- Page 1:

PHARMACEUTICAL MANUFACTURING HANDBO

- Page 5 and 6:

PHARMACEUTICAL MANUFACTURING HANDBO

- Page 7 and 8:

CONTRIBUTORS Susanna Abrahms é n -

- Page 9 and 10:

CONTRIBUTORS vii Eddy Castellanos G

- Page 11 and 12:

CONTENTS PREFACE xiii SECTION 1 MAN

- Page 13:

CONTENTS xi 5.11 Transdermal Drug D

- Page 17:

SECTION 1 MANUFACTURING SPECIALTIES

- Page 20 and 21:

4 BIOTECHNOLOGY-DERIVED DRUG PRODUC

- Page 22 and 23:

6 BIOTECHNOLOGY-DERIVED DRUG PRODUC

- Page 24 and 25:

8 BIOTECHNOLOGY-DERIVED DRUG PRODUC

- Page 26 and 27:

10 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 28 and 29:

12 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 30 and 31:

14 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 32 and 33:

16 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 34 and 35:

18 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 36 and 37:

20 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 38 and 39:

22 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 40 and 41:

24 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 42 and 43:

26 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 44 and 45:

28 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 46 and 47:

30 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 48 and 49:

32 BIOTECHNOLOGY-DERIVED DRUG PRODU

- Page 50 and 51:

34 REGULATORY CONSIDERATIONS IN APP

- Page 52 and 53:

36 REGULATORY CONSIDERATIONS IN APP

- Page 54 and 55:

38 REGULATORY CONSIDERATIONS IN APP

- Page 56 and 57:

40 REGULATORY CONSIDERATIONS IN APP

- Page 58 and 59:

42 REGULATORY CONSIDERATIONS IN APP

- Page 60 and 61:

44 REGULATORY CONSIDERATIONS IN APP

- Page 62 and 63:

46 REGULATORY CONSIDERATIONS IN APP

- Page 64 and 65:

48 REGULATORY CONSIDERATIONS IN APP

- Page 66 and 67: 50 REGULATORY CONSIDERATIONS IN APP

- Page 68 and 69: 52 REGULATORY CONSIDERATIONS IN APP

- Page 70 and 71: 54 REGULATORY CONSIDERATIONS IN APP

- Page 72 and 73: 56 REGULATORY CONSIDERATIONS IN APP

- Page 75 and 76: 1.3 RADIOPHARMACEUTICAL MANUFACTURI

- Page 77 and 78: The terms tracer, radiotracer , and

- Page 79 and 80: number of atoms that disintegrate d

- Page 81 and 82: images that can also give quantitat

- Page 83 and 84: PRODUCT DEVELOPMENT 67 Product Stab

- Page 85 and 86: MANUFACTURING ASPECTS 69 stations s

- Page 87 and 88: In general, the manufacturing of mo

- Page 89 and 90: MANUFACTURING ASPECTS 73 Production

- Page 91 and 92: PRODUCT MANUFACTURING 75 tainer. Th

- Page 93 and 94: PRODUCT MANUFACTURING 77 practical

- Page 95 and 96: PRODUCT MANUFACTURING 79 these radi

- Page 97 and 98: PRODUCT MANUFACTURING 81 Most of th

- Page 99 and 100: PRODUCT MANUFACTURING 83 PET Radiop

- Page 101 and 102: PRODUCT MANUFACTURING 85 FIGURE 5 S

- Page 103 and 104: PRODUCT MANUFACTURING 87 tions in t

- Page 105 and 106: QUALITY CONSIDERATIONS 89 regulatio

- Page 107 and 108: L1 L2 TC-MDP + Hydr. Tc TC-MDP + Tc

- Page 109 and 110: EXTEMPORANEOUS PREPARATION OF RADIO

- Page 111 and 112: Independent of which regulation app

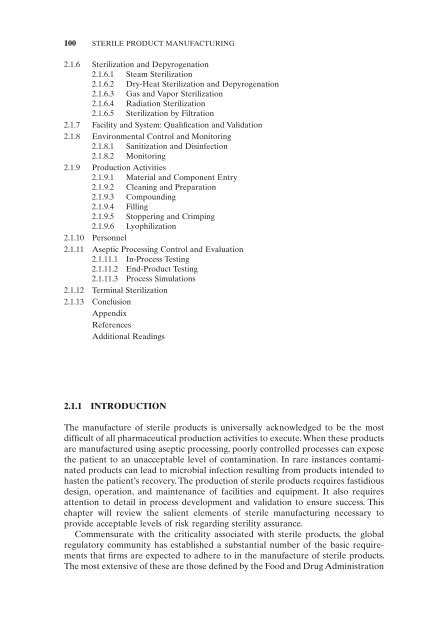

- Page 113: SECTION 2 ASEPTIC PROCESSING

- Page 118 and 119: 102 STERILE PRODUCT MANUFACTURING A

- Page 120 and 121: 104 STERILE PRODUCT MANUFACTURING T

- Page 122 and 123: 106 STERILE PRODUCT MANUFACTURING E

- Page 124 and 125: 108 STERILE PRODUCT MANUFACTURING I

- Page 126 and 127: 110 STERILE PRODUCT MANUFACTURING 2

- Page 128 and 129: 112 STERILE PRODUCT MANUFACTURING c

- Page 130 and 131: 114 STERILE PRODUCT MANUFACTURING 2

- Page 132 and 133: 116 STERILE PRODUCT MANUFACTURING 2

- Page 134 and 135: 118 STERILE PRODUCT MANUFACTURING i

- Page 136 and 137: 120 STERILE PRODUCT MANUFACTURING o

- Page 138 and 139: 122 STERILE PRODUCT MANUFACTURING a

- Page 140 and 141: 124 STERILE PRODUCT MANUFACTURING a

- Page 142 and 143: 126 STERILE PRODUCT MANUFACTURING e

- Page 144 and 145: 128 STERILE PRODUCT MANUFACTURING A

- Page 146 and 147: 130 STERILE PRODUCT MANUFACTURING 2

- Page 148 and 149: 132 STERILE PRODUCT MANUFACTURING p

- Page 150 and 151: 134 STERILE PRODUCT MANUFACTURING 2

- Page 153: SECTION 3 FACILITY

- Page 156 and 157: 140 EFFECT OF SCALE-UP ON OPERATION

- Page 158 and 159: 142 EFFECT OF SCALE-UP ON OPERATION

- Page 160 and 161: 144 EFFECT OF SCALE-UP ON OPERATION

- Page 162 and 163: 146 EFFECT OF SCALE-UP ON OPERATION

- Page 164 and 165: 148 EFFECT OF SCALE-UP ON OPERATION

- Page 166 and 167:

150 EFFECT OF SCALE-UP ON OPERATION

- Page 168 and 169:

152 EFFECT OF SCALE-UP ON OPERATION

- Page 170 and 171:

154 EFFECT OF SCALE-UP ON OPERATION

- Page 172 and 173:

