Metal Foams: A Design Guide

Metal Foams: A Design Guide

Metal Foams: A Design Guide

- TAGS

- upload.vnuki.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

46 <strong>Metal</strong> <strong>Foams</strong>: A <strong>Design</strong> <strong>Guide</strong><br />

purposes, it is helpful to know that the tensile modulus Et of metal foams is<br />

not the same as that in compression Ec; the tensile modulus is greater, typically<br />

by 10%. Anisotropy of cell shape can lead to significant (30%) differences<br />

between moduli in different directions.<br />

Open-cells foams have a long, well-defined plateau stress, pl , visible on<br />

Figures 4.2 and 4.3. Here the cell edges are yielding in bending. Closed-cell<br />

foams show somewhat more complicated behavior which can cause the stress<br />

to rise with increasing strain because the cell faces carry membrane (tensile)<br />

stresses. The plateau continues up to the densification strain, εD, beyond which<br />

the structure compacts and the stress rises steeply. The plateau stress, pl, and<br />

the densification strain, εD, scale with density as:<br />

� �m � �<br />

pl ³ ⊲0.25 to 0.35⊳ y,s<br />

εD ³ 1 ˛1<br />

⊲4.2⊳<br />

s<br />

For currently available metfoams m lies between 1.5 and 2.0 and ˛1 between<br />

1.4 and 2. As a rule of thumb, m ³ 1.6 and˛1 ³ 1.5. These properties are<br />

important in energy-absorbing applications, to which metal foams lend themselves<br />

well (see Chapter 11).<br />

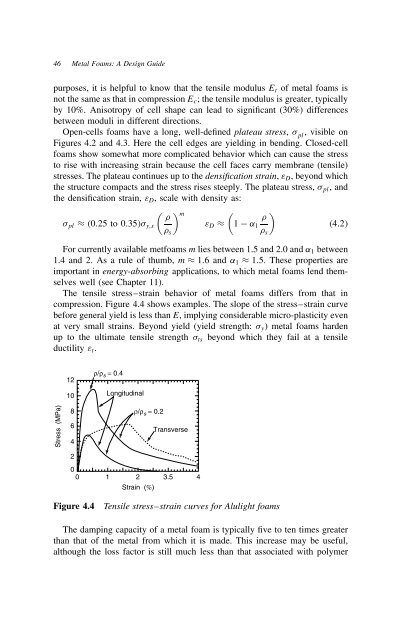

The tensile stress–strain behavior of metal foams differs from that in<br />

compression. Figure 4.4 shows examples. The slope of the stress–strain curve<br />

before general yield is less than E, implying considerable micro-plasticity even<br />

at very small strains. Beyond yield (yield strength: y) metal foams harden<br />

up to the ultimate tensile strength ts beyond which they fail at a tensile<br />

ductility εt.<br />

Stress (MPa)<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

ρ/ρ s = 0.4<br />

Longitudinal<br />

ρ/ρ s = 0.2<br />

0<br />

0 1 2 3.5 4<br />

Strain (%)<br />

Transverse<br />

Figure 4.4 Tensile stress–strain curves for Alulight foams<br />

The damping capacity of a metal foam is typically five to ten times greater<br />

than that of the metal from which it is made. This increase may be useful,<br />

although the loss factor is still much less than that associated with polymer<br />

s