- Page 2 and 3:

Practical Data Acquisition forInstr

- Page 4 and 5:

Practical Data Acquisition forInstr

- Page 6 and 7:

In less than a decade, the PC has b

- Page 8 and 9:

PrefaceContentsxvii1 Introduction 1

- Page 10 and 11:

Contents vii4.2.1 Hardware interrup

- Page 12 and 13:

Contents ix6.2.3 Functional descrip

- Page 14 and 15:

Contents xi9.1 Ethernet and fieldbu

- Page 16 and 17:

Contents xiii12.5.2 Pin assignments

- Page 18 and 19:

Contents xvType R thermocouple 384T

- Page 20 and 21:

A data acquisition and control syst

- Page 22 and 23:

FilteringIn noisy environments, it

- Page 24 and 25:

are capable of programmed I/O and i

- Page 26 and 27:

Plug-in expansion boards are common

- Page 28 and 29:

50 mRS-232 Communication InterfaceS

- Page 30 and 31:

speeds are of the order of 1 Mbyte/

- Page 32 and 33:

14 Practical Data Acquisition for I

- Page 34 and 35:

16 Practical Data Acquisition for I

- Page 36 and 37:

18 Practical Data Acquisition for I

- Page 38 and 39:

20 Practical Data Acquisition for I

- Page 40 and 41:

22 Practical Data Acquisition for I

- Page 42 and 43:

24 Practical Data Acquisition for I

- Page 44 and 45:

26 Practical Data Acquisition for I

- Page 46 and 47:

28 Practical Data Acquisition for I

- Page 48 and 49:

30 Practical Data Acquisition for I

- Page 50 and 51:

32 Practical Data Acquisition for I

- Page 52 and 53:

34 Practical Data Acquisition for I

- Page 54 and 55:

3PC based data acquisition (DAQ) sy

- Page 56 and 57:

3.2.3 FilteringIsolation performs s

- Page 58 and 59:

The transfer characteristics of a p

- Page 60 and 61:

Figure 3.7Ideal band pass filter tr

- Page 62 and 63:

Figure 3.11Two-stage Butterworth fi

- Page 64 and 65:

As individual signal conditioning m

- Page 66 and 67:

ThermocouplesDigitalTransmitterDigi

- Page 68 and 69:

Examples of floating signal sources

- Page 70 and 71:

espect to the measurement system gr

- Page 72 and 73:

Figure 3.26Opto-coupler isolation o

- Page 74 and 75:

• Using isolation amplifiers to i

- Page 76 and 77:

Figure 3.31Physical representation

- Page 78 and 79:

field or if the field is caused by

- Page 80 and 81:

Where the shield is grounded (i.e.

- Page 82 and 83:

mines the amount of noise in the ci

- Page 84 and 85:

For full-duplex systems using balan

- Page 86 and 87:

4.1.1 DOSusually consist of a small

- Page 88 and 89:

With the advent of Windows as a gra

- Page 90 and 91:

UNIX shellSimilar to the DOS comman

- Page 92 and 93:

available to the expansion bus. A l

- Page 94 and 95:

4.2.7 Interrupt service routinesIt

- Page 96 and 97:

Whichever CPU is being used, it mus

- Page 98 and 99:

• An I/O device requests a DMA tr

- Page 100 and 101:

Normal DMA using on-board FIFOThe D

- Page 102 and 103:

ferring samples until the counter r

- Page 104 and 105:

The read or write command signals (

- Page 106 and 107:

Shortened 3-BCLK 8-bit memory acces

- Page 108 and 109:

Extended 6-BCLK 16-bit memory acces

- Page 110 and 111:

• A cycle which the expansion boa

- Page 112 and 113:

Figure 4.13Timing chart of a shorte

- Page 114 and 115:

Figure 4.15Timing chart of an exten

- Page 116 and 117:

4.7.2 Expanded memory system (EMS)E

- Page 118 and 119:

The IBM PC and early versions of th

- Page 120 and 121:

Figure 4.17ISA signal mnemonics, si

- Page 122 and 123:

data bus. An example of this happen

- Page 124 and 125:

NOWSThe /NOWS (NO wait state) signa

- Page 126 and 127:

interrupt lines (1RQ13, 8, 2, 1 and

- Page 128 and 129:

one application at a time, it is ne

- Page 130 and 131:

The need for PCs to exchange data w

- Page 132 and 133:

Figure 4.198-bit 21-line I/O board4

- Page 134 and 135:

Address decoding on the 24-line pro

- Page 136 and 137:

The write cycle is considered in th

- Page 138 and 139:

data acquisition and control system

- Page 140 and 141:

Adjustable on-board fixed gain ampl

- Page 142 and 143:

level applied at the input. When a

- Page 144 and 145:

Each step effectively divides the r

- Page 146 and 147:

The operation of a dual slope integ

- Page 148 and 149:

Code widthThis is the fundamental q

- Page 150 and 151:

