Metal Foams: A Design Guide

Metal Foams: A Design Guide

Metal Foams: A Design Guide

- TAGS

- upload.vnuki.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

164 <strong>Metal</strong> <strong>Foams</strong>: A <strong>Design</strong> <strong>Guide</strong><br />

quickly along the bar at an elastic wave speed cel D p E/ and brings the bar<br />

to a uniform stress of pl and to a negligibly small velocity of v D pl/⊲ cel⊳.<br />

Trailing behind this elastic wave is the more major disturbance of the plastic<br />

shock wave, travelling at a wave speed cpl. Upstream of the plastic shock<br />

front the stress is pl, and the velocity is vU ³ 0. Downstream of the shock<br />

the stress and strain state is given by the point D on the stress–strain curve:<br />

the compressive stress is D, the strain equals the densification strain, εD, and<br />

the foam density has increased to D D /⊲1 εD⊳.<br />

Momentum conservation for the plastic shock wave dictates that the stress<br />

jump ⊲ D pl⊳ across the shock is related to the velocity jump, vD, by<br />

�<br />

D<br />

�<br />

pl D cplvD ⊲11.16⊳<br />

and material continuity implies that the velocity jump, vD, is related to the<br />

strain jump, εD, by<br />

vD D cplεD<br />

⊲11.17⊳<br />

Elimination of vD from the above two relations gives the plastic wave speed,<br />

cpl:<br />

cpl D<br />

�<br />

⊲ D pl⊳<br />

εD<br />

This has the form<br />

cpl D<br />

�<br />

Et<br />

⊲11.18⊳<br />

⊲11.19⊳<br />

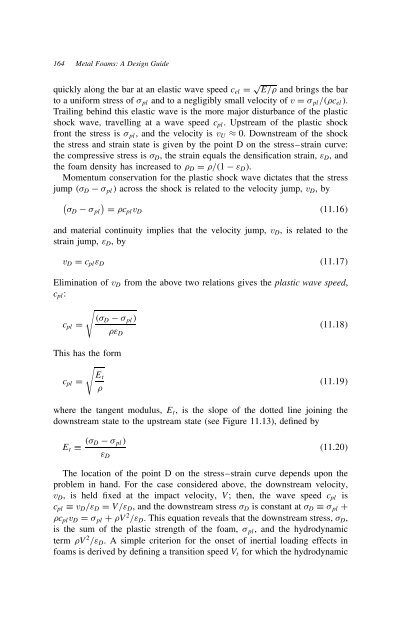

where the tangent modulus, Et, is the slope of the dotted line joining the<br />

downstream state to the upstream state (see Figure 11.13), defined by<br />

Et<br />

⊲ D pl⊳<br />

εD<br />

⊲11.20⊳<br />

The location of the point D on the stress–strain curve depends upon the<br />

problem in hand. For the case considered above, the downstream velocity,<br />

vD, is held fixed at the impact velocity, V; then, the wave speed cpl is<br />

cpl vD/εD D V/εD, and the downstream stress D is constant at D pl C<br />

cplvD D pl C V 2 /εD. This equation reveals that the downstream stress, D,<br />

is the sum of the plastic strength of the foam, pl, and the hydrodynamic<br />

term V 2 /εD. A simple criterion for the onset of inertial loading effects in<br />

foams is derived by defining a transition speed Vt for which the hydrodynamic