Art and Design A comprehensive guide for creative artists - Aaltodoc

Art and Design A comprehensive guide for creative artists - Aaltodoc

Art and Design A comprehensive guide for creative artists - Aaltodoc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

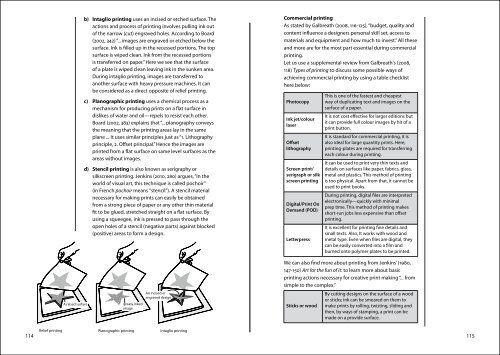

A raised surface<br />

b) Intaglio printing uses an incised or etched surface. The<br />

actions <strong>and</strong> process of printing involves pulling ink out<br />

of the narrow (cut) engraved holes. According to Board<br />

(2002, 342) “... images are engraved or etched below the<br />

surface. Ink is filled up in the recessed portions. The top<br />

surface is wiped clean. Ink from the recessed portions<br />

is transferred on paper.” Here we see that the surface<br />

of a plate is wiped clean leaving ink in the sunken area.<br />

During intaglio printing, images are transferred to<br />

another surface with heavy pressure machines. It can<br />

be considered as a direct opposite of relief printing.<br />

c) Planographic printing uses a chemical process as a<br />

mechanism <strong>for</strong> producing prints on a flat surface in<br />

dislikes of water <strong>and</strong> oil—repels to resist each other.<br />

Board (2002, 383) explains that “... planography conveys<br />

the meaning that the printing areas lay in the same<br />

plane ... It uses similar principles just as “1. Lithography<br />

principle, 2. Offset principal.” Hence the images are<br />

printed from a flat surface on same level surfaces as the<br />

areas without images.<br />

d) Stencil printing is also known as serigraphy or<br />

silkscreen printing. Jenkins (2010, 280) argues, “In the<br />

world of visual art, this technique is called pochoir”<br />

(in French pochoir means "stencil”). A stencil material<br />

necessary <strong>for</strong> making prints can easily be obtained<br />

from a strong piece of paper or any other thin material<br />

fit to be glued, stretched straight on a flat surface. By<br />

using a squeegee, ink is pressed to pass through the<br />

open holes of a stencil (negative parts) against blocked<br />

(positive) areas to <strong>for</strong>m a design.<br />

An incised or<br />

engraved design<br />

greasy inked<br />

image<br />

Relief printing Planographic printing Intaglio printing<br />

Commercial printing<br />

As stated by Galbreath (2008, 116-125), “budget, quality <strong>and</strong><br />

content influence a designers personal skill set, access to<br />

materials <strong>and</strong> equipment <strong>and</strong> how much to invest.” All these<br />

<strong>and</strong> more are <strong>for</strong> the most part essential during commercial<br />

printing.<br />

Let us use a supplemental review from Galbreath's (2008,<br />

118) Types of printing to discuss some possible ways of<br />

achieving commercial printing by using a table checklist<br />

here below:<br />

Photocopy<br />

Ink jet/colour<br />

laser<br />

Offset<br />

lithography<br />

Screen print/<br />

serigraph or silk<br />

screen printing<br />

Digital/Print On<br />

Dem<strong>and</strong> (POD)<br />

Letterpress<br />

This is one of the fastest <strong>and</strong> cheapest<br />

way of duplicating text <strong>and</strong> images on the<br />

surface of a paper.<br />

It is not cost effective <strong>for</strong> larger editions but<br />

it can provide full colour images by hit of a<br />

print button.<br />

It is st<strong>and</strong>ard <strong>for</strong> commercial printing, it is<br />

also ideal <strong>for</strong> large quantity prints. Here,<br />

printing-plates are required <strong>for</strong> transferring<br />

each colour during printing.<br />

It can be used to print very thin texts <strong>and</strong><br />

details on surfaces like paper, fabrics, glass,<br />

metal <strong>and</strong> plastics. This method of printing<br />

is too physical. Apart from that, it cannot be<br />

used to print books.<br />

During printing, digital files are interpreted<br />

electronically—quickly with minimal<br />

prep time. This method of printing makes<br />

short-run jobs less expensive than offset<br />

printing.<br />

It is excellent <strong>for</strong> printing fine details <strong>and</strong><br />

small texts. Also, It works with wood <strong>and</strong><br />

metal type. Even when files are digital, they<br />

can be easily converted into a film <strong>and</strong><br />

burned onto polymer plates to be printed.<br />

We can also find more about printing from Jenkins’ (1980,<br />

147-150) <strong>Art</strong> <strong>for</strong> the fun of it: to learn more about basic<br />

printing actions necessary <strong>for</strong> <strong>creative</strong> print making “... from<br />

simple to the complex.”<br />

By cutting designs on the surface of a wood<br />

or sticks; ink can be smeared on them to<br />

Sticks or wood make prints by rolling, twisting, sliding <strong>and</strong><br />

then, by ways of stamping, a print can be<br />

made on a provide surface.<br />

114 115