TO LORD

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A<br />

Reflector<br />

to ^spefld,<br />

Tufcold<br />

Reflectors<br />

Projection and Sound—<br />

Continued from page 10<br />

less in its medium position, that is to say,<br />

when it swings out toward either side to the<br />

same degree.<br />

Check the loop former while the film<br />

runs. Holding the small knurled part reduces<br />

the loop; holding the big knurled part enlarges<br />

the loop above the Maltese cross intermittent<br />

sprocket.<br />

In order to exchange the plastic guide<br />

rollers, remove the locking discs from the<br />

shafts and take off the rollers. Clean the<br />

rollers which do not run smoothly and put<br />

lubrication on the roller shafts before<br />

a little<br />

replacing them. Keep the rollers free of dust<br />

and dirt.<br />

Takeup Sprocket<br />

The takeup sprocket is mounted onto the<br />

shaft of the takeup bearing together with<br />

loop former. To remove the takeup sprocket<br />

together with loop former, lift the lay-on<br />

roller, turning the knurled screw of the loop<br />

former until the hexagon socket screw becomes<br />

visible behind a hole in the sprocket.<br />

Then remove the screw entirely and take off<br />

the loop former together with the takeup<br />

sprocket. When replacing these parts, watch<br />

that the driving pin of the loop former engages<br />

with the corresponding bore in the<br />

sprocket.<br />

To remove the intermittent sprocket,<br />

turn the inching wheel until the intermittent<br />

sprocket comes to a standstill and then<br />

loosen the conical screw. Give the inching<br />

wheel another quarter-turn to prevent any<br />

damage to the Maltese cross. This should be<br />

done even after the intermittent sprocket<br />

has come to a standstill. As an additional<br />

precautionary safety move to prevent damage<br />

to the Maltese cross, hold this sprocket<br />

while loosening the screw. When replacing<br />

the intermittent sprocket, watch that the<br />

fixing pin on the intermittent shaft engages<br />

with the groove in the intermittent sprocket.<br />

Then, push the sprocket inward and up to<br />

the stop,<br />

tightening the retaining screw very<br />

carefully and without too much force.<br />

To adjust the upper roller holder on the<br />

projector head, loosen the clamping screw<br />

of the roller shaft to a point where it<br />

cannot be moved any more. Then, turn the<br />

shaft laterally so that the film does not<br />

buckle on either side of the roller holder.<br />

To exchange the plastic or velvet bands<br />

on the aperture holder, first open the film<br />

gate, loosen the socket screw and remove<br />

the aperture holder. Release the tension on<br />

the band by loosening the knurled screw.<br />

Loosen the hexagon socket screw of the<br />

clamping plate at the bottom of the aperture<br />

holder. Then, remove the bottom end of<br />

the bands and then the top ends.<br />

When installing new bands, first fit them<br />

into the top clamping lever. Clamp them<br />

tightly by means of the clamping plate after<br />

applying some pre-tension by hand. After<br />

installing the new bands, make sure that the<br />

respective tensioning springs fit into the<br />

respective grooves in the clamping bolt<br />

Then watch that the clamping bolt is prop<br />

erly seated in the clamping levers.<br />

When the film runs, tighten the bands to<br />

a point where perfect picture steadiness with<br />

a minimum of film running noise is guaran<br />

teed. If, during projection, it should become<br />

obvious that the tensioning bands cannot be<br />

sufficiently tightened, exchange the tensioning<br />

spring in the aperture holder. Excess<br />

tension may damage the perforations oi<br />

1<br />

even cause a film break. On the other hand<br />

insufficient tension will cause unsatisfactory<br />

picture steadiness. It is important, therefore<br />

to make adjustments as instructed. Then<br />

should be just enough tension to hold thi<br />

picture steady on the screen.<br />

Removing the aperture holder is accomp<br />

lished by first removing the film gate an<<br />

then loosening the hexagon socket screv<br />

dler<br />

Continued on page U<br />

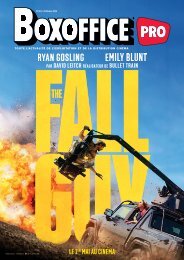

Aperture and lens heat reduced. First<br />

surface Dichroic Reflectors with two<br />

year coating guarantee, project more<br />

light because it is reflected from the<br />

front surface, without passing through<br />

the glass.<br />

Strong also produces silvered reflectors<br />

for all makes of lamps and is<br />

able to supply reflectors for many<br />

discontinued lamp models.<br />

•<br />

STRONG ELECTRIC<br />

Phone (419) 248-3741<br />

11 City Park Avenue • Toledo, Ohio 43697<br />

A SUBSIDIARY OF CANRAD-HAHOVIA<br />

SNAP-LOK & SLOTTED LETTERS<br />

SIZES FROM 4" <strong>TO</strong> 31"<br />

a^<br />

FLAT LETTERS (PRON<strong>TO</strong>)<br />

SOLID STROKE<br />

OR 3 DIMENSIONAL<br />

SIZES FROM 3" <strong>TO</strong> 24"<br />

in California call collect (213) 321-5641<br />

14824 S. Main St., Gardena, Co 90248<br />

(write for our free catalog today)<br />

the:<br />

SMHMU MINI<br />

14<br />

The MODERN THEATRE SECTIC<br />

I