Code of Practice for the Electricity (Wiring) Regulations - 2009 Edition

Code of Practice for the Electricity (Wiring) Regulations - 2009 Edition

Code of Practice for the Electricity (Wiring) Regulations - 2009 Edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

(b) Where cables run as a span between beams, trusses, etc., rigid<br />

support throughout <strong>the</strong>ir entire length should be used. One <strong>of</strong> <strong>the</strong><br />

fixing methods <strong>of</strong> cables hung under beams is illustrated in Figure<br />

25(2).<br />

(c) Cables crossing an expansion joint should be <strong>for</strong>med into a loop<br />

such that any movement in <strong>the</strong> joint should not stress <strong>the</strong> cables.<br />

(d ) For cables running on surface <strong>of</strong> walls or structures:<br />

(i) buckle clip should only be used to fix cables having an overall<br />

diameter not exceeding 10 mm.<br />

(ii) saddles and cleats may be used if <strong>the</strong> diameter <strong>of</strong> <strong>the</strong> cable<br />

exceeds 10 mm.<br />

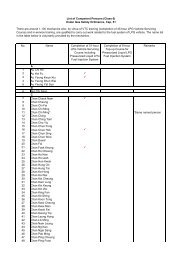

(e) (i) Cable saddles and cable cleats should be secured by fixing<br />

screws and should be provided along <strong>the</strong> entire cable route at<br />

regular intervals. The spacing between adjacent saddles or<br />

cleats should not exceed <strong>the</strong> values given in Table 25(3).<br />

(ii) A saddle or cleat should also be provided at a distance not<br />

exceeding 150 mm from a termination and from both sides <strong>of</strong><br />

a bend.<br />

(f ) Where cables are installed under floors or within false ceilings, <strong>the</strong>y<br />

should normally be supported and fixed throughout <strong>the</strong>ir lengths to<br />

<strong>the</strong> permanent ceiling or floor and provision should be made <strong>for</strong><br />

access to <strong>the</strong> cable <strong>for</strong> inspection and maintenance. Such cables, if<br />

exposed to <strong>the</strong> risk <strong>of</strong> penetration by nails, screws and <strong>the</strong> like,<br />

should be protected by an ear<strong>the</strong>d metallic sheath or enclosed in<br />

ear<strong>the</strong>d steel conduit or trunking securely supported.<br />

(g) Where a wiring system passes through elements <strong>of</strong> building<br />

construction such as floor, walls, ro<strong>of</strong>s, ceilings, partitions or cavity<br />

barriers, <strong>the</strong> openings remaining after passage <strong>of</strong> <strong>the</strong> wiring system<br />

shall be sealed according to <strong>the</strong> fire resistance requirements <strong>of</strong> BS<br />

476:Part 20 or equivalent required <strong>of</strong> <strong>the</strong> element concerned (if any).<br />

(h) The internal bending radii <strong>of</strong> PVC insulated stranded copper cables<br />

should not be less than <strong>the</strong> values given below:<br />

Overall Diameter <strong>of</strong> Cable, D<br />

Not exceeding 10 mm<br />

Exceeding 10 mm but not<br />

exceeding 25 mm<br />

Exceeding 25 mm<br />

Minimum Internal Bending Radius<br />

Non-armoured Armoured<br />

157<br />

3D<br />

4D<br />

6D<br />

6D<br />

6D<br />

6D