Metal Foams: A Design Guide

Metal Foams: A Design Guide

Metal Foams: A Design Guide

- TAGS

- upload.vnuki.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

122 <strong>Metal</strong> <strong>Foams</strong>: A <strong>Design</strong> <strong>Guide</strong><br />

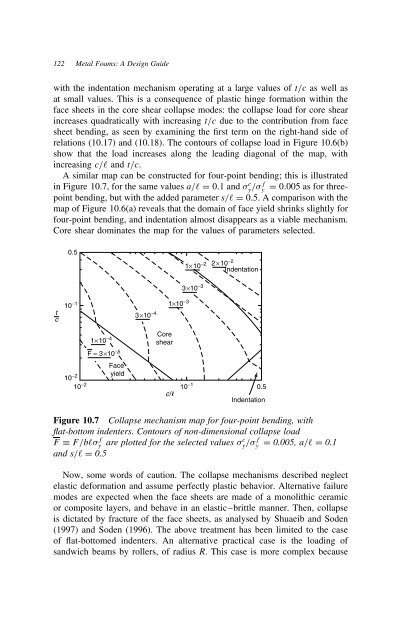

with the indentation mechanism operating at a large values of t/c as well as<br />

at small values. This is a consequence of plastic hinge formation within the<br />

face sheets in the core shear collapse modes: the collapse load for core shear<br />

increases quadratically with increasing t/c due to the contribution from face<br />

sheet bending, as seen by examining the first term on the right-hand side of<br />

relations (10.17) and (10.18). The contours of collapse load in Figure 10.6(b)<br />

show that the load increases along the leading diagonal of the map, with<br />

increasing c/ℓ and t/c.<br />

A similar map can be constructed for four-point bending; this is illustrated<br />

in Figure 10.7, for the same values a/ℓ D 0.1 and c y / f y<br />

D 0.005 as for three-<br />

point bending, but with the added parameter s/ℓ D 0.5. A comparison with the<br />

map of Figure 10.6(a) reveals that the domain of face yield shrinks slightly for<br />

four-point bending, and indentation almost disappears as a viable mechanism.<br />

Core shear dominates the map for the values of parameters selected.<br />

t<br />

c<br />

0.5<br />

10 −1<br />

3×10 −4<br />

1×10 −3<br />

1×10 −2<br />

3×10 −3<br />

2×10<br />

Indentation<br />

−2<br />

10−2 10−1 10<br />

0.5<br />

−2<br />

1×10<br />

Face<br />

Core<br />

shear<br />

yield<br />

−4<br />

F = 3×10−5 c/<br />

Indentation<br />

Figure 10.7 Collapse mechanism map for four-point bending, with<br />

flat-bottom indenters. Contours of non-dimensional collapse load<br />

F F/bℓ f y are plotted for the selected values c<br />

y / f and s/ℓ D 0.5<br />

y D 0.005, a/ℓ D 0.1<br />

Now, some words of caution. The collapse mechanisms described neglect<br />

elastic deformation and assume perfectly plastic behavior. Alternative failure<br />

modes are expected when the face sheets are made of a monolithic ceramic<br />

or composite layers, and behave in an elastic–brittle manner. Then, collapse<br />

is dictated by fracture of the face sheets, as analysed by Shuaeib and Soden<br />

(1997) and Soden (1996). The above treatment has been limited to the case<br />

of flat-bottomed indenters. An alternative practical case is the loading of<br />

sandwich beams by rollers, of radius R. This case is more complex because