(a) Unipolar offset error(b) Bipola

- Page 152 and 153:

Changes in temperature result in a

- Page 154 and 155:

1 LSB. Therefore, an ideal A/D conv

- Page 156 and 157:

• The source and level of interru

- Page 158 and 159:

5.3.3 Differential inputsTrue diffe

- Page 160 and 161:

A/D board can divide the input rang

- Page 162 and 163:

a) DC alias caused by sampling at h

- Page 164 and 165:

Figure 5.15Frequency spectrum of or

- Page 166 and 167:

ate be a minimum of about five time

- Page 168 and 169:

Figure 5.20Many aliases combined wi

- Page 170 and 171:

initiated. The data is subsequently

- Page 172 and 173:

Figure 5.22Time skew between channe

- Page 174 and 175:

For each burst trigger, the A/D boa

- Page 176 and 177:

Analog output D/A boardsUnlike high

- Page 178 and 179:

Like the weighted-current source ne

- Page 180 and 181:

The generation of high frequency si

- Page 182 and 183:

• The plug-in connector, which pr

- Page 184 and 185:

Latched digital I/OFor applications

- Page 186 and 187:

y increasing the resistance of R x

- Page 188 and 189:

One advantage of this type of relay

- Page 190 and 191:

Figure 5.36Waveforms showing genera

- Page 192 and 193:

When a counter is configured to ena

- Page 194 and 195:

6The standardization of the RS-232

- Page 196 and 197:

A duplex system is designed for sen

- Page 198 and 199:

Some examples of the HEX and BIN va

- Page 200 and 201:

In summary, the optional settings f

- Page 202 and 203:

At the RS-232 receiver the followin

- Page 204 and 205:

110 850300 800600 7001200 5002400 2

- Page 206 and 207:

• Pin 7: Signal ground (common)Th

- Page 208 and 209:

6.2.5 Examples of RS-232 interfaces

- Page 210 and 211:

terminating resistors, approximatel

- Page 212 and 213:

Another commonly used technique, ba

- Page 214 and 215:

• Line controlThis applies to hal

- Page 216 and 217:

The calculation of the block checks

- Page 218 and 219:

The mechanism of operation of the C

- Page 220 and 221:

Figure 6.18, has appropriate intern

- Page 222 and 223:

77.1 IntroductionAs with other form

- Page 224 and 225:

inserted in the device. This is its

- Page 226 and 227:

How frequently logged data is uploa

- Page 228 and 229:

The following hardware components d

- Page 230 and 231:

In a typical stand-alone data acqui

- Page 232 and 233:

The maximum battery life that can b

- Page 234 and 235:

Input termination resistors, typica

- Page 236 and 237:

Figure 7.13 shows the standard conn

- Page 238 and 239:

interface, even at high speed, the

- Page 240 and 241:

• Use different data formats so t

- Page 242 and 243:

Command errors are reported immedia

- Page 244 and 245:

• Channel scalingThis automatical

- Page 246 and 247:

The channel scan for this type of s

- Page 248 and 249:

Data is logged in a fixed non-ASCII

- Page 250 and 251:

7.9 Stand-alone logger/controllers

- Page 252 and 253:

88.1 IntroductionThe communications

- Page 254 and 255: Figure 8.2GPIB connector (IEEE 488)

- Page 256 and 257: • TalkersA talker is a one-way co

- Page 258 and 259: controller in charge (CIC). The IFC

- Page 260 and 261: Each device connected to the GPIB h

- Page 262 and 263: One of the additional features that

- Page 264 and 265: • The controller temporarily conf

- Page 266 and 267: Table 8.4IEEE 488.2 commandsThe SCP

- Page 268 and 269: Figure 8.9SCPI instrument modelThe

- Page 270 and 271: 99.1 Ethernet and fieldbuses for da

- Page 272 and 273: cabling tray etc and the transceive

- Page 274 and 275: transceiver in the MAU and this is

- Page 276 and 277: Advantages of the system include:

