Metal Foams: A Design Guide

Metal Foams: A Design Guide

Metal Foams: A Design Guide

- TAGS

- upload.vnuki.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

P 2 = 1/Loss coefficient (−)<br />

100000.<br />

10000.<br />

1000.<br />

100.<br />

10.<br />

1.<br />

0.1<br />

Cost estimation and viability 213<br />

Performance metrics for<br />

stiffness and damping<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Low alloy ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

steels<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Nyoln<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

HDPE<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

CTFE PTFE<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

LLDPE<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Alcan<br />

Tungsten alloys<br />

Gunmetal<br />

Trade-off<br />

surface<br />

Bronzes<br />

Brasses<br />

Alulight<br />

Alporas<br />

Titanium<br />

Melamine<br />

UPVC<br />

alloys<br />

Aluminum<br />

PEEK<br />

alloys<br />

Megnesium<br />

alloys<br />

Cast irons Tin alloys<br />

Sn-Sb alloys<br />

Lead alloys<br />

Pure lead<br />

MDPE<br />

Ionomer (IO) LDPE<br />

1.<br />

P 1 = Density/modulus (Mg/m 3 /GPa)<br />

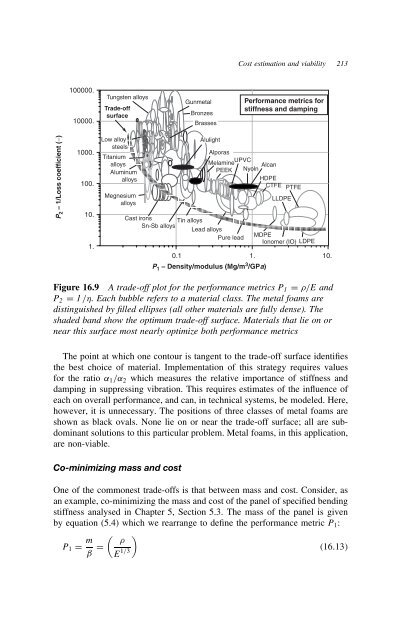

Figure 16.9 A trade-off plot for the performance metrics P1 D /E and<br />

P2 D 1 / . Each bubble refers to a material class. The metal foams are<br />

distinguished by filled ellipses (all other materials are fully dense). The<br />

shaded band show the optimum trade-off surface. Materials that lie on or<br />

near this surface most nearly optimize both performance metrics<br />

The point at which one contour is tangent to the trade-off surface identifies<br />

the best choice of material. Implementation of this strategy requires values<br />

for the ratio ˛1/˛2 which measures the relative importance of stiffness and<br />

damping in suppressing vibration. This requires estimates of the influence of<br />

each on overall performance, and can, in technical systems, be modeled. Here,<br />

however, it is unnecessary. The positions of three classes of metal foams are<br />

shown as black ovals. None lie on or near the trade-off surface; all are subdominant<br />

solutions to this particular problem. <strong>Metal</strong> foams, in this application,<br />

are non-viable.<br />

Co-minimizing mass and cost<br />

One of the commonest trade-offs is that between mass and cost. Consider, as<br />

an example, co-minimizing the mass and cost of the panel of specified bending<br />

stiffness analysed in Chapter 5, Section 5.3. The mass of the panel is given<br />

by equation (5.4) which we rearrange to define the performance metric P1:<br />

P1 D m<br />

ˇ D<br />

� �<br />

⊲16.13⊳<br />

E 1/3<br />

10.