Metal Foams: A Design Guide

Metal Foams: A Design Guide

Metal Foams: A Design Guide

- TAGS

- upload.vnuki.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Characterization methods 33<br />

ž Proportional axisymmetric stress paths are explored in the following way.<br />

The direction of stressing is defined by the relation m D e, with the<br />

D (for uniaxial compression)<br />

3<br />

1<br />

parameter taking values over the range<br />

to D1(for hydrostatic compression). In a typical proportional loading<br />

experiment, the hydrostatic pressure and the axial load are increased in<br />

small increments keeping constant. The axial displacement are measured<br />

at each load increment and are used to define the axial strain.<br />

Yield surface measurements<br />

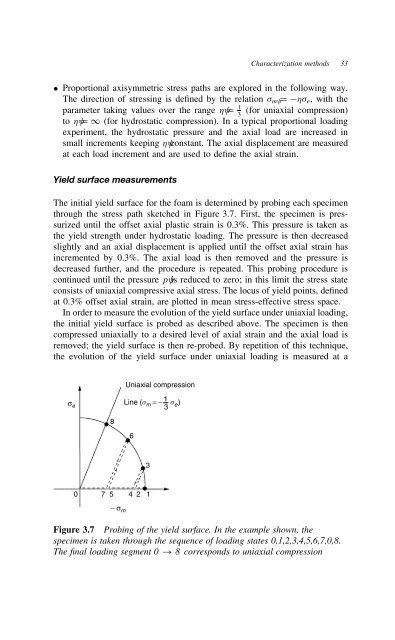

The initial yield surface for the foam is determined by probing each specimen<br />

through the stress path sketched in Figure 3.7. First, the specimen is pressurized<br />

until the offset axial plastic strain is 0.3%. This pressure is taken as<br />

the yield strength under hydrostatic loading. The pressure is then decreased<br />

slightly and an axial displacement is applied until the offset axial strain has<br />

incremented by 0.3%. The axial load is then removed and the pressure is<br />

decreased further, and the procedure is repeated. This probing procedure is<br />

continued until the pressure p is reduced to zero; in this limit the stress state<br />

consists of uniaxial compressive axial stress. The locus of yield points, defined<br />

at 0.3% offset axial strain, are plotted in mean stress-effective stress space.<br />

In order to measure the evolution of the yield surface under uniaxial loading,<br />

the initial yield surface is probed as described above. The specimen is then<br />

compressed uniaxially to a desired level of axial strain and the axial load is<br />

removed; the yield surface is then re-probed. By repetition of this technique,<br />

the evolution of the yield surface under uniaxial loading is measured at a<br />

σ e<br />

8<br />

6<br />

3<br />

0 7 5 4 2 1<br />

− σ m<br />

Uniaxial compression<br />

Line (sm = −<br />

1<br />

s<br />

3<br />

e)<br />

Figure 3.7 Probing of the yield surface. In the example shown, the<br />

specimen is taken through the sequence of loading states 0,1,2,3,4,5,6,7,0,8.<br />

The final loading segment 0 ! 8 corresponds to uniaxial compression