TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TO</strong> 1-1-<strong>700</strong><br />

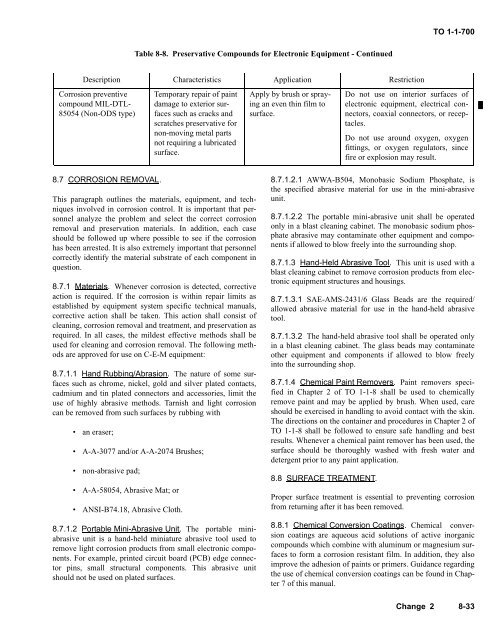

Table 8-8. Preservative Compounds for Electronic Equipment - Continued<br />

Description Characteristics Application Restriction<br />

Corrosion preventive<br />

compound MIL-DTL-<br />

85054 (Non-ODS type)<br />

Temporary repair of paint<br />

damage to exterior surfaces<br />

such as cracks and<br />

scratches preservative for<br />

non-moving metal parts<br />

not requiring a lubricated<br />

surface.<br />

Apply by brush or spraying<br />

an even thin film to<br />

surface.<br />

Do not use on interior surfaces of<br />

electronic equipment, electrical connectors,<br />

coaxial connectors, or receptacles.<br />

Do not use around oxygen, oxygen<br />

fittings, or oxygen regulators, since<br />

fire or explosion may result.<br />

8.7 CORROSION REMOVAL.<br />

This paragraph outlines the materials, equipment, and techniques<br />

involved in corrosion control. It is important that personnel<br />

analyze the problem and select the correct corrosion<br />

removal and preservation materials. In addition, each case<br />

should be followed up where possible to see if the corrosion<br />

has been arrested. It is also extremely important that personnel<br />

correctly identify the material substrate of each component in<br />

question.<br />

8.7.1 Materials. Whenever corrosion is detected, corrective<br />

action is required. If the corrosion is within repair limits as<br />

established by equipment system specific technical manuals,<br />

corrective action shall be taken. This action shall consist of<br />

cleaning, corrosion removal and treatment, and preservation as<br />

required. In all cases, the mildest effective methods shall be<br />

used for cleaning and corrosion removal. The following methods<br />

are approved for use on C-E-M equipment:<br />

8.7.1.1 Hand Rubbing/Abrasion. The nature of some surfaces<br />

such as chrome, nickel, gold and silver plated contacts,<br />

cadmium and tin plated connectors and accessories, limit the<br />

use of highly abrasive methods. Tarnish and light corrosion<br />

can be removed from such surfaces by rubbing with<br />

• an eraser;<br />

• A-A-3077 and/or A-A-2074 Brushes;<br />

• non-abrasive pad;<br />

• A-A-58054, Abrasive Mat; or<br />

• ANSI-B74.18, Abrasive Cloth.<br />

8.7.1.2 Portable Mini-Abrasive Unit. The portable miniabrasive<br />

unit is a hand-held miniature abrasive tool used to<br />

remove light corrosion products from small electronic components.<br />

For example, printed circuit board (PCB) edge connector<br />

pins, small structural components. This abrasive unit<br />

should not be used on plated surfaces.<br />

8.7.1.2.1 AWWA-B504, Monobasic Sodium Phosphate, is<br />

the specified abrasive material for use in the mini-abrasive<br />

unit.<br />

8.7.1.2.2 The portable mini-abrasive unit shall be operated<br />

only in a blast cleaning cabinet. The monobasic sodium phosphate<br />

abrasive may contaminate other equipment and components<br />

if allowed to blow freely into the surrounding shop.<br />

8.7.1.3 Hand-Held Abrasive Tool. This unit is used with a<br />

blast cleaning cabinet to remove corrosion products from electronic<br />

equipment structures and housings.<br />

8.7.1.3.1 SAE-AMS-2431/6 Glass Beads are the required/<br />

allowed abrasive material for use in the hand-held abrasive<br />

tool.<br />

8.7.1.3.2 The hand-held abrasive tool shall be operated only<br />

in a blast cleaning cabinet. The glass beads may contaminate<br />

other equipment and components if allowed to blow freely<br />

into the surrounding shop.<br />

8.7.1.4 Chemical Paint Removers. Paint removers specified<br />

in Chapter 2 of <strong>TO</strong> 1-1-8 shall be used to chemically<br />

remove paint and may be applied by brush. When used, care<br />

should be exercised in handling to avoid contact with the skin.<br />

The directions on the container and procedures in Chapter 2 of<br />

<strong>TO</strong> 1-1-8 shall be followed to ensure safe handling and best<br />

results. Whenever a chemical paint remover has been used, the<br />

surface should be thoroughly washed with fresh water and<br />

detergent prior to any paint application.<br />

8.8 SURFACE TREATMENT.<br />

Proper surface treatment is essential to preventing corrosion<br />

from returning after it has been removed.<br />

8.8.1 Chemical Conversion Coatings. Chemical conversion<br />

coatings are aqueous acid solutions of active inorganic<br />

compounds which combine with aluminum or magnesium surfaces<br />

to form a corrosion resistant film. In addition, they also<br />

improve the adhesion of paints or primers. Guidance regarding<br />

the use of chemical conversion coatings can be found in Chapter<br />

7 of this manual.<br />

Change 2 8-33