156 EFFECT OF SCALE-UP ON OPERATION

- Page 174 and 175:

158 EFFECT OF SCALE-UP ON OPERATION

- Page 176 and 177:

160 PACKAGING AND LABELING 3.2.1 3.

- Page 178 and 179:

162 PACKAGING AND LABELING signifi

- Page 180 and 181:

164 PACKAGING AND LABELING Although

- Page 182 and 183:

166 PACKAGING AND LABELING componen

- Page 184 and 185:

168 PACKAGING AND LABELING sions. T

- Page 186 and 187:

170 PACKAGING AND LABELING TABLE 1

- Page 188 and 189:

172 PACKAGING AND LABELING the stab

- Page 190 and 191:

174 PACKAGING AND LABELING and accu

- Page 192 and 193:

176 PACKAGING AND LABELING The safe

- Page 194 and 195:

178 PACKAGING AND LABELING If the p

- Page 196 and 197:

180 PACKAGING AND LABELING exposure

- Page 198 and 199:

182 PACKAGING AND LABELING In many

- Page 200 and 201:

184 PACKAGING AND LABELING Nonpharm

- Page 202 and 203:

186 PACKAGING AND LABELING In 1906,

- Page 204 and 205:

188 PACKAGING AND LABELING A medica

- Page 206 and 207:

190 PACKAGING AND LABELING The inst

- Page 208 and 209:

192 PACKAGING AND LABELING the poun

- Page 210 and 211:

194 PACKAGING AND LABELING • (4)

- Page 212 and 213:

196 PACKAGING AND LABELING In the c

- Page 214 and 215:

198 PACKAGING AND LABELING • Inte

- Page 216 and 217:

200 PACKAGING AND LABELING 27. U.S.

- Page 218 and 219:

202 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 220 and 221:

204 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 222 and 223:

206 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 224 and 225:

208 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 226 and 227:

210 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 228 and 229:

212 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 230 and 231:

214 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 232 and 233:

216 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 234 and 235:

218 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 236 and 237:

220 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 238 and 239:

222 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 240 and 241:

224 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 242 and 243:

226 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 244 and 245:

228 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 246 and 247:

230 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 248 and 249:

232 CLEAN-FACILITY DESIGN, CONSTRUC

- Page 251 and 252:

4.1 SOLID DOSAGE FORMS Barbara R. C

- Page 253 and 254:

TABLE 2 Types of Solid Dosage Form

- Page 255 and 256:

(GI) tract or for systemic effects.

- Page 257 and 258:

EXCIPIENTS IN SOLID DOSE FORMULATIO

- Page 259 and 260:

EXCIPIENTS IN SOLID DOSE FORMULATIO

- Page 261 and 262:

HARD AND SOFT GELATIN CAPSULES 245

- Page 263 and 264:

HARD AND SOFT GELATIN CAPSULES 247

- Page 265 and 266:

HARD AND SOFT GELATIN CAPSULES 249

- Page 267 and 268:

participants from the FDA, industry

- Page 269 and 270:

in the mouth. Compressed lozenges (

- Page 271 and 272:

ittle fi lm, have no unpleasant tas

- Page 273 and 274:

CHEWING GUMS 257 4.1.10.2 Manufactu

- Page 275 and 276:

already dissolved in the saliva pri

- Page 277 and 278:

ORALLY DISINTEGRATING TABLETS 261 a

- Page 279 and 280:

tions. Some buccal formulations hav

- Page 281:

REFERENCES 265 32. Habib , W. , Kha

- Page 284 and 285:

268 SEMISOLID DOSAGES: OINTMENTS, C

- Page 286 and 287:

270 SEMISOLID DOSAGES: OINTMENTS, C

- Page 288 and 289:

272 SEMISOLID DOSAGES: OINTMENTS, C

- Page 290 and 291:

274 SEMISOLID DOSAGES: OINTMENTS, C

- Page 292 and 293:

276 SEMISOLID DOSAGES: OINTMENTS, C

- Page 294 and 295:

278 SEMISOLID DOSAGES: OINTMENTS, C

- Page 296 and 297:

280 SEMISOLID DOSAGES: OINTMENTS, C

- Page 298 and 299:

282 SEMISOLID DOSAGES: OINTMENTS, C

- Page 300 and 301:

284 SEMISOLID DOSAGES: OINTMENTS, C

- Page 302 and 303:

286 SEMISOLID DOSAGES: OINTMENTS, C

- Page 304 and 305:

288 SEMISOLID DOSAGES: OINTMENTS, C

- Page 306 and 307:

290 SEMISOLID DOSAGES: OINTMENTS, C

- Page 308 and 309:

292 SEMISOLID DOSAGES: OINTMENTS, C

- Page 310 and 311:

294 SEMISOLID DOSAGES: OINTMENTS, C

- Page 312 and 313:

296 SEMISOLID DOSAGES: OINTMENTS, C

- Page 314 and 315:

298 SEMISOLID DOSAGES: OINTMENTS, C

- Page 316 and 317:

300 SEMISOLID DOSAGES: OINTMENTS, C

- Page 318 and 319:

302 SEMISOLID DOSAGES: OINTMENTS, C

- Page 320 and 321:

304 SEMISOLID DOSAGES: OINTMENTS, C

- Page 322 and 323:

306 SEMISOLID DOSAGES: OINTMENTS, C

- Page 324 and 325:

308 SEMISOLID DOSAGES: OINTMENTS, C

- Page 326 and 327:

310 SEMISOLID DOSAGES: OINTMENTS, C

- Page 328 and 329:

312 SEMISOLID DOSAGES: OINTMENTS, C

- Page 330 and 331:

314 LIQUID DOSAGE FORMS 4.3.1 INTRO

- Page 332 and 333:

316 LIQUID DOSAGE FORMS 4.3.2 GENER

- Page 334 and 335:

318 LIQUID DOSAGE FORMS design, bui

- Page 336 and 337:

320 LIQUID DOSAGE FORMS tions with

- Page 338 and 339:

322 LIQUID DOSAGE FORMS Dosing Pump

- Page 340 and 341:

324 LIQUID DOSAGE FORMS However, th

- Page 342 and 343:

326 LIQUID DOSAGE FORMS Location of

- Page 344 and 345:

328 LIQUID DOSAGE FORMS Solid drugs

- Page 346 and 347:

330 LIQUID DOSAGE FORMS TABLE 3 Emu

- Page 348 and 349:

332 LIQUID DOSAGE FORMS Temperature

- Page 350 and 351:

334 LIQUID DOSAGE FORMS for viscosi

- Page 352 and 353:

336 LIQUID DOSAGE FORMS spectrum, s

- Page 354 and 355:

338 LIQUID DOSAGE FORMS Product Spe

- Page 356 and 357:

340 LIQUID DOSAGE FORMS Liquid, Ext

- Page 358 and 359:

342 LIQUID DOSAGE FORMS 7. Kourouna

- Page 360 and 361:

344 LIQUID DOSAGE FORMS 46. Miller

- Page 363 and 364:

5.1 CONTROLLED - RELEASE DOSAGE FOR

- Page 365 and 366:

CONTROLLED-RELEASE DRUG DELIVERY SY

- Page 367 and 368:

CONTROLLED-RELEASE FORMULATIONS 351

- Page 369 and 370:

dosage forms [12] . For example, or

- Page 371 and 372:

Degradation Liver Hydrolytic Enzyma

- Page 373 and 374:

CONTROLLED-RELEASE ORAL DOSAGE FORM

- Page 375 and 376:

DESIGN AND FABRICATION OF CONTROLLE

- Page 377 and 378:

DESIGN AND FABRICATION OF CONTROLLE

- Page 379 and 380:

DESIGN AND FABRICATION OF CONTROLLE

- Page 381 and 382:

DESIGN AND FABRICATION OF CONTROLLE

- Page 383 and 384:

TECHNOLOGIES FOR DEVELOPING TRANSDE

- Page 385 and 386:

TECHNOLOGIES FOR DEVELOPING TRANSDE

- Page 387 and 388:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 389 and 390:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 391 and 392:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 393 and 394:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 395 and 396:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 397 and 398:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 399 and 400:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 401 and 402:

RELEASE OF DRUGS FROM CONTROLLED-RE

- Page 403 and 404:

REFERENCES 387 16. Anal , A. K. ( 2

- Page 405 and 406:

REFERENCES 389 57. M ü ller , R. H

- Page 407 and 408:

REFERENCES 391 96. Sungthongjeen ,

- Page 409 and 410:

5.2 PROGRESS IN DESIGN OF BIODEGRAD

- Page 411 and 412:

INTRODUCTION 395 sequences. In addi

- Page 413 and 414:

TABLE 2 Injectable Peptide/Proteins

- Page 415 and 416:

PEPTIDE/PROTEIN-LOADED MICROSPHERE

- Page 417 and 418:

PEPTIDE/PROTEIN-LOADED MICROSPHERE

- Page 419 and 420:

PEPTIDE/PROTEIN-LOADED MICROSPHERE

- Page 421 and 422:

ANALYTICAL CHARACTERIZATION 405 imm

- Page 423 and 424:

IMMUNE SYSTEM INTERACTION WITH INJE

- Page 425 and 426:

INJECTABLE PEPTIDE/PROTEIN-LOADED M

- Page 427 and 428:

INJECTABLE PEPTIDE/PROTEIN-LOADED M

- Page 429 and 430:

INJECTABLE PEPTIDE/PROTEIN-LOADED M

- Page 431 and 432:

INJECTABLE PEPTIDE/PROTEIN-LOADED M

- Page 433 and 434:

INJECTABLE PEPTIDE/PROTEIN-LOADED M

- Page 435 and 436:

PEPTIDE/PROTEIN ENCAPSULATED INTO B

- Page 437 and 438:

PEPTIDE/PROTEIN ENCAPSULATED INTO B

- Page 439 and 440:

PEPTIDE/PROTEIN ENCAPSULATED INTO B

- Page 441 and 442:

PEPTIDE/PROTEIN ENCAPSULATED INTO B

- Page 443 and 444:

REFERENCES 427 novel ways to reduce

- Page 445 and 446:

REFERENCES 429 31. Morlock , M. , K

- Page 447 and 448:

REFERENCES 431 63. Lam , X. M. , Du

- Page 449 and 450:

REFERENCES 433 95. van de Weert , M

- Page 451 and 452:

REFERENCES 435 130. Bilati , U. , A

- Page 453 and 454:

REFERENCES 437 166. Means , G. E. ,

- Page 455 and 456:

REFERENCES 439 bic poly(lactide -co

- Page 457:

REFERENCES 441 237. Singh , M. , Li

- Page 460 and 461:

444 LIPOSOMES AND DRUG DELIVERY (sm

- Page 462 and 463:

446 LIPOSOMES AND DRUG DELIVERY Con

- Page 464 and 465:

448 LIPOSOMES AND DRUG DELIVERY and

- Page 466 and 467:

450 LIPOSOMES AND DRUG DELIVERY tec

- Page 468 and 469:

452 LIPOSOMES AND DRUG DELIVERY 250

- Page 470 and 471:

454 LIPOSOMES AND DRUG DELIVERY a s

- Page 472 and 473:

456 LIPOSOMES AND DRUG DELIVERY For

- Page 474 and 475:

458 LIPOSOMES AND DRUG DELIVERY con

- Page 476 and 477:

460 LIPOSOMES AND DRUG DELIVERY The

- Page 478 and 479:

462 LIPOSOMES AND DRUG DELIVERY in

- Page 480 and 481:

464 LIPOSOMES AND DRUG DELIVERY c a

- Page 482 and 483:

466 LIPOSOMES AND DRUG DELIVERY Eve

- Page 484 and 485:

468 LIPOSOMES AND DRUG DELIVERY inc

- Page 486 and 487:

470 LIPOSOMES AND DRUG DELIVERY wit

- Page 488 and 489:

472 LIPOSOMES AND DRUG DELIVERY i.v

- Page 490 and 491:

474 LIPOSOMES AND DRUG DELIVERY for

- Page 492 and 493:

476 LIPOSOMES AND DRUG DELIVERY bet

- Page 494 and 495:

478 LIPOSOMES AND DRUG DELIVERY cli

- Page 496 and 497:

480 LIPOSOMES AND DRUG DELIVERY lea

- Page 498 and 499:

482 LIPOSOMES AND DRUG DELIVERY Vag

- Page 500 and 501:

484 LIPOSOMES AND DRUG DELIVERY TAB

- Page 502 and 503:

486 LIPOSOMES AND DRUG DELIVERY thr

- Page 504 and 505:

488 LIPOSOMES AND DRUG DELIVERY TAB

- Page 506 and 507:

490 LIPOSOMES AND DRUG DELIVERY tar

- Page 508 and 509:

492 LIPOSOMES AND DRUG DELIVERY tha

- Page 510 and 511:

494 LIPOSOMES AND DRUG DELIVERY wit

- Page 512 and 513:

496 LIPOSOMES AND DRUG DELIVERY Pul

- Page 514 and 515:

498 LIPOSOMES AND DRUG DELIVERY whi

- Page 516 and 517:

500 LIPOSOMES AND DRUG DELIVERY Inc

- Page 518 and 519:

502 LIPOSOMES AND DRUG DELIVERY Per

- Page 520 and 521:

504 LIPOSOMES AND DRUG DELIVERY can

- Page 522 and 523:

506 LIPOSOMES AND DRUG DELIVERY Tum

- Page 524 and 525:

508 LIPOSOMES AND DRUG DELIVERY 25.

- Page 526 and 527:

510 LIPOSOMES AND DRUG DELIVERY 60.

- Page 528 and 529:

512 LIPOSOMES AND DRUG DELIVERY 97.

- Page 530 and 531:

514 LIPOSOMES AND DRUG DELIVERY 136

- Page 532 and 533:

516 LIPOSOMES AND DRUG DELIVERY 170

- Page 534 and 535:

518 LIPOSOMES AND DRUG DELIVERY 202

- Page 536 and 537:

520 LIPOSOMES AND DRUG DELIVERY 237

- Page 538 and 539:

522 LIPOSOMES AND DRUG DELIVERY 271

- Page 540 and 541:

524 LIPOSOMES AND DRUG DELIVERY 310

- Page 542 and 543:

526 LIPOSOMES AND DRUG DELIVERY 346

- Page 544 and 545:

528 LIPOSOMES AND DRUG DELIVERY 378

- Page 546 and 547:

530 LIPOSOMES AND DRUG DELIVERY 408

- Page 548 and 549:

532 LIPOSOMES AND DRUG DELIVERY 437

- Page 551 and 552:

5.4 BIODEGRADABLE NANOPARTICLES Sud

- Page 553 and 554:

NATURAL BIODEGRADABLE POLYMERIC NAN

- Page 555 and 556:

NATURAL BIODEGRADABLE POLYMERIC NAN

- Page 557 and 558:

NATURAL BIODEGRADABLE POLYMERIC NAN

- Page 559 and 560:

and drug loading of gliadin nanopar

- Page 561 and 562:

SYNTHETIC BIODEGRADABLE POLYMERIC N

- Page 563 and 564:

APPLICATIONS OF BIODEGRADABLE NANOP

- Page 565 and 566:

PHYSICOCHEMICAL CHARACTERIZATION OF

- Page 567 and 568:

TARGETING NANOPARTICLES BY SURFACE

- Page 569 and 570:

5.4.9 CONCLUSIONS Biodegradable nan

- Page 571 and 572:

REFERENCES 555 of a model protein (

- Page 573 and 574:

REFERENCES 557 65. Kaul , G. , and

- Page 575 and 576:

REFERENCES 559 99. Carino , G. P. ,

- Page 577 and 578:

REFERENCES 561 133. Na , K. , Lee ,

- Page 579 and 580:

REFERENCES 563 168. Freitas , C. ,

- Page 581 and 582:

5.5 RECOMBINANT SACCHAROMYCES CEREV

- Page 583 and 584:

Potential Medical Applications of B

- Page 585 and 586:

BIODRUG CONCEPT USING YEAST AS VECT

- Page 587 and 588:

BIODRUG CONCEPT USING YEAST AS VECT

- Page 589 and 590:

Cumulative ileal delivery of viable

- Page 591 and 592:

tine [30] . No signal was detectabl

- Page 593 and 594:

ORAL FORMULATION OF RECOMBINANT YEA

- Page 595 and 596:

Cumulative ileal delivery of viable

- Page 597 and 598:

ORAL FORMULATION OF RECOMBINANT YEA

- Page 599 and 600:

Viable yeasts released (% of initia

- Page 601 and 602:

Steidler et al. [47] have already d

- Page 603 and 604:

REFERENCES 587 23. Steidler , L. (

- Page 605 and 606:

REFERENCES 589 nant yeasts as novel

- Page 607 and 608:

5.6 NASAL DELIVERY OF PEPTIDE AND N

- Page 609 and 610:

fi rst - pass metabolism and gut -

- Page 611 and 612:

[6] . The nasal blood vessels can b

- Page 613 and 614:

FACTORS INFLUENCING NASAL DRUG ABSO

- Page 615 and 616:

5.6.3.6 Type of Delivery Device FAC

- Page 617 and 618:

FACTORS INFLUENCING NASAL DRUG ABSO

- Page 619 and 620:

FIGURE 4 ( a ) Optinose multidose l

- Page 621 and 622:

Dogs, sheep, and monkeys can be kep

- Page 623 and 624:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 625 and 626:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 627 and 628:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 629 and 630:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 631 and 632:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 633 and 634:

in solutions containing different c

- Page 635 and 636:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 637 and 638:

NASAL DELIVERY OF PEPTIDE AND HIGH-

- Page 639 and 640:

Morphine plasma concentration (nmol

- Page 641 and 642:

Concentration (μg/L) 1000 100 10 1

- Page 643 and 644:

NASAL DELIVERY OF NONPEPTIDE MOLECU

- Page 645 and 646:

NASAL DELIVERY OF NONPEPTIDE MOLECU

- Page 647 and 648:

OPTION FOR DELIVERY OF DRUGS TO CEN

- Page 649 and 650:

pseudostratifi ed epithelium compri

- Page 651 and 652:

NASAL DELIVERY OF VACCINES 635 Howe

- Page 653 and 654:

TABLE 5 Continued Delivery System/A

- Page 655 and 656:

REFERENCES 639 23. Hardy , J. G. ,

- Page 657 and 658:

REFERENCES 641 60. Collens , W. S.

- Page 659 and 660:

REFERENCES 643 97. Eden , S. ( 1979

- Page 661 and 662:

REFERENCES 645 comparison with oral

- Page 663 and 664:

REFERENCES 647 172. Sakane , T. , A

- Page 665 and 666:

REFERENCES 649 213. McCluskie , M.

- Page 667 and 668:

5.7 NASAL POWDER DRUG DELIVERY Jele

- Page 669 and 670:

NASAL DRY POWDER FORMULATIONS 653 t

- Page 671 and 672:

POLYMERS IN NASAL POWDER DELIVERY S

- Page 673 and 674:

POLYMERS IN NASAL POWDER DELIVERY S

- Page 675 and 676:

MICROSPHERES AS NASAL DRUG DELIVERY

- Page 677 and 678:

MICROSPHERES AS NASAL DRUG DELIVERY

- Page 679 and 680:

MICROSPHERES AS NASAL DRUG DELIVERY

- Page 681 and 682:

MICROSPHERES AS NASAL DRUG DELIVERY

- Page 683 and 684:

TOXICOLOGICAL CONSIDERATIONS 667 et

- Page 685 and 686:

Summary of Research Work on Nasal D

- Page 687 and 688:

Powder Formulation Preparation Meth

- Page 689 and 690:

Powder Formulation Preparation Meth

- Page 691 and 692:

REFERENCES 675 19. Van der Lubben ,

- Page 693 and 694:

REFERENCES 677 54. Witschi , C. , a

- Page 695 and 696:

REFERENCES 679 91. Varshosaz , J. ,

- Page 697:

REFERENCES 681 126. Jorissen , M. ,

- Page 700 and 701:

684 AEROSOL DRUG DELIVERY 5.8.8 5.8

- Page 702 and 703:

686 AEROSOL DRUG DELIVERY other sig

- Page 704 and 705:

688 AEROSOL DRUG DELIVERY are a num

- Page 706 and 707:

690 AEROSOL DRUG DELIVERY 5.8.5 MET

- Page 708 and 709:

692 AEROSOL DRUG DELIVERY TABLE 1 S

- Page 710 and 711:

694 AEROSOL DRUG DELIVERY valve siz

- Page 712 and 713:

696 AEROSOL DRUG DELIVERY Ferrule U

- Page 714 and 715:

698 AEROSOL DRUG DELIVERY 5.8.5.6 A

- Page 716 and 717:

700 AEROSOL DRUG DELIVERY 5.8.5.10

- Page 718 and 719:

702 AEROSOL DRUG DELIVERY low inter

- Page 720 and 721:

704 AEROSOL DRUG DELIVERY Transpare

- Page 722 and 723:

706 AEROSOL DRUG DELIVERY of the cl

- Page 724 and 725:

708 AEROSOL DRUG DELIVERY is achiev

- Page 726 and 727:

710 AEROSOL DRUG DELIVERY Aerosol g

- Page 728 and 729:

712 AEROSOL DRUG DELIVERY REFERENCE

- Page 730 and 731:

714 AEROSOL DRUG DELIVERY 42. Witek

- Page 732 and 733:

716 AEROSOL DRUG DELIVERY 81. Ohmor

- Page 734 and 735:

718 AEROSOL DRUG DELIVERY 119. Lewi

- Page 736 and 737:

720 AEROSOL DRUG DELIVERY 153. Terz

- Page 738 and 739:

722 AEROSOL DRUG DELIVERY 189. Sham

- Page 740 and 741:

724 AEROSOL DRUG DELIVERY 225. Newh

- Page 742 and 743:

726 AEROSOL DRUG DELIVERY 263. Dolo

- Page 745 and 746:

5.9 OCULAR DRUG DELIVERY Ilva D. Ru

- Page 747 and 748:

CHALLENGES IN OCULAR DRUG DELIVERY

- Page 749 and 750:

CHALLENGES IN OCULAR DRUG DELIVERY

- Page 751 and 752:

CHALLENGES IN OCULAR DRUG DELIVERY

- Page 753 and 754:

FORMULATION APPROACHES TO IMPROVE O

- Page 755 and 756:

FORMULATION APPROACHES TO IMPROVE O

- Page 757 and 758:

Drug Fluorescein FORMULATION APPROA

- Page 759 and 760:

FORMULATION APPROACHES TO IMPROVE O

- Page 761 and 762:

FORMULATION APPROACHES TO IMPROVE O

- Page 763 and 764:

FORMULATION APPROACHES TO IMPROVE O

- Page 765 and 766:

FORMULATION APPROACHES TO IMPROVE O

- Page 767 and 768:

FORMULATION APPROACHES TO IMPROVE O

- Page 769 and 770:

is characterized by a transient ove

- Page 771 and 772:

REFERENCES 755 11. Klyce , S. D. ,

- Page 773 and 774:

REFERENCES 757 53. Saettone , M. F.

- Page 775 and 776:

REFERENCES 759 87. Lin , H. R. , an

- Page 777 and 778:

REFERENCES 761 122. Durrani , A. M.

- Page 779 and 780:

REFERENCES 763 158. Weyenberg , W.

- Page 781 and 782:

REFERENCES 765 of various ophthalmi

- Page 783:

REFERENCES 767 233. Grass , G. M. ,

- Page 786 and 787:

770 MICROEMULSIONS AS DRUG DELIVERY

- Page 788 and 789:

772 MICROEMULSIONS AS DRUG DELIVERY

- Page 790 and 791:

774 MICROEMULSIONS AS DRUG DELIVERY

- Page 792 and 793:

776 MICROEMULSIONS AS DRUG DELIVERY

- Page 794 and 795:

778 MICROEMULSIONS AS DRUG DELIVERY

- Page 796 and 797:

780 MICROEMULSIONS AS DRUG DELIVERY

- Page 798 and 799:

782 MICROEMULSIONS AS DRUG DELIVERY

- Page 800 and 801:

784 MICROEMULSIONS AS DRUG DELIVERY

- Page 802 and 803:

786 MICROEMULSIONS AS DRUG DELIVERY

- Page 804 and 805:

788 MICROEMULSIONS AS DRUG DELIVERY

- Page 806 and 807:

790 MICROEMULSIONS AS DRUG DELIVERY

- Page 808 and 809:

792 MICROEMULSIONS AS DRUG DELIVERY

- Page 810 and 811:

794 TRANSDERMAL DRUG DELIVERY 5.11.

- Page 812 and 813:

796 TRANSDERMAL DRUG DELIVERY conta

- Page 814 and 815:

798 TRANSDERMAL DRUG DELIVERY 5.11.

- Page 816 and 817:

800 TRANSDERMAL DRUG DELIVERY FIGUR

- Page 818 and 819:

802 TRANSDERMAL DRUG DELIVERY a rat

- Page 820 and 821:

804 TRANSDERMAL DRUG DELIVERY passi

- Page 822 and 823:

806 TRANSDERMAL DRUG DELIVERY 19. E

- Page 825 and 826:

5.12 VAGINAL DRUG DELIVERY Jos é d

- Page 827 and 828:

Therefore, this chapter discusses t

- Page 829 and 830:

THE HUMAN VAGINA 813 thetic innerva

- Page 831 and 832:

THE HUMAN VAGINA 815 the upper repr

- Page 833 and 834:

THE HUMAN VAGINA 817 tant in the re

- Page 835 and 836:

GENERAL FEATURES OF VAGINAL DRUG DE

- Page 837 and 838:

Although this strategy may enhance

- Page 839 and 840:

VAGINAL DRUG DELIVERY SYSTEMS 823 a

- Page 841 and 842:

VAGINAL DRUG DELIVERY SYSTEMS 825 f

- Page 843 and 844:

VAGINAL DRUG DELIVERY SYSTEMS 827 f

- Page 845 and 846:

Amount released, μg/day 800 700 60

- Page 847 and 848:

VAGINAL DRUG DELIVERY SYSTEMS 831 5

- Page 849 and 850:

TABLE 4 Examples of Mucoadhesive Po

- Page 851 and 852:

VAGINAL DRUG DELIVERY SYSTEMS 835 i

- Page 853 and 854:

PHARMACEUTICAL EVALUATION OF VAGINA

- Page 855 and 856:

PHARMACEUTICAL EVALUATION OF VAGINA

- Page 857 and 858:

PHARMACEUTICAL EVALUATION OF VAGINA

- Page 859 and 860:

CLINICAL USAGE AND POTENTIAL OF VAG

- Page 861 and 862:

CLINICAL USAGE AND POTENTIAL OF VAG

- Page 863 and 864:

CLINICAL USAGE AND POTENTIAL OF VAG

- Page 865 and 866:

CLINICAL USAGE AND POTENTIAL OF VAG

- Page 867 and 868:

CLINICAL USAGE AND POTENTIAL OF VAG

- Page 869 and 870:

TABLE 6 Selected Drugs Administered

- Page 871 and 872:

Selected Veterinary Vaginal Drug De

- Page 873 and 874:

REFERENCES 857 Much work remains to

- Page 875 and 876:

REFERENCES 859 33. Hocini , H. , Ba

- Page 877 and 878:

REFERENCES 861 70. Kristmundsdottir

- Page 879 and 880:

REFERENCES 863 105. McClelland , R.

