- Page 1 and 2:

Con v e r t i n g Wa s t e Agr i c

- Page 3 and 4:

Converting Waste Agricultural Bioma

- Page 5 and 6:

setting and identification of stake

- Page 7 and 8:

ACRONYMS CO2 CV DAP DTIE ESTs E-Was

- Page 9 and 10:

2. Rationale One of the critical ac

- Page 11 and 12:

3. Scope and Limitations In compili

- Page 13 and 14:

4. The Compendium The Project Websi

- Page 15 and 16:

• Basic technology information 9

- Page 17 and 18: Table 1: Cellulosic Waste Biomass C

- Page 19 and 20: Molding Oil Palm fruit residues Sug

- Page 21 and 22: 6. Recommendations The specific rec

- Page 23 and 24: 2-Drum Top Supported Boiler 12 USA,

- Page 25 and 26: HYBRID PF 14 USA, Commercial Crop R

- Page 27 and 28: operation of each to match the stea

- Page 29 and 30: HYBRID RG 15 USA, Commercial Crop R

- Page 31 and 32: All above work in concert to reduce

- Page 33 and 34: HYBRID UF 16 USA, Commercial Crop R

- Page 35 and 36: operation of each to match the stea

- Page 37 and 38: TRI 17 USA, Commercial Crop Residue

- Page 39 and 40: 2-Drum Bottom Supported Boiler 18 U

- Page 41 and 42: power boilers. Examples of Real Lif

- Page 43 and 44: A fully automated continuous system

- Page 45 and 46: Detailed Process Description A. Met

- Page 47 and 48: Examples of Real Life Applications

- Page 49 and 50: Detailed Process Description A. Met

- Page 51 and 52: Examples of Real Life Applications

- Page 53 and 54: 1. The Fibrowatt operation starts o

- Page 55 and 56: HYBRID CG 21 USA, Commercial Crop R

- Page 57 and 58: utilizing the most reliable system

- Page 59 and 60: BTG Flash Pyrolysis Netherlands, Co

- Page 61 and 62: Before processing organic materials

- Page 63 and 64: a. Reactor : This was a downdraft,

- Page 66 and 67: Examples of Real Life Applications

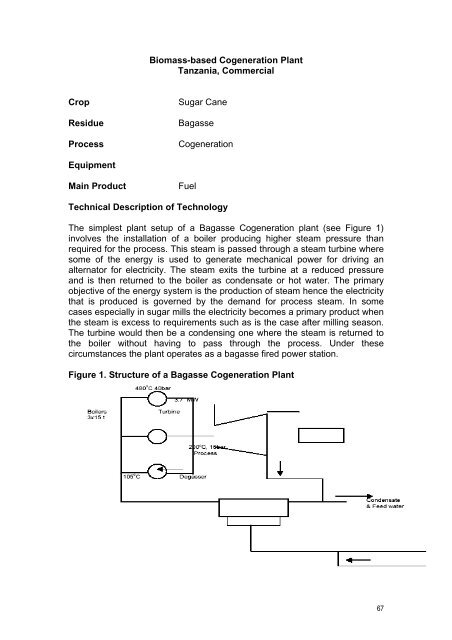

- Page 70 and 71: Main Products: The plant provides i

- Page 72 and 73: Disadvantages to Developing Countri

- Page 74 and 75: Detailed Process Description Kakira

- Page 76 and 77: Example of Real Life Applications C

- Page 78 and 79: Aqueous Phase Reforming (APR) 27 US

- Page 80 and 81: Shelled Corn as Fuel 29 USA, Commer

- Page 82 and 83: Amaizablaze/Nesco, Inc. P. O. Box 3

- Page 84 and 85: HS-Tarm 5 Main Street, P.O. Box 285

- Page 86 and 87: Lock Haven, PA 17745 800-582-4317 h

- Page 88 and 89: P.O. Box 2075, Mankato, MN 56002 80

- Page 90 and 91: The result is wood (biomass) can be

- Page 92 and 93: Biomass Heating System 35 UK, Comme

- Page 94 and 95: Supplier R.D. Associates, Ltd. Fuel

- Page 96 and 97: Figure 5: KSM Drop Cell Unit Some o

- Page 98 and 99: There is a tendency for fly ash to

- Page 100 and 101: AgriPower 36 USA, Commercial Crop R

- Page 102 and 103: BioMax 25 37 USA, Commercial Crop R

- Page 104 and 105: 102

- Page 106 and 107: Solar-Biomass Hybrid Cabinet Dryer

- Page 108 and 109: Two doors were designed for easy lo

- Page 110 and 111: Asbestos gaskets are used while con

- Page 112 and 113: The ash scraper slides through a cy

- Page 114 and 115: flange attached at its bottom; this

- Page 116 and 117: Other fuels such as saw dust brique

- Page 118 and 119:

The completed hybrid solar-biomass

- Page 120 and 121:

Greenfire 41 USA, Commercial Crop R

- Page 122 and 123:

Mayon Turbo Stove and Lo Trau Stove

- Page 124 and 125:

Social Considerations The stove was

- Page 126 and 127:

Commercial Gasifier 49 Philippines,

- Page 128 and 129:

The Modul-Pak ® boiler is a hybrid

- Page 130 and 131:

Suppliers Energy Quest, Inc. 850 So

- Page 132 and 133:

as well as the extraction, recovery

- Page 134 and 135:

oil production period in the mills.

