- Page 1 and 2:

Metal Foams: A Design Guide

- Page 3 and 4:

Copyright © 2000 by Butterworth-He

- Page 5 and 6:

vi Contents 4.3 Foam property chart

- Page 7 and 8:

viii Contents 17 Case studies 217 1

- Page 9 and 10:

List of contributors M.F. Ashby Cam

- Page 11 and 12:

Table of physical constants and con

- Page 13 and 14:

Chapter 1 Introduction Metal foams

- Page 15 and 16:

Activity Research Industrial take-u

- Page 17 and 18:

Application Comment Introduction Bi

- Page 19 and 20:

Cell size (cm) Making metal foams 7

- Page 21 and 22:

Making metal foams solidify. The th

- Page 23 and 24:

Making metal foams 11 2.4 Gas-relea

- Page 25 and 26:

a) Preform Polymer ligaments d) Rem

- Page 27 and 28:

a) Vapor deposition of Nickel b) Bu

- Page 29 and 30:

Process Steps a) Powder / Can prepa

- Page 31 and 32:

Making metal foams 19 flight in a t

- Page 33 and 34:

a) Metal - Hydrogen binary phase di

- Page 35 and 36:

Entrapped gas expansion Making meta

- Page 37 and 38:

(a) (b) (c) 100µm Characterization

- Page 39 and 40:

E/E bulk σ peak /σ bulk 1.2 1.0 0

- Page 41 and 42:

Stress (MPa) Characterization metho

- Page 43 and 44:

Characterization methods 31 foam sp

- Page 45 and 46:

Characterization methods 33 ž Prop

- Page 47 and 48:

F/2 F/2 F/2 F/2 τ Core Characteriz

- Page 49 and 50:

Characterization methods 37 40 40 4

- Page 51 and 52:

Characterization methods 39 Gioux,

- Page 53 and 54:

(a) (b) (c) Properties of metal foa

- Page 55 and 56:

Table 4.1 (a) Ranges a for mechanic

- Page 57 and 58:

Stress, σ Schematic Young's modulu

- Page 59 and 60:

Properties of metal foams 47 foams.

- Page 61 and 62:

Properties of metal foams 49 show t

- Page 63 and 64:

Modulus 0.5 /Density (GPa 0.5 /(Mg/

- Page 65 and 66:

elations take the form P Ł � Ł

- Page 67 and 68:

Chapter 5 Design analysis for mater

- Page 69 and 70:

Table 5.1 Design requirements Desig

- Page 71 and 72:

Design analysis for material select

- Page 73 and 74:

5.4 Where might metal foams excel?

- Page 75 and 76:

Table 6.1 Constitutive equations fo

- Page 77 and 78:

h SECTION h o h i d d o a b ;;; QQQ

- Page 79 and 80:

6.3 Elastic deflection of beams and

- Page 81 and 82:

6.4 Failure of beams and panels (a)

- Page 83 and 84:

;; ;;; ;; M ;; ;;; ;; ;;; ;; ;; ;;

- Page 85 and 86:

Torsion of shafts T T,q T T,q Yield

- Page 87 and 88:

R a 2 Flow field R F R 2a 2 F F s c

- Page 89 and 90:

;; ; QQ Q ¢¢ ¢ ;; ;; QQ QQ ¢¢

- Page 91 and 92:

; ;; Creep p e p e • Area A u F 2

- Page 93 and 94:

and its deviatoric (i.e. shear) com

- Page 95 and 96:

Normalized effective stress 1.4 1.2

- Page 97 and 98:

A constitutive model for metal foam

- Page 99 and 100:

A constitutive model for metal foam

- Page 101 and 102:

Stress amplitude, ∆σ + Stress,

- Page 103 and 104:

Axial strain (%) 5 4 3 2 1 0 0 σma

- Page 105 and 106:

Nominal compressive strain Nominal

- Page 107 and 108: σ max σ pl τ max τ pl σ max σ

- Page 109 and 110: Design for fatigue with metal foams

- Page 111 and 112: the net section stress criterion re

- Page 113 and 114: E σ pl (m) 10 1 0.1 0.01 0.1 Relat

- Page 115 and 116: Chapter 9 Design for creep with met

- Page 117 and 118: Design for creep with metal foams 1

- Page 119 and 120: instead to: � Pε 3 D Pε0 2 s Ł

- Page 121 and 122: Time to failure (hours) 10 2 10 1 1

- Page 123 and 124: Design for creep with metal foams 1

- Page 125 and 126: Chapter 10 Sandwich structures Sand

- Page 127 and 128: Sandwich structures 115 The elastic

- Page 129 and 130: Indentation Sandwich structures 117

- Page 131 and 132: H H Core shear Core shear Collapse

- Page 133 and 134: 0.5 10−1 t c t c 10 −2 0.5 10

- Page 135 and 136: Sandwich structures 123 the contact

- Page 137 and 138: Sandwich structures 125 four sectio

- Page 139 and 140: c t p p Figure 10.9 Sandwich panel

- Page 141 and 142: Sandwich structures 129 with k ¾ D

- Page 143 and 144: c/ Face sheet yielding 0.14 0.12 0.

