Code of Practice for the Electricity (Wiring) Regulations - 2009 Edition

Code of Practice for the Electricity (Wiring) Regulations - 2009 Edition

Code of Practice for the Electricity (Wiring) Regulations - 2009 Edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

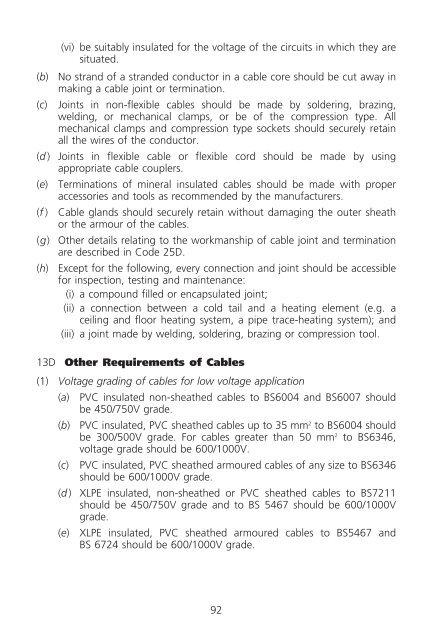

(vi) be suitably insulated <strong>for</strong> <strong>the</strong> voltage <strong>of</strong> <strong>the</strong> circuits in which <strong>the</strong>y are<br />

situated.<br />

(b) No strand <strong>of</strong> a stranded conductor in a cable core should be cut away in<br />

making a cable joint or termination.<br />

(c) Joints in non-flexible cables should be made by soldering, brazing,<br />

welding, or mechanical clamps, or be <strong>of</strong> <strong>the</strong> compression type. All<br />

mechanical clamps and compression type sockets should securely retain<br />

all <strong>the</strong> wires <strong>of</strong> <strong>the</strong> conductor.<br />

(d ) Joints in flexible cable or flexible cord should be made by using<br />

appropriate cable couplers.<br />

(e) Terminations <strong>of</strong> mineral insulated cables should be made with proper<br />

accessories and tools as recommended by <strong>the</strong> manufacturers.<br />

(f ) Cable glands should securely retain without damaging <strong>the</strong> outer sheath<br />

or <strong>the</strong> armour <strong>of</strong> <strong>the</strong> cables.<br />

(g) O<strong>the</strong>r details relating to <strong>the</strong> workmanship <strong>of</strong> cable joint and termination<br />

are described in <strong>Code</strong> 25D.<br />

(h) Except <strong>for</strong> <strong>the</strong> following, every connection and joint should be accessible<br />

<strong>for</strong> inspection, testing and maintenance:<br />

(i) a compound filled or encapsulated joint;<br />

(ii) a connection between a cold tail and a heating element (e.g. a<br />

ceiling and floor heating system, a pipe trace-heating system); and<br />

(iii) a joint made by welding, soldering, brazing or compression tool.<br />

13D O<strong>the</strong>r Requirements <strong>of</strong> Cables<br />

(1) Voltage grading <strong>of</strong> cables <strong>for</strong> low voltage application<br />

(a) PVC insulated non-shea<strong>the</strong>d cables to BS6004 and BS6007 should<br />

be 450/750V grade.<br />

(b) PVC insulated, PVC shea<strong>the</strong>d cables up to 35 mm2 to BS6004 should<br />

be 300/500V grade. For cables greater than 50 mm2 to BS6346,<br />

voltage grade should be 600/1000V.<br />

(c) PVC insulated, PVC shea<strong>the</strong>d armoured cables <strong>of</strong> any size to BS6346<br />

should be 600/1000V grade.<br />

(d ) XLPE insulated, non-shea<strong>the</strong>d or PVC shea<strong>the</strong>d cables to BS7211<br />

should be 450/750V grade and to BS 5467 should be 600/1000V<br />

grade.<br />

(e) XLPE insulated, PVC shea<strong>the</strong>d armoured cables to BS5467 and<br />

BS 6724 should be 600/1000V grade.<br />

92