TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TO</strong> 1-1-<strong>700</strong><br />

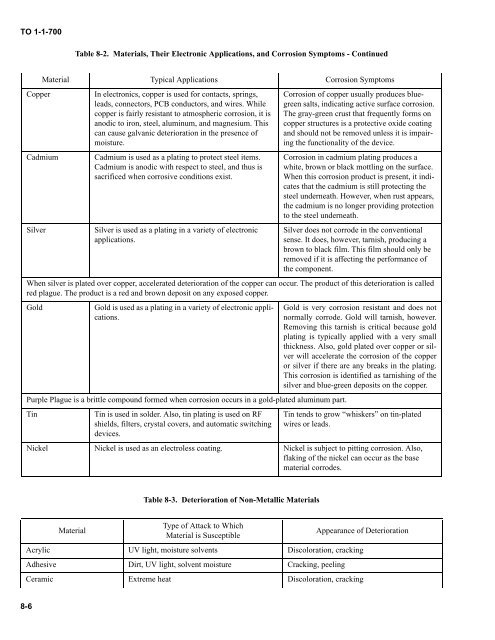

Table 8-2. Materials, Their Electronic Applications, and Corrosion Symptoms - Continued<br />

Copper<br />

Cadmium<br />

Silver<br />

In electronics, copper is used for contacts, springs,<br />

leads, connectors, PCB conductors, and wires. While<br />

copper is fairly resistant to atmospheric corrosion, it is<br />

anodic to iron, steel, aluminum, and magnesium. This<br />

can cause galvanic deterioration in the presence of<br />

moisture.<br />

Cadmium is used as a plating to protect steel items.<br />

Cadmium is anodic with respect to steel, and thus is<br />

sacrificed when corrosive conditions exist.<br />

Silver is used as a plating in a variety of electronic<br />

applications.<br />

Corrosion of copper usually produces bluegreen<br />

salts, indicating active surface corrosion.<br />

The gray-green crust that frequently forms on<br />

copper structures is a protective oxide coating<br />

and should not be removed unless it is impairing<br />

the functionality of the device.<br />

Corrosion in cadmium plating produces a<br />

white, brown or black mottling on the surface.<br />

When this corrosion product is present, it indicates<br />

that the cadmium is still protecting the<br />

steel underneath. However, when rust appears,<br />

the cadmium is no longer providing protection<br />

to the steel underneath.<br />

Silver does not corrode in the conventional<br />

sense. It does, however, tarnish, producing a<br />

brown to black film. This film should only be<br />

removed if it is affecting the performance of<br />

the component.<br />

When silver is plated over copper, accelerated deterioration of the copper can occur. The product of this deterioration is called<br />

red plague. The product is a red and brown deposit on any exposed copper.<br />

Gold<br />

Gold is used as a plating in a variety of electronic applications.<br />

Purple Plague is a brittle compound formed when corrosion occurs in a gold-plated aluminum part.<br />

Tin<br />

Material Typical Applications Corrosion Symptoms<br />

Tin is used in solder. Also, tin plating is used on RF<br />

shields, filters, crystal covers, and automatic switching<br />

devices.<br />

Gold is very corrosion resistant and does not<br />

normally corrode. Gold will tarnish, however.<br />

Removing this tarnish is critical because gold<br />

plating is typically applied with a very small<br />

thickness. Also, gold plated over copper or silver<br />

will accelerate the corrosion of the copper<br />

or silver if there are any breaks in the plating.<br />

This corrosion is identified as tarnishing of the<br />

silver and blue-green deposits on the copper.<br />

Tin tends to grow “whiskers” on tin-plated<br />

wires or leads.<br />

Nickel Nickel is used as an electroless coating. Nickel is subject to pitting corrosion. Also,<br />

flaking of the nickel can occur as the base<br />

material corrodes.<br />

Table 8-3. Deterioration of Non-Metallic Materials<br />

Material<br />

Type of Attack to Which<br />

Material is Susceptible<br />

Appearance of Deterioration<br />

Acrylic UV light, moisture solvents Discoloration, cracking<br />

Adhesive Dirt, UV light, solvent moisture Cracking, peeling<br />

Ceramic Extreme heat Discoloration, cracking<br />

8-6