- Page 145 and 146: Weight index, ψ 10 −1 10 −2 10

- Page 147 and 148: Sandwich structures 135 To construc

- Page 149 and 150: Sandwich structures 137 The associa

- Page 151 and 152: Sandwich structures 139 Note that,

- Page 153 and 154: where D � 2⊲1 Eft 2 f ⊳GcR Sa

- Page 155 and 156: Weight index ψ = W/2πR 2 ρ s W c

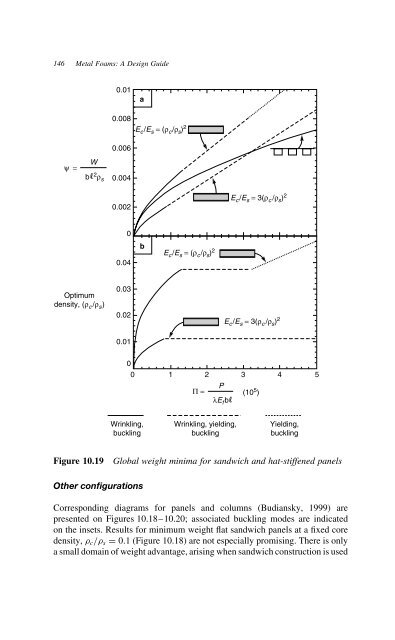

- Page 157: Sandwich structures 145 plastic yie

- Page 161 and 162: Sandwich structures 149 Shuaeib, F.

- Page 163 and 164: Energy management: packaging and bl

- Page 165 and 166: Energy management: packaging and bl

- Page 167 and 168: Energy/Unit cost (kJ/£) 10 1 0.1 0

- Page 169 and 170: Energy management: packaging and bl

- Page 171 and 172: ys crushes axially at the load Ener

- Page 173 and 174: Energy management: packaging and bl

- Page 175 and 176: Energy management: packaging and bl

- Page 177 and 178: Energy management: packaging and bl

- Page 179 and 180: peak pressure MPa Impulse/(mass of

- Page 181 and 182: Energy management: packaging and bl

- Page 183 and 184: Chapter 12 Sound absorption and vib

- Page 185 and 186: Sound absorption and vibration supp

- Page 187 and 188: Sound absorption and vibration supp

- Page 189 and 190: 0 Sound absorption and vibration su

- Page 191 and 192: Sound absorption and vibration supp

- Page 193 and 194: Chapter 13 Thermal management and h

- Page 195 and 196: Thermal management and heat transfe

- Page 197 and 198: Thermal management and heat transfe

- Page 199 and 200: ~ P ~ Re 2.6 1000 800 600 400 200 0

- Page 201 and 202: Chapter 14 Electrical properties of

- Page 203 and 204: Electrical properties of metal foam

- Page 205 and 206: Electrical properties of metal foam

- Page 207 and 208: 15.3 Joining of metal foams Cutting

- Page 209 and 210:

Pull-out load, F p (N) 10 5 10 4 10

- Page 211 and 212:

Cyclic loading of fasteners Cutting

- Page 213 and 214:

Time, material, energy, capital, in

- Page 215 and 216:

Cost estimation and viability 203 A

- Page 217 and 218:

$/Unit Melting Schematic of the liq

- Page 219 and 220:

Performance metric, P2 B Non-domina

- Page 221 and 222:

Cost estimation and viability 209 t

- Page 223 and 224:

Cost estimation and viability 211 i

- Page 225 and 226:

P 2 = 1/Loss coefficient (−) 1000

- Page 227 and 228:

Cost estimation and viability 215 C

- Page 229 and 230:

Chapter 17 Case studies Metal foams

- Page 231 and 232:

Case studies 219 Figure 17.2 A pres

- Page 233 and 234:

Case studies 221 Figure 17.4 Highwa

- Page 235 and 236:

Case studies 223 Figure 17.6 DUOCEL

- Page 237 and 238:

Case studies 225 density and high t

- Page 239 and 240:

Case studies 227 required for compa

- Page 241 and 242:

Maximum power density at electronic

- Page 243 and 244:

q *(MW/m 2) 15 10 Power density fix

- Page 245 and 246:

Case studies 233 which optimized sk

- Page 247 and 248:

e-mail: cymat@ican.net Web: www.cym

- Page 249 and 250:

Tel: C0043 7722 801-2125 Fax: C0043

- Page 251 and 252:

Chapter 19 Web sites An increasing

- Page 253 and 254:

http://www.seac.nl/english/recemat/

- Page 255 and 256:

(b) (continued) Appendix: Catalogue

- Page 257 and 258:

(f) Vibration-limited design Append

- Page 259 and 260:

Index (Company and trade names are

- Page 261 and 262:

Heat transfer 4, 182 Heat transfer

- Page 263:

Surface strain mapping 36 Syntactic