Art and Design A comprehensive guide for creative artists - Aaltodoc

Art and Design A comprehensive guide for creative artists - Aaltodoc

Art and Design A comprehensive guide for creative artists - Aaltodoc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Rich(1998, 250) offers a reasonable explanation: “A study of<br />

Michelangelo's nearly finished stone carvings show that<br />

he worked in a manner similar to Greeks <strong>and</strong> did not make<br />

much use of the flat chisel, proceeding from the use of<br />

the claw chisel to finishing stone abrasives.” Here we see<br />

that stone especially Marble was a common material <strong>for</strong><br />

sculptors like Michelangelo, which was very hard <strong>for</strong> them<br />

to finish it.<br />

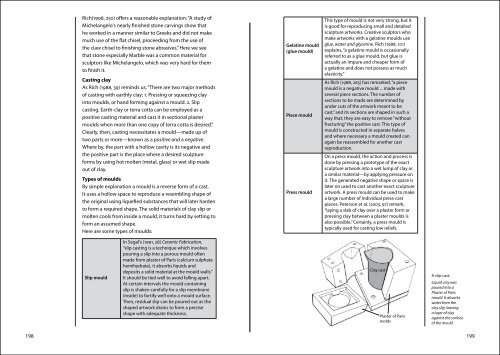

Casting clay<br />

As Rich (1988, 39) reminds us, “There are two major methods<br />

of casting with earthly clay; 1. Pressing or squeezing clay<br />

into moulds, or h<strong>and</strong> <strong>for</strong>ming against a mould. 2. Slip<br />

casting. Earth-clay or terra cotta can be employed as a<br />

positive casting material <strong>and</strong> cast it in sectional plaster<br />

moulds when more than one copy of terra cotta is desired.”<br />

Clearly, then, casting necessitates a mould—made up of<br />

two parts or more—known as a positive <strong>and</strong> a negative.<br />

Where by, the part with a hollow cavity is its negative <strong>and</strong><br />

the positive part is the place where a desired sculpture<br />

<strong>for</strong>ms by using hot molten (metal, glass) or wet slip made<br />

out of clay.<br />

Types of moulds<br />

By simple explanation a mould is a reverse <strong>for</strong>m of a cast.<br />

It uses a hollow space to reproduce a resembling shape of<br />

the original using liquefied substances that will later harden<br />

to <strong>for</strong>m a required shape. The solid materials of clay slip or<br />

molten cools from inside a mould, it turns hard by setting to<br />

<strong>for</strong>m an assumed shape.<br />

Here are some types of moulds:<br />

Slip mould<br />

In Segal's (1991, 28) Ceramic Fabrication,<br />

“slip casting is a technique which involves<br />

pouring a slip into a porous mould often<br />

made from plaster of Paris (calcium sulphate<br />

hemihydrate), it absorbs liquids <strong>and</strong><br />

deposits a solid material at the mould walls.”<br />

It should be tied well to avoid falling apart.<br />

At certain intervals the mould containing<br />

slip is shaken carefully <strong>for</strong> a slip membrane<br />

(inside) to <strong>for</strong>tify well onto a mould surface.<br />

Then, residual slip can be poured out as the<br />

shaped artwork drains to <strong>for</strong>m a precise<br />

shape with adequate thickness.<br />

Gelatine mould<br />

(glue mould)<br />

Piece mould<br />

Press mould<br />

This type of mould is not very strong, but it<br />

is good <strong>for</strong> reproducing small <strong>and</strong> detailed<br />

sculpture artworks. Creative sculptors who<br />

make artworks with a gelatine moulds use<br />

glue, water <strong>and</strong> glycerine. Rich (1988, 101)<br />

explains, “a gelatine mould is occasionally<br />

referred to as a glue mould, but glue is<br />

actually an impure <strong>and</strong> cheaper <strong>for</strong>m of<br />

a gelatine <strong>and</strong> does not possess as much<br />

elasticity.”<br />

As Rich (1988, 265) has remarked, “a piece<br />

mould is a negative mould ... made with<br />

several piece sections. The number of<br />

sections to be made are determined by<br />

under cuts of the artwork meant to be<br />

cast,” <strong>and</strong> its sections are shaped in such a<br />

way that; they are easy to remove “without<br />

fracturing” the positive cast. This type of<br />

mould is constructed in separate halves<br />

<strong>and</strong> where necessary a mould created can<br />

again be reassembled <strong>for</strong> another cast<br />

reproduction.<br />

On a press mould, the action <strong>and</strong> process is<br />

done by pressing a prototype of the exact<br />

sculpture artwork into a wet lump of clay or<br />

a similar material—by applying pressure on<br />

it. The generated negative shape or space is<br />

later on used to cast another exact sculpture<br />

artwork. A press mould can be used to make<br />

a large number of individual press-cast<br />

pieces. Peterson et al. (2003, 97) remark,<br />

“laying a slab of clay over a plaster <strong>for</strong>m or<br />

pressing clay between a plaster moulds is<br />

also possible.” Certainly, a press mould is<br />

typically used <strong>for</strong> casting low reliefs.<br />

A slip-cast.<br />

Liquid clay was<br />

poured into a<br />

Plaster of Paris<br />

mould. It absorbs<br />

water from the<br />

clay slip, leaving<br />

a layer of clay<br />

against the surface<br />

of the mould.<br />

198 199<br />

Clay cast<br />

Plaster of Paris<br />

molds