VGB POWERTECH 10 (2019)

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 10 (2019). Technical Journal of the VGB PowerTech Association. Energy is us! Cyber security. Power generation. Environment. Flexibility.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 10 (2019).

Technical Journal of the VGB PowerTech Association. Energy is us!

Cyber security. Power generation. Environment. Flexibility.

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Heat storage systems<br />

A journey through <strong>10</strong>0 years <strong>VGB</strong> | <strong>VGB</strong><br />

<strong>VGB</strong><br />

<strong>POWERTECH</strong><br />

PowerTech 1/2<br />

1/2<br />

l 2013<br />

(2013)<br />

electric<br />

storage<br />

– electric<br />

field energy<br />

– magnetic<br />

field energy<br />

– potential<br />

energy<br />

– kinetic<br />

energy<br />

Energy storage system<br />

mechanial<br />

storage<br />

chemical<br />

storage<br />

thermal<br />

storage<br />

– fuels – heat storage<br />

2<br />

3 4 6 7<br />

5<br />

M<br />

G<br />

K 1 K<br />

8<br />

1 engine/generator<br />

2 compressor<br />

3 cooler<br />

4,6 valve<br />

5 underground cavern<br />

7 combustion chamber<br />

8 gas turbine<br />

K coupling<br />

Fig. 1. Energy storage systems.<br />

Fig. 3. Compressed-air storage power plant.<br />

merous applications in electricity networks<br />

(in isolated networks, as backup solutions<br />

for power outage conditions, etc.), “E-mobility”<br />

and “vehicle-to-grid” concepts are<br />

being met with great interest. In summary<br />

and based on the data available on output<br />

(MW), capacity (MWh), energy efficiency<br />

(self-discharge rates, energy loss, etc.) and<br />

long-term experience with this type of application,<br />

however, it must be stated that<br />

accumulator systems are obviously not<br />

very commonly used in power plants and<br />

power supply systems for storing energy on<br />

a large scale.<br />

Mechanical energy storage [7]<br />

Pumped-storage power plants (F i g u r e 2)<br />

are typical examples of mechanical energy<br />

storage systems.<br />

Usually, this concept uses the difference in<br />

altitude between an upper reservoir and a<br />

lower reservoir in order to generate power<br />

in water turbines in combination with<br />

generators. This principle is utilised often<br />

in periods of high power demand (peak<br />

load demand). For this purpose, the upper<br />

reservoir is filled by powerful pumps during<br />

times when sufficient power supply is<br />

available and inexpensive. Besides the criteria<br />

relevant to the necessary difference in<br />

altitude between the upper and the lower<br />

reservoir (normally in mountain areas),<br />

especially the local requirements regarding<br />

water resources, environment and nature<br />

conservation, as well as the possible grid<br />

connection need to be taken into account.<br />

Numerous large-scale plants of this type<br />

valve<br />

pump<br />

coupling<br />

upper reservoir<br />

M<br />

G<br />

lower reservoir<br />

valve<br />

turbine<br />

coupling<br />

Fig. 2. Pumped storage power plant.<br />

h<br />

have been installed all over the world and<br />

are delivering outputs of ⪢<strong>10</strong>0 MW and capacities<br />

of >1,000 MWh. Positive technical<br />

operating experience has been gathered<br />

and documented for more than <strong>10</strong>0 years.<br />

The projects currently discussed in Germany<br />

and Europe are primarily affected<br />

by the issues of environmental protection<br />

and nature conservation [8]. In addition,<br />

the economical and regulatory framework<br />