- Page 278 and 279: of a cell as well, but these are ig

- Page 280 and 281: Figure 9.8CSMA/CD collisionsAssume

- Page 282 and 283: • PreambleThis field consists of

- Page 284 and 285: of this figure. Some manufacturers

- Page 286 and 287: Grounding has safety and noise conn

- Page 288 and 289: Just as with any technology, each o

- Page 290 and 291: information. The packet is then pla

- Page 292 and 293: There are two types of connectors,

- Page 294 and 295: HOSTClient SoftwareManages Interfac

- Page 296 and 297: Figure 10.6USB connector pinsThere

- Page 298 and 299: The idle states for low- and high-s

- Page 300 and 301: The interrupt transfer type is used

- Page 302 and 303: than in spending a lot of time and

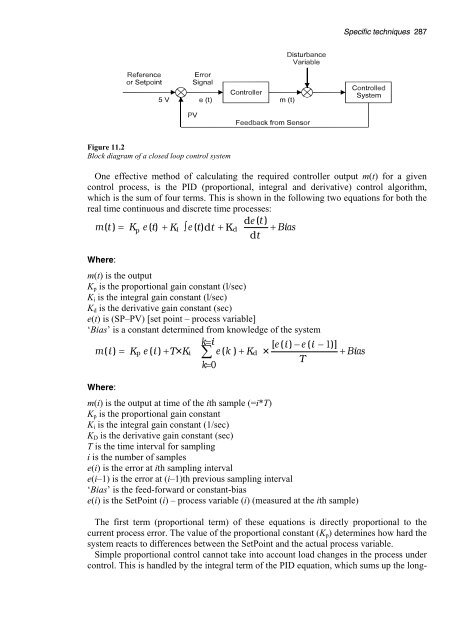

- Page 306 and 307: term error (m) in the system and ad

- Page 308 and 309: 11.2 Capturing high speed transient

- Page 310 and 311: 12IntroductionThe PCMCIA (PCMCIA st

- Page 312 and 313: adapter on a full size computer has

- Page 314 and 315: Pager cards are used in offices and

- Page 316 and 317: Size 85.6 mm × 54.0 mmType I 3.3 m

- Page 318 and 319: The memory only interface is conver

- Page 320 and 321: The AIMS interface supports large d

- Page 322 and 323: 12.8 FutureThe card information str

- Page 324 and 325: A/D conversion timeAddressAddress r

- Page 326 and 327: Back-planeBand pass filterBandwidth

- Page 328 and 329: BufferBusBWCache memoryCCDCCIRCCITT

- Page 330 and 331: pixel is subjected to a mathematica

- Page 332 and 333: data between the computer memory an

- Page 334 and 335: FrameFrame grabberFringingFull dupl

- Page 336 and 337: so that they interlock. The PAL sta

- Page 338 and 339: Lux-secondSI unit of light exposure

- Page 340 and 341: NTSCNull modemNumber of channelsNyq

- Page 342 and 343: PortPPIPre-triggerProgram I/OProgra

- Page 344 and 345: whereby the first gray level of eac

- Page 346 and 347: allowing the user to control basic

- Page 348 and 349: input.TrunkUARTUnipolar inputsUnloa

- Page 350 and 351: Appendix BThe information in this s

- Page 352 and 353: Table B.4Controller 2: 16-bit (AT o

- Page 354 and 355:

B.5 8253/8254 Counter/timer

- Page 356:

Table B.8Memory map for PC/XT/AT

- Page 359 and 360:

Table B.10BIOS data area

- Page 361 and 362:

Table B.15ROMTable B.16AT extended

- Page 363 and 364:

← ↔ ← ← ← ↔

- Page 365 and 366:

Figure B.1Card dimensions for PC/XT

- Page 367 and 368:

Appendix CThis section contains bri

- Page 369 and 370:

the control register of the 8255. T

- Page 371 and 372:

The bits A7 (MSB) down to A0 (LSB)

- Page 373 and 374:

Table C.6Instructions for reading o

- Page 375 and 376:

The program could also enable the I

- Page 377 and 378:

Group AConfiguration Informationto

- Page 379 and 380:

C.11 Single-bit set/resetAny of the

- Page 381 and 382:

Figure C.15Bi-directional bus (mode

- Page 383 and 384:

Figure D.18254 Block diagramFigure

- Page 385 and 386:

Figure D.3TCCTRL registerThe functi

- Page 387 and 388:

This is the data register of the fi

- Page 389 and 390:

• A simple read operation• A co

- Page 391 and 392:

The null count bit indicates if the

- Page 393 and 394:

For even counts: the output is init

- Page 395 and 396:

Appendix EThe IPTS-68 standard defi

- Page 397 and 398:

Number of ranges = 2Range #1 -270 t

- Page 399 and 400:

Number of ranges = 1Range #1 -210 t

- Page 401 and 402:

Range #2 0 to 1372°COrder of polyn

- Page 403 and 404:

Number of Ranges = 4Range #1 -50 to

- Page 405 and 406:

Number of ranges = 2Range #1 -270 t

- Page 407 and 408:

Appendix FF.1 IntroductionAll activ

- Page 409 and 410:

Table F.3 gives the conversion betw

- Page 411 and 412:

The conversion between binary and h

- Page 413 and 414:

F.8 Internal representation of info

- Page 415 and 416:

12 which is equivalent to: 1100-4 S

- Page 417 and 418:

DCDCASDCISDCLDDDIODTDTASDTISENDEOIE

- Page 419 and 420:

STBSTRSSWNST(T)TETACSTADSTAGTCATCST

- Page 421 and 422:

404 IndexDuplex:full duplex 178half

- Page 423 and 424:

406 IndexOpen loop control 285see a

- Page 425:

THIS BOOK WAS DEVELOPED BY IDC TECH