- Page 881 and 882:

REFERENCES 865 141. Kuyoh , M. A. ,

- Page 883 and 884:

REFERENCES 867 178. Ondracek , J. ,

- Page 885 and 886:

REFERENCES 869 212. Bagga , R. , Ra

- Page 887 and 888:

REFERENCES 871 244. International W

- Page 889 and 890:

REFERENCES 873 276. Mor , E. , Saad

- Page 891 and 892:

REFERENCES 875 310. Saltzman , W. M

- Page 893 and 894:

REFERENCES 877 vaginal microbicides

- Page 895:

SECTION 6 TABLET PRODUCTION

- Page 898 and 899:

882 PHARMACEUTICAL PREFORMULATION 6

- Page 900 and 901:

884 PHARMACEUTICAL PREFORMULATION E

- Page 902 and 903:

886 PHARMACEUTICAL PREFORMULATION T

- Page 904 and 905:

888 PHARMACEUTICAL PREFORMULATION T

- Page 906 and 907:

890 PHARMACEUTICAL PREFORMULATION T

- Page 908 and 909:

892 PHARMACEUTICAL PREFORMULATION p

- Page 910 and 911:

894 PHARMACEUTICAL PREFORMULATION T

- Page 912 and 913:

896 PHARMACEUTICAL PREFORMULATION T

- Page 914 and 915:

898 PHARMACEUTICAL PREFORMULATION l

- Page 916 and 917:

900 PHARMACEUTICAL PREFORMULATION T

- Page 918 and 919:

902 PHARMACEUTICAL PREFORMULATION s

- Page 920 and 921:

904 PHARMACEUTICAL PREFORMULATION C

- Page 922 and 923:

906 PHARMACEUTICAL PREFORMULATION p

- Page 924 and 925:

908 PHARMACEUTICAL PREFORMULATION C

- Page 926 and 927:

910 PHARMACEUTICAL PREFORMULATION T

- Page 928 and 929:

912 PHARMACEUTICAL PREFORMULATION D

- Page 930 and 931:

914 PHARMACEUTICAL PREFORMULATION C

- Page 932 and 933:

916 PHARMACEUTICAL PREFORMULATION u

- Page 934 and 935:

918 PHARMACEUTICAL PREFORMULATION d

- Page 936 and 937:

920 PHARMACEUTICAL PREFORMULATION q

- Page 938 and 939:

922 PHARMACEUTICAL PREFORMULATION w

- Page 940 and 941:

924 PHARMACEUTICAL PREFORMULATION C

- Page 942 and 943:

926 PHARMACEUTICAL PREFORMULATION T

- Page 944 and 945:

928 PHARMACEUTICAL PREFORMULATION a

- Page 946 and 947:

930 PHARMACEUTICAL PREFORMULATION a

- Page 949 and 950:

6.2 ROLE OF PREFORMULATION IN DEVEL

- Page 951 and 952:

maceutics ” documentation forms a

- Page 953 and 954:

e altered without any change in the

- Page 955 and 956:

Solubility Heat flow II I T m,II Ts

- Page 957 and 958:

TABLE 2 Techniques to Characterize

- Page 959 and 960:

Percent weight loss Heat flow (a) (

- Page 961 and 962:

Heat flow Intensity 100 50 Endother

- Page 963 and 964:

Change in mass (%) PHYSICAL/BULK CH

- Page 965 and 966:

6.2.2.6 Powder Flow and Compressibi

- Page 967 and 968:

Solvent required for 1 gm of solid

- Page 969 and 970:

⎧ 100 ⎪ Ka 1+10 Percent ionized

- Page 971 and 972:

Percent Ionization Percent Ionizati

- Page 973 and 974:

SOLUBILITY CHARACTERISTICS 957 para

- Page 975 and 976:

SOLUBILITY CHARACTERISTICS 959 of p

- Page 977 and 978:

Dissolution studies pH solubility p

- Page 979 and 980:

High Permeability Low SOLUBILITY CH

- Page 981 and 982:

is evident form the fact [51] that

- Page 983 and 984:

independent of initial drug concent

- Page 985 and 986:

STABILITY CHARACTERISTICS 969 drug

- Page 987 and 988:

6.2.5 CONCLUSIONS Preformulation te

- Page 989 and 990:

REFERENCES 973 16. Huang , L. , and

- Page 991:

54. 55. 56. REFERENCES 975 IFAMA (

- Page 994 and 995:

978 TABLET DESIGN 6.3.9.3 Case Stud

- Page 996 and 997:

980 TABLET DESIGN Another reason, t

- Page 998 and 999:

982 TABLET DESIGN E: This ensures t

- Page 1000 and 1001:

984 TABLET DESIGN substance would b

- Page 1002 and 1003:

986 TABLET DESIGN Plasticity 1.0 0.

- Page 1004 and 1005:

988 TABLET DESIGN Drug release (%)

- Page 1006 and 1007:

990 TABLET DESIGN FIGURE 9 Dissolut

- Page 1008 and 1009:

992 TABLET DESIGN TABLE 2 Number 1

- Page 1010 and 1011:

994 TABLET DESIGN Formulation Table

- Page 1012 and 1013:

996 TABLET DESIGN TABLE 4 Theophyll

- Page 1014 and 1015:

998 TABLET DESIGN often very fi ne,

- Page 1016 and 1017:

1000 TABLE 6 Formulations by Wet Gr

- Page 1018 and 1019:

1002 TABLET DESIGN 6.3.6.2 FIGURE 1

- Page 1020 and 1021:

1004 TABLET DESIGN TABLE 9 Papaveri

- Page 1022 and 1023:

1006 TABLET DESIGN TABLE 12 Weight

- Page 1024 and 1025:

1008 TABLET DESIGN (3.179 and 4.500

- Page 1026 and 1027:

1010 TABLET DESIGN TABLE 14 Run Ord

- Page 1028 and 1029:

1012 TABLET DESIGN Regression coeff

- Page 1030 and 1031:

1014 TABLET DESIGN to being the out

- Page 1032 and 1033:

1016 TABLET DESIGN Mechanical Prope

- Page 1034 and 1035:

1018 TABLET DESIGN drawbacks (unsaf

- Page 1036 and 1037:

1020 TABLET DESIGN TABLE 16 Basic F

- Page 1038 and 1039:

1022 TABLET DESIGN PEG (e.g., Macro

- Page 1040 and 1041:

1024 TABLET DESIGN 0.45% 0.40% 0.35

- Page 1042 and 1043:

1026 TABLET DESIGN FIGURE 34 Granul

- Page 1044 and 1045:

1028 TABLET DESIGN TABLE 19 SEPIFIL

- Page 1046 and 1047:

1030 TABLET DESIGN (c) Blistering D

- Page 1048 and 1049:

1032 TABLET DESIGN % Dextromethorph

- Page 1050 and 1051:

1034 TABLET DESIGN (a) (b) 500 μm

- Page 1052 and 1053:

1036 TABLET DESIGN threshold p c1 a

- Page 1054 and 1055:

1038 TABLET DESIGN TABLE 24 Composi

- Page 1056 and 1057:

1040 TABLET DESIGN Korsmeyer - Pepp

- Page 1058 and 1059:

1042 TABLET DESIGN % Water uptake/d

- Page 1060 and 1061:

1044 TABLET DESIGN FIGURE 47 Temper

- Page 1062 and 1063:

1046 TABLET DESIGN REFERENCES 1. Un

- Page 1064 and 1065:

1048 TABLET DESIGN 34. Congreve , M

- Page 1066 and 1067:

1050 TABLET DESIGN 73. Miranda , A.

- Page 1069 and 1070:

6.4 TABLET PRODUCTION SYSTEMS Katha

- Page 1071 and 1072:

PHYSICS OF TABLET FORMATION 1055 en

- Page 1073 and 1074:

Tablet production systems can be op

- Page 1075 and 1076:

TABLETING MACHINES 1059 Eccentric T

- Page 1077 and 1078:

TABLETING MACHINES 1061 In Figure 4

- Page 1079 and 1080:

TABLETING MACHINE SIMULATORS (COMPA

- Page 1081 and 1082:

TABLETING MACHINE SIMULATORS (COMPA

- Page 1083 and 1084:

However, for mechanical compaction

- Page 1085 and 1086:

INSTRUMENTATION OF TABLETING MACHIN

- Page 1087 and 1088:

Force (kN) FIGURE 13 ANALYSIS OF TA

- Page 1089 and 1090:

TABLE 4 Source Emschermann [91] (Fi

- Page 1091 and 1092:

TABLE 6 Parameters Directly Deduced

- Page 1093 and 1094:

TABLE 7 Parameters Calculated from

- Page 1095 and 1096:

ANALYSIS OF TABLETING PROCESS 1079

- Page 1097 and 1098:

TABLE 8 Source 3D model [143, 144,

- Page 1099 and 1100:

6.4.11 SPECIAL ACCESSORIES OF TABLE

- Page 1101 and 1102:

usually tends to vary. However, the

- Page 1103 and 1104:

ing at punches and dies. Low produc

- Page 1105 and 1106:

REFERENCES 1089 24. Elamin , A. , S

- Page 1107 and 1108:

REFERENCES 1091 64. Yeh , C. , Alta

- Page 1109 and 1110:

REFERENCES 1093 100. Armstrong , N.

- Page 1111 and 1112:

REFERENCES 1095 140. Kuentz , M. ,

- Page 1113 and 1114:

REFERENCES 1097 178. Hauschild , K.

- Page 1115 and 1116:

6.5 CONTROLLED RELEASE OF DRUGS FRO

- Page 1117 and 1118:

INTRODUCTION 1101 ings, and their e

- Page 1119 and 1120:

needed to circulate them [57] . Typ

- Page 1121 and 1122:

APPLICATIONS 1105 stream. During dr

- Page 1123 and 1124:

APPLICATIONS 1107 TABLE 1 Theophyll

- Page 1125 and 1126:

APPLICATIONS 1109 FIGURE 1 Release

- Page 1127 and 1128:

(a) (b) APPLICATIONS 1111 FIGURE 3

- Page 1129 and 1130:

APPLICATIONS 1113 FIGURE 5 Ternary

- Page 1131 and 1132:

APPLICATIONS 1115 of the drug, dC/d

- Page 1133 and 1134:

APPLICATIONS 1117 FIGURE 9 Ternary

- Page 1135 and 1136:

Release rate (mg/min) 0.40 0.30 0.2

- Page 1137 and 1138:

REFERENCES REFERENCES 1121 1. Lange

- Page 1139 and 1140:

REFERENCES 1123 37. Lin , Y - K. ,

- Page 1141 and 1142:

REFERENCES 1125 73. St - Onge , L.

- Page 1143 and 1144:

REFERENCES 1127 107. Lai , J. - Y.

- Page 1145 and 1146:

APPENDIX 1129 FIGURE A3 Release of

- Page 1147 and 1148:

APPENDIX 1131 FIGURE A7 Release of

- Page 1149 and 1150:

6.6 TABLET COMPRESSION Helton M. M.

- Page 1151 and 1152:

during compression, which will also

- Page 1153 and 1154:

of powder mixtures is usually chara

- Page 1155 and 1156:

lose in combination with either tal

- Page 1157 and 1158:

Due to the signifi cant nonlinearit

- Page 1159 and 1160:

EQUIPMENT FOR TABLET COMPRESSION 11

- Page 1161 and 1162:

Product Fill cam (mm) column height

- Page 1163 and 1164:

TABLET PRESS TOOLING 1147 TABLE 1 T

- Page 1165 and 1166:

TABLET PRESS TOOLING 1149 7. Tungst

- Page 1167 and 1168:

FIGURE 6 Tooling standards confi gu

- Page 1169 and 1170:

6.6.7 TABLE ENGRAVING Engraving is

- Page 1171 and 1172:

Shallow and standard concave tablet

- Page 1173 and 1174:

is the most popular bisect confi gu

- Page 1175 and 1176:

PROBLEMS DURING TABLET MANUFACTURIN

- Page 1177 and 1178:

thus reducing a potential variation

- Page 1179:

REFERENCES 1163 27. Train , D. ( 19

- Page 1182 and 1183:

1166 EFFECTS OF GRINDING IN PHARMAC

- Page 1184 and 1185:

1168 EFFECTS OF GRINDING IN PHARMAC

- Page 1186 and 1187:

1170 EFFECTS OF GRINDING IN PHARMAC

- Page 1188 and 1189:

1172 EFFECTS OF GRINDING IN PHARMAC

- Page 1190 and 1191:

1174 EFFECTS OF GRINDING IN PHARMAC

- Page 1192 and 1193:

1176 EFFECTS OF GRINDING IN PHARMAC

- Page 1194 and 1195:

1178 EFFECTS OF GRINDING IN PHARMAC

- Page 1196 and 1197:

1180 EFFECTS OF GRINDING IN PHARMAC

- Page 1198 and 1199:

1182 EFFECTS OF GRINDING IN PHARMAC

- Page 1200 and 1201:

1184 EFFECTS OF GRINDING IN PHARMAC

- Page 1202 and 1203:

1186 EFFECTS OF GRINDING IN PHARMAC

- Page 1204 and 1205:

1188 EFFECTS OF GRINDING IN PHARMAC

- Page 1206 and 1207:

1190 EFFECTS OF GRINDING IN PHARMAC

- Page 1208 and 1209:

1192 ORAL EXTENDED-RELEASE FORMULAT

- Page 1210 and 1211:

1194 ORAL EXTENDED-RELEASE FORMULAT

- Page 1212 and 1213:

1196 ORAL EXTENDED-RELEASE FORMULAT

- Page 1214 and 1215:

1198 ORAL EXTENDED-RELEASE FORMULAT

- Page 1216 and 1217:

1200 ORAL EXTENDED-RELEASE FORMULAT

- Page 1218 and 1219:

1202 ORAL EXTENDED-RELEASE FORMULAT

- Page 1220 and 1221:

1204 ORAL EXTENDED-RELEASE FORMULAT

- Page 1222 and 1223:

1206 ORAL EXTENDED-RELEASE FORMULAT

- Page 1224 and 1225:

1208 ORAL EXTENDED-RELEASE FORMULAT

- Page 1226 and 1227:

1210 ORAL EXTENDED-RELEASE FORMULAT

- Page 1228 and 1229:

1212 ORAL EXTENDED-RELEASE FORMULAT

- Page 1230 and 1231:

1214 ORAL EXTENDED-RELEASE FORMULAT

- Page 1232 and 1233:

1216 ORAL EXTENDED-RELEASE FORMULAT

- Page 1234 and 1235:

1218 ORAL EXTENDED-RELEASE FORMULAT

- Page 1236 and 1237:

1220 ORAL EXTENDED-RELEASE FORMULAT

- Page 1238 and 1239:

1222 ORAL EXTENDED-RELEASE FORMULAT

- Page 1241 and 1242:

7.1 CYCLODEXTRIN - BASED NANOMATERI

- Page 1243 and 1244:

OH (3) OH (2) HOCH 2 HOCH 2 O O OH

- Page 1245 and 1246:

APPLICATIONS OF CYCLODEXTRINS IN NA

- Page 1247 and 1248:

Percentage of release 100 90 80 70

- Page 1249 and 1250:

APPLICATIONS OF CYCLODEXTRINS IN NA

- Page 1251 and 1252:

APPLICATIONS OF CYCLODEXTRINS IN NA

- Page 1253 and 1254:

APPLICATIONS OF CYCLODEXTRINS IN NA

- Page 1255 and 1256:

O APPLICATIONS OF CYCLODEXTRINS IN

- Page 1257 and 1258:

β - CDC6 loaded with the model dru

- Page 1259 and 1260:

REFERENCES 1243 13. Stella , V. J.

- Page 1261 and 1262:

REFERENCES 1245 49. Dodziuk , H. ,

- Page 1263:

REFERENCES 1247 81. Memi şo ğlu -

- Page 1266 and 1267:

1250 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1268 and 1269:

1252 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1270 and 1271:

1254 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1272 and 1273:

1256 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1274 and 1275:

1258 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1276 and 1277:

1260 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1278 and 1279:

1262 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1280 and 1281:

1264 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1282 and 1283:

1266 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1284 and 1285:

1268 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1286 and 1287:

1270 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1288 and 1289:

1272 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1290 and 1291:

1274 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1292 and 1293:

1276 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1294 and 1295:

1278 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1296 and 1297:

1280 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1298 and 1299:

1282 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1300 and 1301:

1284 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1302 and 1303:

1286 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1304 and 1305:

1288 NANOTECHNOLOGY IN PHARMACEUTIC

- Page 1306 and 1307:

1290 PHARMACEUTICAL NANOSYSTEMS 7.3

- Page 1308 and 1309:

1292 PHARMACEUTICAL NANOSYSTEMS TAB

- Page 1310 and 1311:

1294 PHARMACEUTICAL NANOSYSTEMS TAB

- Page 1312 and 1313:

1296 PHARMACEUTICAL NANOSYSTEMS Lam

- Page 1314 and 1315:

1298 PHARMACEUTICAL NANOSYSTEMS 7.3

- Page 1316 and 1317:

1300 PHARMACEUTICAL NANOSYSTEMS sta

- Page 1318 and 1319:

1302 PHARMACEUTICAL NANOSYSTEMS TAB

- Page 1320 and 1321:

1304 PHARMACEUTICAL NANOSYSTEMS har

- Page 1322 and 1323:

1306 PHARMACEUTICAL NANOSYSTEMS TAB

- Page 1324 and 1325:

1308 PHARMACEUTICAL NANOSYSTEMS Sur

- Page 1326 and 1327:

1310 PHARMACEUTICAL NANOSYSTEMS Aut

- Page 1328 and 1329:

1312 PHARMACEUTICAL NANOSYSTEMS ®

- Page 1330 and 1331:

1314 PHARMACEUTICAL NANOSYSTEMS 55.

- Page 1332 and 1333:

1316 PHARMACEUTICAL NANOSYSTEMS 100

- Page 1334 and 1335:

1318 PHARMACEUTICAL NANOSYSTEMS 147

- Page 1336 and 1337:

1320 PHARMACEUTICAL NANOSYSTEMS 191

- Page 1338 and 1339:

1322 PHARMACEUTICAL NANOSYSTEMS 230

- Page 1340 and 1341:

1324 PHARMACEUTICAL NANOSYSTEMS Nan

- Page 1343 and 1344:

7.4 OIL - IN - WATER NANOSIZED EMUL

- Page 1345 and 1346:

GENERATIONS OF OIL-IN-WATER NANOSIZ

- Page 1347 and 1348:

GENERATIONS OF OIL-IN-WATER NANOSIZ

- Page 1349 and 1350:

GENERATIONS OF OIL-IN-WATER NANOSIZ

- Page 1351 and 1352:

GENERATIONS OF OIL-IN-WATER NANOSIZ

- Page 1353 and 1354:

GENERATIONS OF OIL-IN-WATER NANOSIZ

- Page 1355 and 1356:

GENERATIONS OF OIL-IN-WATER NANOSIZ

- Page 1357 and 1358:

DRUG-FREE/LOADED OIL-IN-WATER NANOS

- Page 1359 and 1360:

EXCIPIENT INCLUSION: OIL-IN-WATER N

- Page 1361 and 1362:

EXCIPIENT INCLUSION: OIL-IN-WATER N

- Page 1363 and 1364:

MEDICAL APPLICATIONS OF OIL-IN-WATE

- Page 1365 and 1366:

MEDICAL APPLICATIONS OF OIL-IN-WATE

- Page 1367 and 1368:

MEDICAL APPLICATIONS OF OIL-IN-WATE

- Page 1369 and 1370:

MEDICAL APPLICATIONS OF OIL-IN-WATE

- Page 1371 and 1372:

evaluation of the lipid hydroperoxi

- Page 1373 and 1374:

REFERENCES 1357 21. Ott , G. , Sing

- Page 1375 and 1376:

REFERENCES 1359 57. Harris , J. M.

- Page 1377 and 1378:

REFERENCES 1361 94. Kim , Y. J. , K

- Page 1379 and 1380:

REFERENCES 1363 131. Swietlikowska

- Page 1381 and 1382:

REFERENCES 1365 167. Acheampong , A

- Page 1383 and 1384:

INDEX Abortifacients, 850 Acyclovir

- Page 1385 and 1386:

Lung cancer, 497-502 Lung toxicity,