- Page 136 and 137:

weatherproof and sound-attenuating

- Page 138 and 139:

Primenergy R-18 Gasifier producing

- Page 140 and 141:

Low-cost 500 kW thermal rice hull c

- Page 142 and 143:

Kansai Carbonized Rice Husk Gasifie

- Page 144 and 145:

Colusa Rice Straw / Hulls Technolog

- Page 146 and 147:

The customized harvester collects t

- Page 148 and 149:

Rice Husk Gasifier Philippines, Com

- Page 150 and 151:

2.5 MW Cogeneration Plant 65 Thaila

- Page 152 and 153:

San San Rice Husk Stove Myanmar, Co

- Page 154 and 155:

The technology of rice husk gasifie

- Page 156 and 157:

of trees can be controlled. This wo

- Page 158 and 159:

includes an automatic feeder, which

- Page 160 and 161:

Maligaya Rice Hull Stove 74 Philipp

- Page 162 and 163:

Parameters for Procurement Specific

- Page 164 and 165:

162

- Page 166 and 167:

a 100KW capacity Rice-Husk based Ga

- Page 168 and 169:

Rice husk briquette fuel 84 Banglad

- Page 170 and 171:

aised to US$ 6.84 million from the

- Page 172 and 173:

ease of removal of the char, a grat

- Page 174 and 175:

The rice husk gas burner for bakery

- Page 176 and 177:

Engineering and Environmental Manag

- Page 178 and 179:

Depending on the type of fuel it ha

- Page 180 and 181:

mode, all of the steam directed to

- Page 182 and 183:

pyrolysis) with air or oxygen at te

- Page 184 and 185:

R S for in-kind repair of boilers a

- Page 186 and 187:

Wood Biomass Electricity Generator

- Page 188 and 189:

Advantages to Developing Countries

- Page 190 and 191:

Celunol's "wet" biomass conversion

- Page 192 and 193:

up to 1.3 million liters of cellulo

- Page 194 and 195:

This process is done in shredder ma

- Page 196 and 197:

The minimal price established is $C

- Page 198 and 199:

196

- Page 200 and 201:

Telephone (303) 933-3135 FAX (303)

- Page 202 and 203:

Solar-Biomass Hybrid Cabinet Dryer

- Page 204 and 205:

The stove uses cylindrical honeycom

- Page 206 and 207:

Research Centre for Applied Science

- Page 208 and 209:

air. Woody biomass available in ple

- Page 210 and 211:

Dry Grind Ethanol 99 USA, Under Con

- Page 212 and 213:

Price Ethanol sells as a commodity

- Page 214 and 215:

1 Figure 1. Design of the dryer Det

- Page 216 and 217:

footings made of brick and mortar.

- Page 218 and 219:

placed inside mild steel shell of l

- Page 220 and 221:

Biological Hydrogen Production from

- Page 222 and 223:

ioprocess for hydrogen production f

- Page 224 and 225:

a. Reactor: This was a downdraft, t

- Page 226 and 227:

Transpired Collector Solar-Biomass

- Page 228 and 229:

Drying chamber The drying chamber c

- Page 230 and 231:

Annexure 3 EST for Energy Conversio

- Page 232 and 233:

Detailed Process Description Figure

- Page 234 and 235:

Forest Products Research and Develo

- Page 236 and 237:

Advanced Gasification-Combustion (A

- Page 238 and 239:

Wood wool cement board (WWCB) Cemen

- Page 240 and 241:

Furnace-Type Lumber Dryer 105 Phili

- Page 242 and 243:

(i) Charring Drum. The charring dru

- Page 244 and 245:

The mould set is filled with the mi

- Page 246 and 247:

Solar Collector The solar collector

- Page 248 and 249:

Fluidized Bed Combustor for Steam G

- Page 250 and 251:

Small-Scale Biomass Pyrolyzer for F

- Page 252 and 253:

chips) aside from palay and allows

- Page 254 and 255:

Detailed Process Description There

- Page 256 and 257:

The IRRI DR-1 Batch Dryer 117 Phili

- Page 258 and 259:

Rice Hull Furnace attached to a blo

- Page 260 and 261:

was not continuously discharged fro

- Page 262 and 263:

Detailed Process Description Drying

- Page 264 and 265:

Rice Hull Ash Cement (RHAC) Hollow

- Page 266 and 267:

Annexure 4 EST for Material Convers

- Page 268 and 269:

Through a joint venture component m

- Page 270 and 271:

Abaca Mechanical Tuxer 129 Philippi

- Page 272 and 273:

Economic instruments for overcoming

- Page 274 and 275:

Figure 2. Fiber Twisting Machine

- Page 276 and 277:

Example of Real Life Applications C

- Page 278 and 279:

Main Products: Cellulosic Ethanol O

- Page 280 and 281:

converted to a high-carbon char mat

- Page 282 and 283:

NovaGreen Biomass Ethanol Separatio

- Page 284 and 285:

Advantages to Developing Countries

- Page 286 and 287:

Detailed Process Description 133 On

- Page 288 and 289:

286

- Page 290 and 291:

agricultural waste could theoretica

- Page 292 and 293:

downstream value-added products whe

- Page 294 and 295:

Bio-Enriched Method (Trichoderma an

- Page 296 and 297:

Increases yield. Improves water-hol

- Page 298 and 299:

Environmental Considerations 141 Co

- Page 300 and 301:

298

- Page 302 and 303:

150 150 http://www.kinseiseishi.co.

