chapter 3 rigid pavement - DOT On-Line Publications - Department ...

chapter 3 rigid pavement - DOT On-Line Publications - Department ...

chapter 3 rigid pavement - DOT On-Line Publications - Department ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

(7).<br />

(8).<br />

(14).<br />

[ii,‘- .<br />

-_, (17).<br />

(W.<br />

(19).<br />

(20).<br />

(21.)'.<br />

(22).<br />

tsg- .<br />

m l<br />

(2%<br />

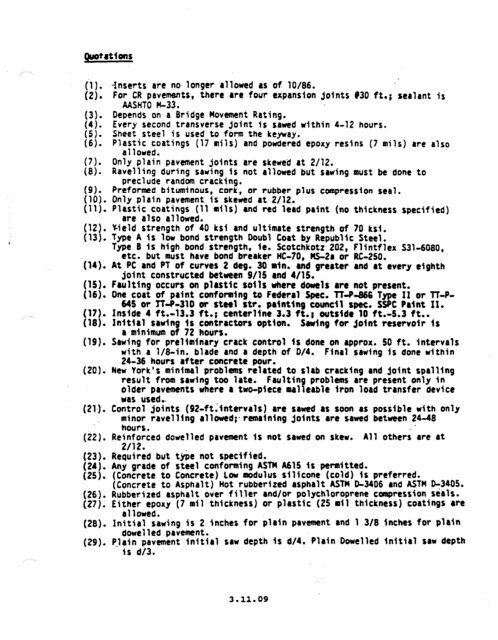

inserts are no longer allowed as of 10/86.<br />

For CR <strong>pavement</strong>s,<br />

AASHTO M-33.<br />

there are four expansion Joints 930 ft.; sealant is<br />

Depends on a Bridge Movanent Rating.<br />

Every second transverse joint is sawed within 4-12 hours.<br />

Sheet steel is used to form the keyway.<br />

Plastic coatings (17 nils) and powdered epoxy resins<br />

allowed.<br />

(7 mils) are also<br />

<strong>On</strong>ly plain <strong>pavement</strong> joints are skewed at Z/12.<br />

Ravclling during sawing is not allowed<br />

preclude random cracking.<br />

but sawing must be done to<br />

Preformed bituminous, cork, or rubber plus compression seal.<br />

<strong>On</strong>ly plain <strong>pavement</strong> is skewed at Z/12.<br />

Plastic coatings (11 mils)<br />

are also allowed.<br />

and red lead paint (no thickness specified)<br />

Yield strength of 40 ksi and ultimate strength of 70 ksi.<br />

Type A is low bond strength Doubl Coat by Republic Steel.<br />

Type B is high bond strength, it.<br />

etc. but must have bond breaker<br />

Scotchkotr 202, Flintflex<br />

HC-70, MS2a or RC-258.<br />

531-6080,<br />

At PC and PT of curves 2 deg. 30 mfn. and Orcater and at every eighth<br />

joint constructed between 9/15 and 4/W.<br />

Faulting occurs on plastic soils where dowels are not present.<br />

<strong>On</strong>e coat of paint conforming to Federal Spec. lT4-866 1 II or n-P-<br />

645 or TT-P-310 or steel str. pahthg councfl tpec. S F C Paint II.<br />

Inside 4 ft.-13.3 ft.8 centerline 3.3 ft.8 outsfde 10 ft.4.3 ft..<br />

Inltlal sawing Ii contractors option. Sawing for joint reservoir Is<br />

a minimum of 72 hours.<br />

Sawing for preliminary crack control Is done on approx. 50 ft. intervals<br />

with a l/8-in. blade and a depth of D/4. Final sawing is done within<br />

24-36 hours after concrete Pour.<br />

New York's minimal problems related to slab cracking and joint spalllng<br />

result from sawing too late. Faulting problems are present only in<br />

older <strong>pavement</strong>s where a two-piece malleable iron load transfer device<br />

was used..<br />

Control joints (92rft;intervals) are sawed as soon as porrlble with only<br />

minor ravelling alloued;~runaining joints are sawed between 2448<br />

hours.<br />

Reinforced dowelled <strong>pavement</strong> is not sawed on skew. All other; are at<br />

2/12.<br />

Required but type not specified.<br />

Any grade of steel conforming ASlU A615 ts permitted.<br />

(Concrete to Concrete) Lou modulus silicone (cold) is preferred.<br />

(Concrete to Asphalt) Hot rubberized asphalt ASm D-3406 and ASTM D-3405.<br />

Rubberized asphalt over filler and/or polychloroprent compression Seals.<br />

Ei::;;w;;oxy (7 mil thickness) or plastic (25 ail thickness) ,coatingS am<br />

]nitial &ng is 2 jnches for plain <strong>pavement</strong> rnd 1 3/B inches for plain<br />

dowelled <strong>pavement</strong>.<br />

Plain <strong>pavement</strong> initial saw depth is d/4. Plain Dowelled Initial SW depth<br />

is d/3.<br />

3.11.09