br />

(5)<br />

7. DPANSION JOINTS<br />

-4 L<br />

O.ld<br />

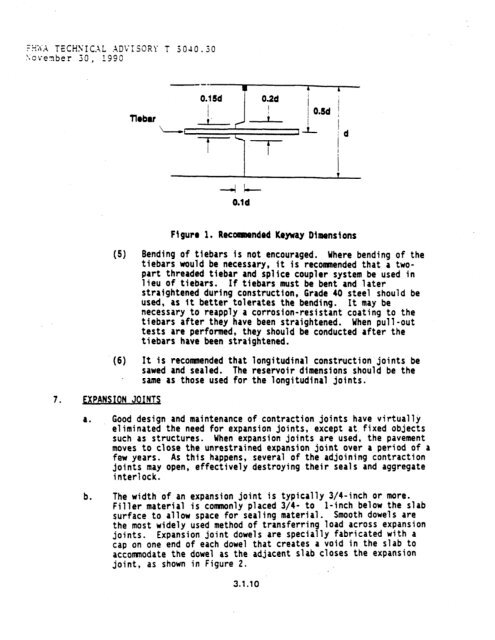

Figure 1. Recoarnended Keyway Dimensions<br />

Bending of tiebars is not encouraged. Where bending of the<br />

tiebars would be necessary, it is reconmnended that a two-<br />

part threaded tiebar and splice coupler system be used in<br />

lieu of tiebars. If tiebars must be bent and later<br />

straightened during construction, Grade 40 steel should be<br />

used, as it better tolerates the bending. It may be<br />

necessary to reapply a corrosion-resistant coating to the<br />

tiebars after they have been straightened. When pull-out<br />

tests are performed, they should be conducted after the<br />

tiebars have been straightened.<br />

(6) It is recommended that longitudinal construction joints be<br />

sawed and sealed. The reservoir dimensions should be the<br />

same as those used for the longitudinal joints.<br />

a. Good design and maintenance of contraction joints have virtually<br />

eliminated the need for expansion joints, except at. fixed objects<br />

such as structures. When expansion joints are used, the <strong>pavement</strong><br />

moves to close the unrestrained expansion joint over a period of a<br />

few years. As this happens, several of the adjoining contraction<br />

joints may open, effectively destroying their seals and aggregate<br />

interlock.<br />

b. The width of an expansion joint is typically 3/4-inch or more.<br />

filler material is commonly placed 3/4- to l-inch below the slab<br />

surface to allow space for sealing material. Smooth dowels are<br />

the most widely used method of transferring load across expansion<br />

joints. Expansion joint dowels are specially fabricated with a<br />

cap on one end of each dowel that creates a void in the slab to<br />

accommodate the dowel as the adjacent slab closes the expansion<br />

joint, as shown in Figure 2.<br />

3.1.10