for investors and plant owners are<br />

presently not positive and/or long-range<br />

planning is difficult [9 to 12]. However,<br />

with respect to their output (MW), capacity<br />

(MWh), energy efficiency (plant efficiency,<br />

energy losses) and proven scope of<br />

application, pumped-storage power plants<br />

can be viewed as the storage system most<br />

frequently used in the world that is capable<br />

of storing large amounts of energy in<br />

connection with major power plants and<br />

power supply systems.<br />

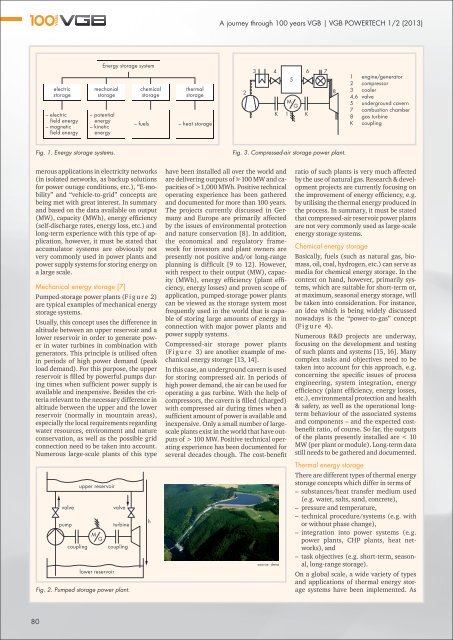

Compressed-air storage power plants<br />

(F i g u r e 3) are another example of mechanical<br />

energy storage [13, 14].<br />

In this case, an underground cavern is used<br />

for storing compressed air. In periods of<br />

high power demand, the air can be used for<br />

operating a gas turbine. With the help of<br />

compressors, the cavern is filled (charged)<br />

with compressed air during times when a<br />

sufficient amount of power is available and<br />

inexpensive. Only a small number of largescale<br />

plants exist in the world that have outputs<br />

of > <strong>10</strong>0 MW. Positive technical operating<br />

experience has been documented for<br />

several decades though. The cost-benefit<br />

source: dena<br />

ratio of such plants is very much affected<br />

by the use of natural gas. Research & development<br />

projects are currently focusing on<br />

the improvement of energy efficiency, e.g.<br />

by utilising the thermal energy produced in<br />

the process. In summary, it must be stated<br />

that compressed-air reservoir power plants<br />

are not very commonly used as large-scale<br />

energy storage systems.<br />

Chemical energy storage<br />

Basically, fuels (such as natural gas, biomass,<br />

oil, coal, hydrogen, etc.) can serve as<br />

media for chemical energy storage. In the<br />

context on hand, however, primarily systems,<br />

which are suitable for short-term or,<br />

at maximum, seasonal energy storage, will<br />

be taken into consideration. For instance,<br />

an idea which is being widely discussed<br />

nowadays is the “power-to-gas” concept<br />

(Figure 4).<br />

Numerous R&D projects are underway,<br />

focusing on the development and testing<br />

of such plants and systems [15, 16]. Many<br />

complex tasks and objectives need to be<br />

taken into account for this approach, e.g.<br />

concerning the specific issues of process<br />

engineering, system integration, energy<br />

efficiency (plant efficiency, energy losses,<br />

etc.), environmental protection and health<br />

& safety, as well as the operational longterm<br />

behaviour of the associated systems<br />

and components – and the expected costbenefit<br />

ratio, of course. So far, the outputs<br />

of the plants presently installed are < <strong>10</strong><br />

MW (per plant or module). Long-term data<br />

still needs to be gathered and documented.<br />

Thermal energy storage<br />

There are different types of thermal energy<br />

storage concepts which differ in terms of<br />

– substances/heat transfer medium used<br />

(e.g. water, salts, sand, concrete),<br />

– pressure and temperature,<br />

– technical procedure/systems (e.g. with<br />

or without phase change),<br />

– integration into power systems (e.g.<br />

power plants, CHP plants, heat networks),<br />

and<br />

– task objectives (e.g. short-term, seasonal,<br />

long-range storage).<br />

On a global scale, a wide variety of types<br />

and applications of thermal energy storage<br />

systems have been implemented. As<br />

70<br />

80