TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TO</strong> 1-1-<strong>700</strong><br />

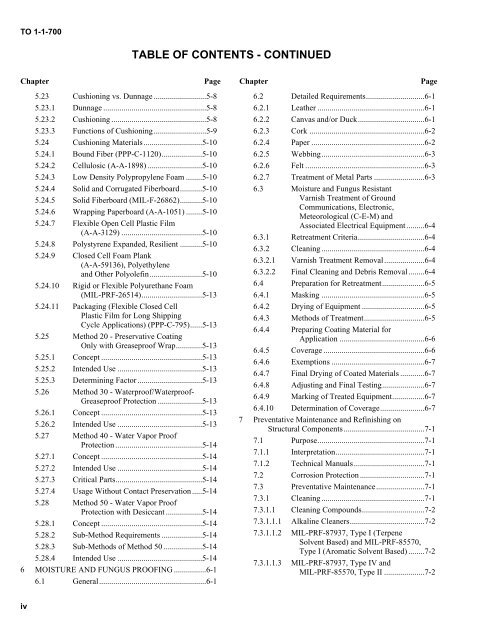

TABLE OF CONTENTS - CONTINUED<br />

Chapter Page Chapter Page<br />

5.23 Cushioning vs. Dunnage ..........................5-8<br />

5.23.1 Dunnage ...................................................5-8<br />

5.23.2 Cushioning ...............................................5-8<br />

5.23.3 Functions of Cushioning..........................5-9<br />

5.24 Cushioning Materials.............................5-10<br />

5.24.1 Bound Fiber (PPP-C-1120)....................5-10<br />

5.24.2 Cellulosic (A-A-1898) ...........................5-10<br />

5.24.3 Low Density Polypropylene Foam ........5-10<br />

5.24.4 Solid and Corrugated Fiberboard...........5-10<br />

5.24.5 Solid Fiberboard (MIL-F-26862)...........5-10<br />

5.24.6 Wrapping Paperboard (A-A-1051) ........5-10<br />

5.24.7 Flexible Open Cell Plastic Film<br />

(A-A-3129) ........................................5-10<br />

5.24.8 Polystyrene Expanded, Resilient ...........5-10<br />

5.24.9 Closed Cell Foam Plank<br />

(A-A-59136), Polyethylene<br />

and Other Polyolefin..........................5-10<br />

5.24.10 Rigid or Flexible Polyurethane Foam<br />

(MIL-PRF-26514)..............................5-13<br />

5.24.11 Packaging (Flexible Closed Cell<br />

Plastic Film for Long Shipping<br />

Cycle Applications) (PPP-C-795)......5-13<br />

5.25 Method 20 - Preservative Coating<br />

Only with Greaseproof Wrap.............5-13<br />

5.25.1 Concept ..................................................5-13<br />

5.25.2 Intended Use ..........................................5-13<br />

5.25.3 Determining Factor ................................5-13<br />

5.26 Method 30 - Waterproof/Waterproof-<br />

Greaseproof Protection ......................5-13<br />

5.26.1 Concept ..................................................5-13<br />

5.26.2 Intended Use ..........................................5-13<br />

5.27 Method 40 - Water Vapor Proof<br />

Protection ...........................................5-14<br />

5.27.1 Concept ..................................................5-14<br />

5.27.2 Intended Use ..........................................5-14<br />

5.27.3 Critical Parts...........................................5-14<br />

5.27.4 Usage Without Contact Preservation.....5-14<br />

5.28 Method 50 - Water Vapor Proof<br />

Protection with Desiccant ..................5-14<br />

5.28.1 Concept ..................................................5-14<br />

5.28.2 Sub-Method Requirements ....................5-14<br />

5.28.3 Sub-Methods of Method 50 ...................5-14<br />

5.28.4 Intended Use ..........................................5-14<br />

6 MOISTURE AND FUNGUS PROOFING ................6-1<br />

6.1 General.....................................................6-1<br />

6.2 Detailed Requirements.............................6-1<br />

6.2.1 Leather .....................................................6-1<br />

6.2.2 Canvas and/or Duck.................................6-1<br />

6.2.3 Cork .........................................................6-2<br />

6.2.4 Paper ........................................................6-2<br />

6.2.5 Webbing...................................................6-3<br />

6.2.6 Felt ...........................................................6-3<br />

6.2.7 Treatment of Metal Parts .........................6-3<br />

6.3 Moisture and Fungus Resistant<br />

Varnish Treatment of Ground<br />

Communications, Electronic,<br />

Meteorological (C-E-M) and<br />

Associated Electrical Equipment.........6-4<br />

6.3.1 Retreatment Criteria.................................6-4<br />

6.3.2 Cleaning ...................................................6-4<br />

6.3.2.1 Varnish Treatment Removal....................6-4<br />

6.3.2.2 Final Cleaning and Debris Removal........6-4<br />

6.4 Preparation for Retreatment.....................6-5<br />

6.4.1 Masking ...................................................6-5<br />

6.4.2 Drying of Equipment ...............................6-5<br />

6.4.3 Methods of Treatment..............................6-5<br />

6.4.4 Preparing Coating Material for<br />

Application ..........................................6-6<br />

6.4.5 Coverage ..................................................6-6<br />

6.4.6 Exemptions ..............................................6-7<br />

6.4.7 Final Drying of Coated Materials ............6-7<br />

6.4.8 Adjusting and Final Testing.....................6-7<br />

6.4.9 Marking of Treated Equipment................6-7<br />

6.4.10 Determination of Coverage......................6-7<br />

7 Preventative Maintenance and Refinishing on<br />

Structural Components........................................7-1<br />

7.1 Purpose.....................................................7-1<br />

7.1.1 Interpretation............................................7-1<br />

7.1.2 Technical Manuals...................................7-1<br />

7.2 Corrosion Protection ................................7-1<br />

7.3 Preventative Maintenance........................7-1<br />

7.3.1 Cleaning ...................................................7-1<br />

7.3.1.1 Cleaning Compounds...............................7-2<br />

7.3.1.1.1 Alkaline Cleaners.....................................7-2<br />

7.3.1.1.2 MIL-PRF-87937, Type I (Terpene<br />

Solvent <strong>Base</strong>d) and MIL-PRF-85570,<br />

Type I (Aromatic Solvent <strong>Base</strong>d) ........7-2<br />

7.3.1.1.3 MIL-PRF-87937, Type IV and<br />

MIL-PRF-85570, Type II ....................7-2<br />

iv