- Page 304 and 305:

152 Type of non-woven materials Che

- Page 306 and 307:

Bale as feedstock USA, Commercial C

- Page 308 and 309:

Price of Machine : refer to the tab

- Page 310 and 311:

2. Cooking the Fiber: A rope is lai

- Page 312 and 313:

9. Weaving: Water is sprayed on the

- Page 314 and 315:

Decorticating Machine and Motorised

- Page 316 and 317:

usually contains two spindles set i

- Page 318 and 319:

tradition and, moreover, the range

- Page 320 and 321:

318

- Page 322 and 323:

Over 3.5 million coconut farmers ar

- Page 324 and 325:

The blades also propel coir fibre t

- Page 326 and 327:

Economic instruments for overcoming

- Page 328 and 329:

first using the drum method or the

- Page 330 and 331:

Job Potential: Farmers' cooperative

- Page 332 and 333:

Soundproofing and Insulating Materi

- Page 334 and 335:

The environmental impact is signifi

- Page 336 and 337:

. Suppliers K.E.F.I. - Kenaf Eco Fi

- Page 338 and 339:

Detailed Process Descriptions: 1. H

- Page 340 and 341:

Examples of Real Life Applications

- Page 342 and 343:

In a two-stage setup, the target wi

- Page 344 and 345:

companies with expertise in this we

- Page 346 and 347:

Mezcal Production from Maguey Phili

- Page 348 and 349:

5. Crushing the agave. The roasted

- Page 350 and 351:

Method of Propagation Applying fert

- Page 352 and 353:

Main Products 198 Abaca fiber comes

- Page 354 and 355:

Being a high-priced fabric has prac

- Page 356 and 357:

Detailed Process Description 202 Me

- Page 358 and 359:

Rice Husk basket Burner India, Comm

- Page 360 and 361:

The ash should be white or grey wit

- Page 362 and 363:

Paper from Rice Straw Cyprus, Comme

- Page 364 and 365:

1. Vatting - Fill your vat halfway

- Page 366 and 367:

Ethanol Production by Acid Hydrolys

- Page 368 and 369:

improvements would provide cost sav

- Page 370 and 371:

Detailed Process Description 7. Ric

- Page 372 and 373:

Plywood from Sorghum China, Commerc

- Page 374 and 375:

Example of Real Life Applications L

- Page 376 and 377:

Figure 1. Schematic of gasifier-pow

- Page 378 and 379:

hull is a processing by-product of

- Page 380 and 381:

The size of the mill or number of m

- Page 382 and 383:

Figure 3. A 12-ft continuous evapor

- Page 384 and 385:

The finished syrup is thoroughly st

- Page 386 and 387:

Drinking Vinegar from Sweet Sorghum

- Page 388 and 389:

only four months. Ethanol, a cheape

- Page 390 and 391:

Davis & Standard Twin Screw Extrude

- Page 392 and 393:

Environmental and Social Considerat

- Page 394 and 395:

Annexure 5 EST for Material Convers

- Page 396 and 397:

Detailed Process Description Figure

- Page 398 and 399:

operational analysis be carried out

- Page 400 and 401:

Figure 2. Hopper or Feeder The comp

- Page 402 and 403:

Broin Fractionation (BFRAC) 218 USA

- Page 404 and 405:

Collaboration with other companies

- Page 406 and 407:

NET INCOME Before Tax = 237, 600 -

- Page 408 and 409:

Cornstalk Flash Volatilization USA,

- Page 410 and 411:

Decentralized Wastewater Treatment

- Page 412 and 413:

degrades the wastes. The algal pond

- Page 414 and 415:

Job Potential: 231 Preparing the so

- Page 416 and 417:

Annexure 6 EST for Material Convers

- Page 418 and 419:

Operations and Maintenance Requirem

- Page 420 and 421:

Detailed Process Description There

- Page 422 and 423:

Biochar 237 USA, Research Crop Resi

- Page 424 and 425:

422

- Page 426 and 427:

424

- Page 428 and 429:

Detailed Process Description: 241 2

- Page 430 and 431:

In addition to functioning as a thi

- Page 432 and 433:

The underflow from the first stage

- Page 434 and 435:

y essentially dry process technique

- Page 436 and 437:

industrial uses. It consists of mol

- Page 438 and 439:

yeast for high alcohol, and high-te

- Page 440 and 441:

About the UNEP Division of Technolo