TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

TO 1-1-700 - Robins Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TO</strong> 1-1-<strong>700</strong><br />

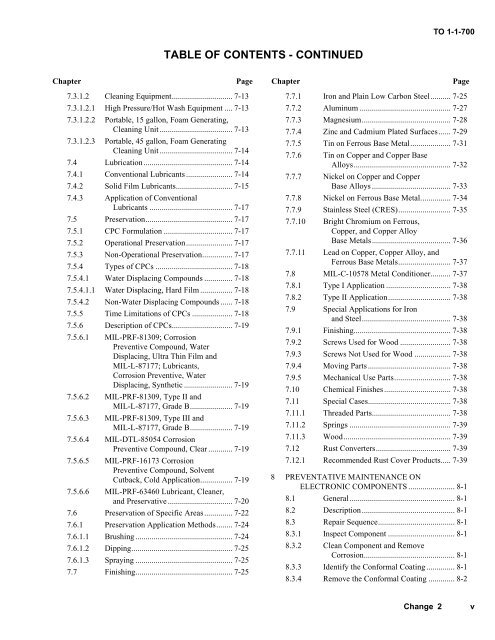

TABLE OF CONTENTS - CONTINUED<br />

Chapter Page Chapter Page<br />

7.3.1.2 Cleaning Equipment.............................. 7-13<br />

7.3.1.2.1 High Pressure/Hot Wash Equipment .... 7-13<br />

7.3.1.2.2 Portable, 15 gallon, Foam Generating,<br />

Cleaning Unit .................................... 7-13<br />

7.3.1.2.3 Portable, 45 gallon, Foam Generating<br />

Cleaning Unit .................................... 7-14<br />

7.4 Lubrication............................................ 7-14<br />

7.4.1 Conventional Lubricants ....................... 7-14<br />

7.4.2 Solid Film Lubricants............................ 7-15<br />

7.4.3 Application of Conventional<br />

Lubricants ......................................... 7-17<br />

7.5 Preservation........................................... 7-17<br />

7.5.1 CPC Formulation .................................. 7-17<br />

7.5.2 Operational Preservation....................... 7-17<br />

7.5.3 Non-Operational Preservation............... 7-17<br />

7.5.4 Types of CPCs ...................................... 7-18<br />

7.5.4.1 Water Displacing Compounds .............. 7-18<br />

7.5.4.1.1 Water Displacing, Hard Film ................ 7-18<br />

7.5.4.2 Non-Water Displacing Compounds ...... 7-18<br />

7.5.5 Time Limitations of CPCs .................... 7-18<br />

7.5.6 Description of CPCs.............................. 7-19<br />

7.5.6.1 MIL-PRF-81309; Corrosion<br />

Preventive Compound, Water<br />

Displacing, Ultra Thin Film and<br />

MIL-L-87177; Lubricants,<br />

Corrosion Preventive, Water<br />

Displacing, Synthetic ........................ 7-19<br />

7.5.6.2 MIL-PRF-81309, Type II and<br />

MIL-L-87177, Grade B..................... 7-19<br />

7.5.6.3 MIL-PRF-81309, Type III and<br />

MIL-L-87177, Grade B..................... 7-19<br />

7.5.6.4 MIL-DTL-85054 Corrosion<br />

Preventive Compound, Clear ............ 7-19<br />

7.5.6.5 MIL-PRF-16173 Corrosion<br />

Preventive Compound, Solvent<br />

Cutback, Cold Application................ 7-19<br />

7.5.6.6 MIL-PRF-63460 Lubricant, Cleaner,<br />

and Preservative ................................ 7-20<br />

7.6 Preservation of Specific Areas.............. 7-22<br />

7.6.1 Preservation Application Methods........ 7-24<br />

7.6.1.1 Brushing ................................................ 7-24<br />

7.6.1.2 Dipping.................................................. 7-25<br />

7.6.1.3 Spraying ................................................ 7-25<br />

7.7 Finishing................................................ 7-25<br />

7.7.1 Iron and Plain Low Carbon Steel.......... 7-25<br />

7.7.2 Aluminum ............................................. 7-27<br />

7.7.3 Magnesium............................................ 7-28<br />

7.7.4 Zinc and Cadmium Plated Surfaces...... 7-29<br />

7.7.5 Tin on Ferrous <strong>Base</strong> Metal.................... 7-31<br />

7.7.6 Tin on Copper and Copper <strong>Base</strong><br />

Alloys................................................ 7-32<br />

7.7.7 Nickel on Copper and Copper<br />

<strong>Base</strong> Alloys ....................................... 7-33<br />

7.7.8 Nickel on Ferrous <strong>Base</strong> Metal............... 7-34<br />

7.7.9 Stainless Steel (CRES).......................... 7-35<br />

7.7.10 Bright Chromium on Ferrous,<br />

Copper, and Copper Alloy<br />

<strong>Base</strong> Metals....................................... 7-36<br />

7.7.11 Lead on Copper, Copper Alloy, and<br />

Ferrous <strong>Base</strong> Metals.......................... 7-37<br />

7.8 MIL-C-10578 Metal Conditioner.......... 7-37<br />

7.8.1 Type I Application ................................ 7-38<br />

7.8.2 Type II Application............................... 7-38<br />

7.9 Special Applications for Iron<br />

and Steel............................................ 7-38<br />

7.9.1 Finishing................................................ 7-38<br />

7.9.2 Screws Used for Wood ......................... 7-38<br />

7.9.3 Screws Not Used for Wood .................. 7-38<br />

7.9.4 Moving Parts ......................................... 7-38<br />

7.9.5 Mechanical Use Parts............................ 7-38<br />

7.10 Chemical Finishes................................. 7-38<br />

7.11 Special Cases......................................... 7-38<br />

7.11.1 Threaded Parts....................................... 7-38<br />

7.11.2 Springs .................................................. 7-39<br />

7.11.3 Wood..................................................... 7-39<br />

7.12 Rust Converters..................................... 7-39<br />

7.12.1 Recommended Rust Cover Products..... 7-39<br />

8 PREVENTATIVE MAINTENANCE ON<br />

ELECTRONIC COMPONENTS ....................... 8-1<br />

8.1 General.................................................... 8-1<br />

8.2 Description.............................................. 8-1<br />

8.3 Repair Sequence...................................... 8-1<br />

8.3.1 Inspect Component ................................. 8-1<br />

8.3.2 Clean Component and Remove<br />

Corrosion............................................. 8-1<br />

8.3.3 Identify the Conformal Coating .............. 8-1<br />

8.3.4 Remove the Conformal Coating ............. 8-2<br />

Change 2<br />

v