VGB POWERTECH 10 (2019)

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 10 (2019). Technical Journal of the VGB PowerTech Association. Energy is us! Cyber security. Power generation. Environment. Flexibility.

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 10 (2019).

Technical Journal of the VGB PowerTech Association. Energy is us!

Cyber security. Power generation. Environment. Flexibility.

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Heat storage systems<br />

A journey through <strong>10</strong>0 years <strong>VGB</strong> | <strong>VGB</strong><br />

<strong>VGB</strong><br />

<strong>POWERTECH</strong><br />

PowerTech 1/2<br />

1/2<br />

l 2013<br />

(2013)<br />

Table 2. Data of Münster pressurised<br />

water storage).<br />

Height<br />

Diameter<br />

28 m<br />

<strong>10</strong> m<br />

Storage capacity 8,000 m 3 /<br />

up to 545 MWh<br />

Max. temperature 120 °C<br />

GKM water heat storage system<br />

Grosskraftwerk Mannheim AG (GKM) is<br />

a joint-venture power generation plant of<br />

RWE, EnBW, and MVV [19]. The CHP units<br />

of GKM are generating 50 Hz power for the<br />

public electricity network, 16.7 Hz railway<br />

power for DB Energie (German railways),<br />

and district heat for the MVV utility company.<br />

F i g u r e 11 shows the Mannheim<br />

district heat system which is fed with heat<br />

from the GKM plant.<br />

Based on thorough investigation and comparative<br />

analyses which were carried out<br />

in order to identify the options for operational<br />

optimisation of the CHP units in the<br />

GKM, the decision was taken to install a<br />

non-pressurised district-heat storage unit.<br />

F i g u r e 12 shows a simplified process<br />

flow diagram of the GKM water heat storage<br />

system.<br />

The centrepiece of the system is the storage<br />

tank based on the “System Dr. Hedsource:<br />

Stadtwerke Münster<br />

Fig. 8. Münster pressurised water storage.<br />

around the world. Further R&D activity focusing<br />

on the improvement of such systems<br />

is advisable.<br />

Thermal storage/water and steam/<br />

Ruths’ storage system<br />

In most of the technical applications being<br />

used internationally for thermal energy<br />

storage, water and steam are the primary<br />

media. The Ruths’ storage system (F i g -<br />

u r e 7) has been in use for decades now,<br />

mainly in power plants, industrial plants,<br />

and locomotives.<br />

The Ruths’ steam storage system is characterised<br />

by:<br />

– simple construction/easy to integrate in<br />

power plants,<br />

– water/steam system (well known),<br />

– positive long-term experience,<br />

– high temperature range (up to 300 °C),<br />

– good capacity (MW),<br />

limited volume (MWh),<br />

– sliding pressure,<br />

– periodic official pressure tests necessary,<br />

and<br />

– relatively high investment costs.<br />

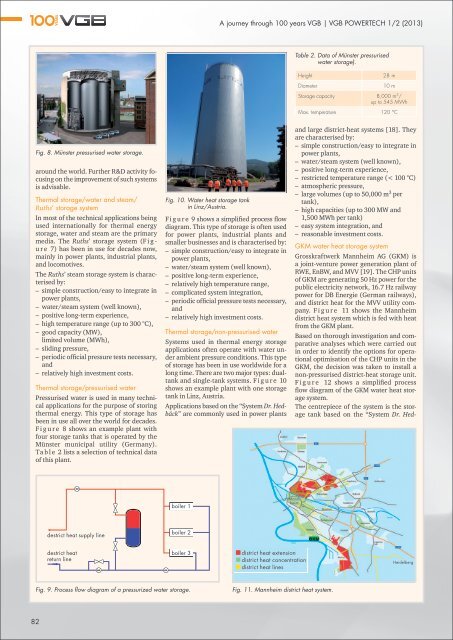

Thermal storage/pressurised water<br />

Pressurised water is used in many technical<br />

applications for the purpose of storing<br />

thermal energy. This type of storage has<br />

been in use all over the world for decades.<br />

F i g u r e 8 shows an example plant with<br />

four storage tanks that is operated by the<br />

Münster municipal utility (Germany).<br />

Ta b l e 2 lists a selection of technical data<br />

of this plant.<br />

Fig. <strong>10</strong>. Water heat storage tank<br />

in Linz/Austria.<br />

F i g u r e 9 shows a simplified process flow<br />

diagram. This type of storage is often used<br />

for power plants, industrial plants and<br />

smaller businesses and is characterised by:<br />

– simple construction/easy to integrate in<br />

power plants,<br />

– water/steam system (well known),<br />

– positive long-term experience,<br />

– relatively high temperature range,<br />

– complicated system integration,<br />

– periodic official pressure tests necessary,<br />

and<br />

– relatively high investment costs.<br />

Thermal storage/non-pressurised water<br />

Systems used in thermal energy storage<br />

applications often operate with water under<br />

ambient pressure conditions. This type<br />

of storage has been in use worldwide for a<br />

long time. There are two major types: dualtank<br />

and single-tank systems. F i g u r e <strong>10</strong><br />

shows an example plant with one storage<br />

tank in Linz, Austria.<br />

Applications based on the “System Dr. Hedbäck”<br />

are commonly used in power plants<br />

and large district-heat systems [18]. They<br />

are characterised by:<br />

– simple construction/easy to integrate in<br />

power plants,<br />

– water/steam system (well known),<br />

– positive long-term experience,<br />

– restricted temperature range (< <strong>10</strong>0 °C)<br />

– atmospheric pressure,<br />

– large volumes (up to 50,000 m 3 per<br />

tank),<br />

– high capacities (up to 300 MW and<br />

1,500 MWh per tank)<br />

– easy system integration, and<br />

– reasonable investment costs.<br />

boiler 1<br />

Mannheim<br />

destrict heat supply line<br />

boiler 2<br />

destrict heat<br />

return line<br />

boiler 3<br />

district heat extension<br />

district heat concentration<br />

district heat lines<br />

Heidelberg<br />

Fig. 9. Process flow diagram of a pressurized water storage.<br />

Fig. 11. Mannheim district heat system.<br />

72<br />

82