In Fonderia 1 2024

Primo numero del 2024 di In Fonderia

Primo numero del 2024 di In Fonderia

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECNICO<br />

• Portata fino a 700 m³/h<br />

• Velocità del nastro fino a 0,35 m/s<br />

• Larghezze tazze da 500 a 1.600 mm<br />

• Layout customizzabile e design espandibile<br />

• Trasportatore aperto o completamente chiuso<br />

• Nessuna generazione ed emissione di polvere<br />

di silice<br />

• Livello di rumorosità ≤ 75 dB(A)<br />

• Manutenzione ridotta e semplice<br />

• Ridotto consumo energetico.<br />

TRASPORTO TERRA<br />

Il presente lavoro mira a dimostrare l’applicabilità<br />

del trasportatore Superbelt ® B alla movimentazione<br />

della terra di fonderia. I requisiti<br />

dell’applicazione che incidono sul design del<br />

trasportatore sono:<br />

• Elevate capacità di trasporto<br />

• Temperatura della terra anche superiore ai<br />

150÷200°C<br />

• Distribuzione granulometrica della terra<br />

• Emissioni di polvere di silice cristallina respirabile<br />

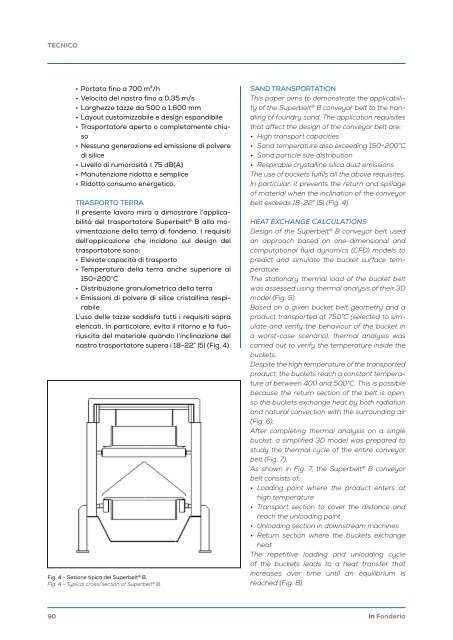

L’uso delle tazze soddisfa tutti i requisiti sopra<br />

elencati. <strong>In</strong> particolare, evita il ritorno e la fuoriuscita<br />

del materiale quando l’inclinazione del<br />

nastro trasportatore supera i 18-22° |5| (Fig. 4).<br />

Fig. 4 - Sezione tipica del Superbelt ® B.<br />

Fig. 4 - Typical cross/section of Superbelt ® B.<br />

SAND TRANSPORTATION<br />

This paper aims to demonstrate the applicability<br />

of the Superbelt ® B conveyor belt to the handling<br />

of foundry sand. The application requisites<br />

that affect the design of the conveyor belt are:<br />

• High transport capacities<br />

• Sand temperature also exceeding 150÷200°C<br />

• Sand particle size distribution<br />

• Respirable crystalline silica dust emissions<br />

The use of buckets fulfils all the above requisites.<br />

<strong>In</strong> particular, it prevents the return and spillage<br />

of material when the inclination of the conveyor<br />

belt exceeds 18-22° |5| (Fig. 4).<br />

HEAT EXCHANGE CALCULATIONS<br />

Design of the Superbelt ® B conveyor belt used<br />

an approach based on one-dimensional and<br />

computational fluid dynamics (CFD) models to<br />

predict and simulate the bucket surface temperature.<br />

The stationary thermal load of the bucket belt<br />

was assessed using thermal analysis of their 3D<br />

model (Fig. 5).<br />

Based on a given bucket belt geometry and a<br />

product transported at 750°C (selected to simulate<br />

and verify the behaviour of the bucket in<br />

a worst-case scenario), thermal analysis was<br />

carried out to verify the temperature inside the<br />

buckets.<br />

Despite the high temperature of the transported<br />

product, the buckets reach a constant temperature<br />

of between 400 and 500°C. This is possible<br />

because the return section of the belt is open,<br />

so the buckets exchange heat by both radiation<br />

and natural convection with the surrounding air<br />

(Fig. 6).<br />

After completing thermal analysis on a single<br />

bucket, a simplified 3D model was prepared to<br />

study the thermal cycle of the entire conveyor<br />

belt (Fig. 7).<br />

As shown in Fig. 7, the Superbelt ® B conveyor<br />

belt consists of:<br />

• Loading point where the product enters at<br />

high temperature<br />

• Transport section to cover the distance and<br />

reach the unloading point<br />

• Unloading section in downstream machines<br />

• Return section where the buckets exchange<br />

heat<br />

The repetitive loading and unloading cycle<br />

of the buckets leads to a heat transfer that<br />

increases over time until an equilibrium is<br />

reached (Fig. 8).<br />

90<br />

<strong>In</strong> <strong>Fonderia</strong>