sejal architectural glass limited - Securities and Exchange Board of ...

sejal architectural glass limited - Securities and Exchange Board of ...

sejal architectural glass limited - Securities and Exchange Board of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

As the batch materials melt into solution, the molten <strong>glass</strong> would be gradually cooled in<br />

the refiner section <strong>of</strong> the furnace. By the time the <strong>glass</strong> would reach the furnace front<br />

wall, it would be completely free <strong>of</strong> unmelted batch particles <strong>and</strong> uniform in composition.<br />

This homogeneous blend would now be delivered to the Metal Bath in a continuous flow<br />

through the canal.<br />

(b) Metal Bath: The metal bath would consist <strong>of</strong> an electrically heated forming oven. The<br />

molten <strong>glass</strong> would flow onto the surface <strong>of</strong> a pool <strong>of</strong> molten tin, maintained at<br />

approximately 1000 °C to 1100°C. A continuous ribbon would be drawn from this pool <strong>and</strong><br />

transported <strong>and</strong> cooled along the length <strong>of</strong> the Metal Bath. The s<strong>of</strong>t <strong>glass</strong> at the bath exit<br />

would be approximately 600 °c hot <strong>and</strong> still in plastic stage but hard enough to be removed<br />

from the surface <strong>of</strong> the tin with mechanical rollers without marking. The Metal bath would<br />

be approximately 7 meters wide <strong>and</strong> 50 meter long, containing close to 130 tons to 145<br />

tons <strong>of</strong> molten tin. The bath chamber would be carefully sealed <strong>and</strong> maintained under<br />

positive pressure by an inert nitrogen atmosphere with traces <strong>of</strong> hydrogen. This is<br />

necessary to maintain a clean pristine surface for the tin, which would otherwise rapidly<br />

oxidize in air. The molten <strong>glass</strong>, when flowing on the surface <strong>of</strong> the molten tin, forms a<br />

ribbon <strong>of</strong> perfectly flat parallel surface. The thickness <strong>of</strong> the ribbon is controlled by the<br />

pull out speed <strong>and</strong> can vary from 2mm to 12mm. The ribbon would emerge from the bath<br />

at different speeds depending upon the desired thickness.<br />

(c) Annealing Lehr: The Annealing lehr must cool the <strong>glass</strong> ribbon from 600°C to<br />

approximately 90°C, in a precise uniform manner to prevent residual stresses that make<br />

cutting difficult <strong>and</strong> also to prevent temporary stresses that cause ribbon fractures. The<br />

Annealing lehr would use small amounts <strong>of</strong> electric heat to keep the edge <strong>of</strong> the sheet from<br />

cooling faster than the center. Special rollers <strong>and</strong> drive systems are required for the<br />

Annealing lehr, as well as a sophisticated temperature control system to accomplish<br />

controlled cooling.<br />

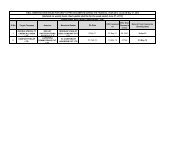

Collaborations/Tie-up/Association/Other agreements<br />

1. Memor<strong>and</strong>um <strong>of</strong> Underst<strong>and</strong>ing between Sejal Architectural Glass Limited <strong>and</strong><br />

Flaschglas Veredlung GmbH & Co. KG., Germany<br />

Parties to the<br />

Agreement<br />

Date <strong>of</strong> the<br />

Agreement<br />

Nature <strong>of</strong> the<br />

Agreement<br />

Sejal Architectural Glass Limited (SAGL) <strong>and</strong> Flaschglas-Veredlung<br />

GmbH & Co. KG, Germany (Arcon) represented by Kaphs SA-<br />

Switzerl<strong>and</strong> (Kaphs SA).<br />

September 25, 2006<br />

Memor<strong>and</strong>um <strong>of</strong> Underst<strong>and</strong>ing wherein arcon will give its products to<br />

SAGL for final processing. SAGL will also give its own br<strong>and</strong> name to<br />

these products i.e. Fresca Gold <strong>and</strong> Fresca Platinum. These products<br />

have been developed with the technical support <strong>and</strong> guidance <strong>of</strong><br />

arcon.<br />

Validity This Memor<strong>and</strong>um <strong>of</strong> Underst<strong>and</strong>ing is valid for 3 years with effect<br />

from July 7, 2006.<br />

Renewal Clause It will be revised based on the targets achieved.<br />

Non-Compete/Nonsolicit<br />

clause<br />

Arcon will not participate in any <strong>of</strong> the <strong>glass</strong> exhibitions in India.<br />

Secrecy/Non<br />

disclosure clause<br />

None<br />

Termination clause Termination<br />

If the targeted volume, agreed by SAGL, is not achieved, arcon will be<br />

103