Metal Foams: A Design Guide

Metal Foams: A Design Guide

Metal Foams: A Design Guide

- TAGS

- upload.vnuki.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

214 <strong>Metal</strong> <strong>Foams</strong>: A <strong>Design</strong> <strong>Guide</strong><br />

with ˇ given by<br />

ˇ D<br />

� �<br />

Ł 2<br />

1/3<br />

12S b<br />

ℓ<br />

C1<br />

2<br />

⊲16.14⊳<br />

ˇ is a constant for a given design, and does not influence the optimization.<br />

The geometric constant, C1, defined in equation (5.4), depends only on the<br />

distribution of loads on the panel and does not influence the subsequent argument.<br />

The cost, Cp, of the panel is simply the material cost per kg, C (from<br />

equation (16.4)), times the mass m, giving the second performance metric P2:<br />

P2 D Cp<br />

ˇ D<br />

� C<br />

E 1/3<br />

�<br />

⊲16.15⊳<br />

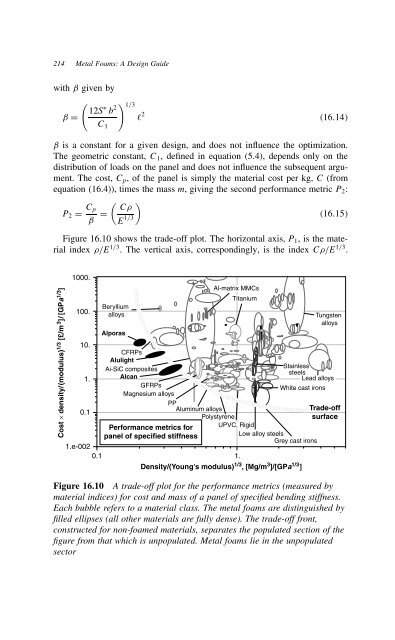

Figure 16.10 shows the trade-off plot. The horizontal axis, P1, isthematerial<br />

index /E 1/3 . The vertical axis, correspondingly, is the index C /E 1/3 .<br />

Cost × density/(modulus) 1/3 [£/m 3 ]/ [GPa 1/3 ]<br />

1000.<br />

100.<br />

10.<br />

1.<br />

0.1<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Al-matrix MMCs<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Titanium<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Beryllium ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

alloys ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Tungsten<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; alloys<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Alporas ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

CFRPs ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Alulight ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Ai-SiC composites ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; Stainless<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; steels<br />

Alcan ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; Lead alloys<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

GFRPs<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

White cast irons<br />

Magnesium ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

alloys<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

PP<br />

Aluminum alloys<br />

Trade-off<br />

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;<br />

Polystyrene<br />

surface<br />

Performance metrics for UPVC, Rigid<br />

1.e-002<br />

panel of specified stiffness<br />

Low alloy steels<br />

Grey cast irons<br />

0.1<br />

1.<br />

Density/(Young's modulus) 1/3 , [Mg/m 3 ]/[GPa 1/3 ]<br />

Figure 16.10 A trade-off plot for the performance metrics (measured by<br />

material indices) for cost and mass of a panel of specified bending stiffness.<br />

Each bubble refers to a material class. The metal foams are distinguished by<br />

filled ellipses (all other materials are fully dense). The trade-off front,<br />

constructed for non-foamed materials, separates the populated section of the<br />

figure from that which is unpopulated. <strong>Metal</strong> foams lie in the unpopulated<br />

sector